Two-stage spraying temperature-returning pretreatment system for fat-rich combustion waste gas

A combustion waste gas and pretreatment technology, which is applied in the field of flue gas treatment devices and flue gas pretreatment devices, can solve the problems of unconsidered pollutants and unspecified safe range of pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

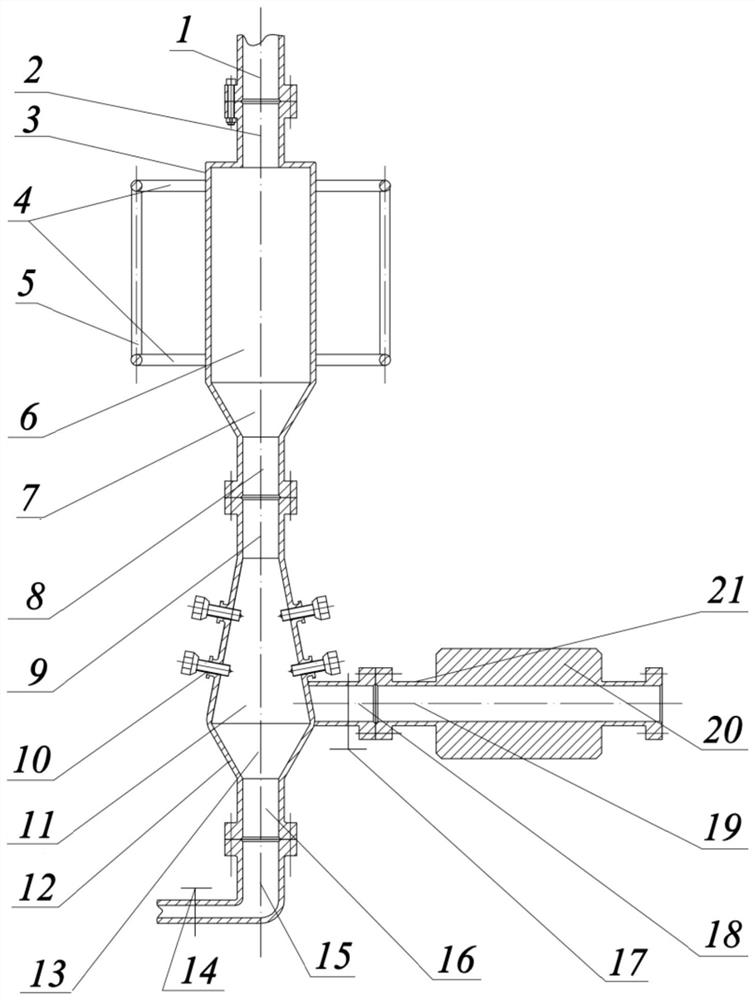

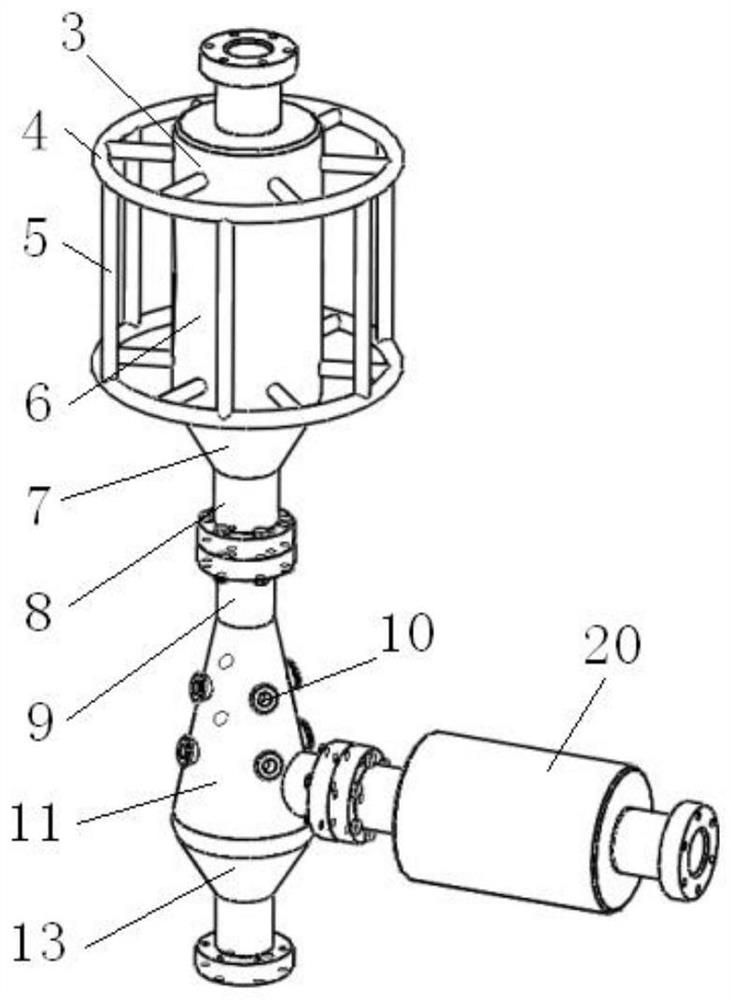

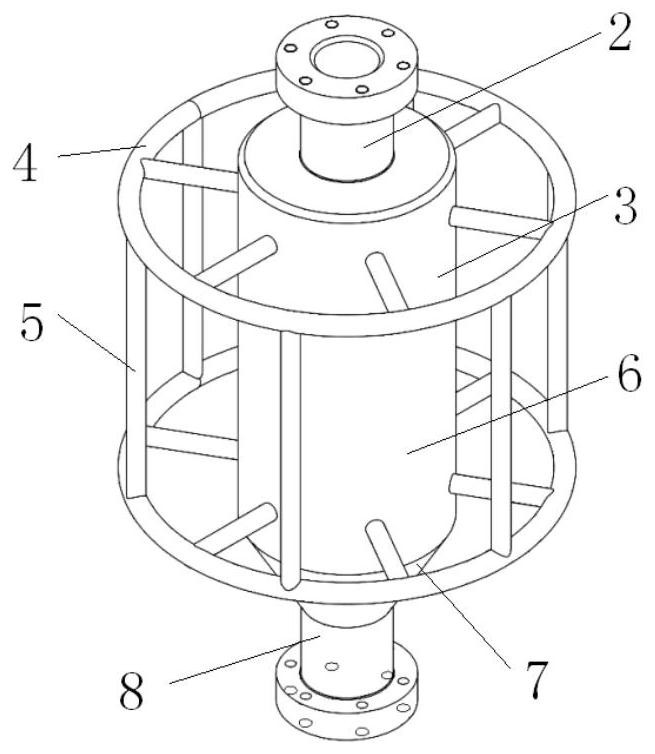

[0037] Such as Figure 1 to Figure 3 As shown, the present invention proposes a two-stage spray temperature return pretreatment system for fat-rich combustion exhaust gas, including a primary spray cooling device 3 and a secondary spray cooling device sequentially connected to the exhaust pipe 1 of the incineration equipment 12 and temperature return device 21.

[0038] Such as Figure 1 to Figure 3 As shown, the first-stage spray cooling device 3 includes a waste gas inlet pipe 2 connected from top to bottom, a straight pipe cavity 6, a narrowing bell mouth 7 and an outlet pipe 8; the periphery of the straight pipe cavity 6 A plurality of groups of outer spray nozzles that are evenly distributed along the circumferential direction from top to bottom through the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com