Grouting device for well drilling

A drilling and mud technology, which is applied in the field of drilling grouting devices, can solve the problems of easily induced overflow, cumbersome grouting process, and inaccurate measurement of the amount of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

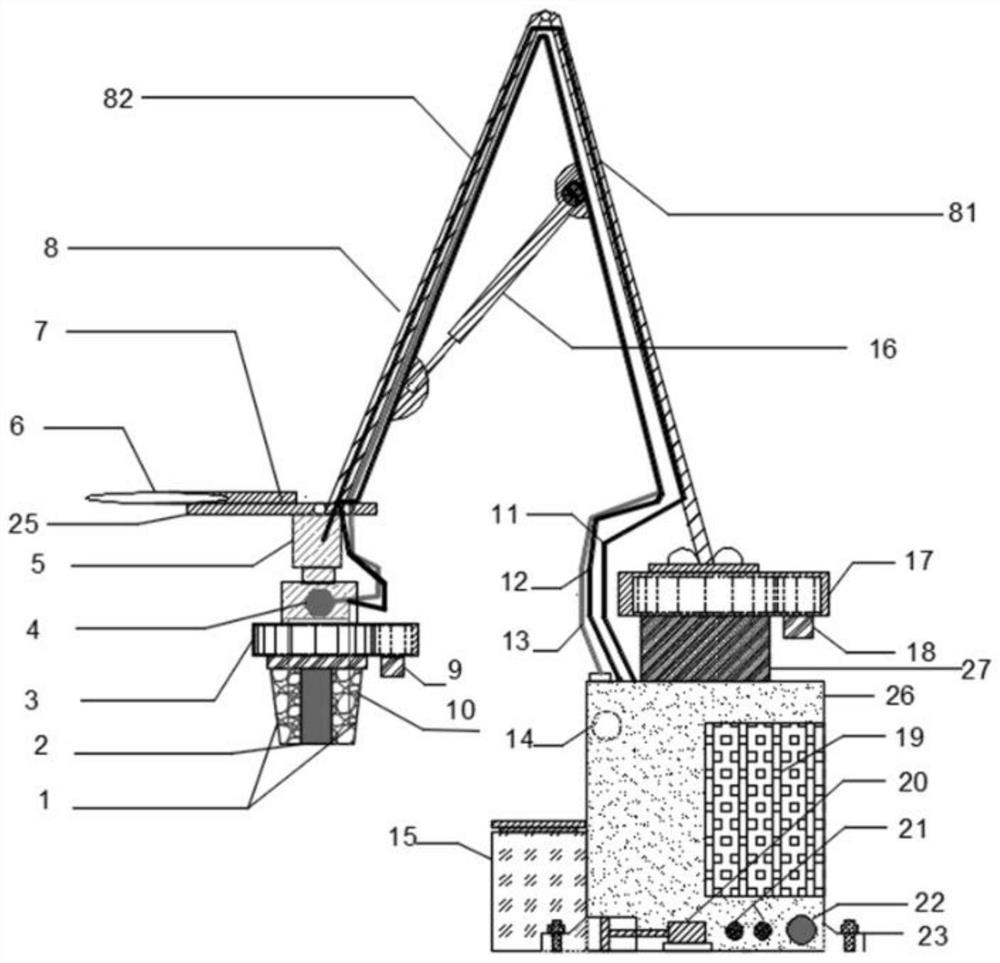

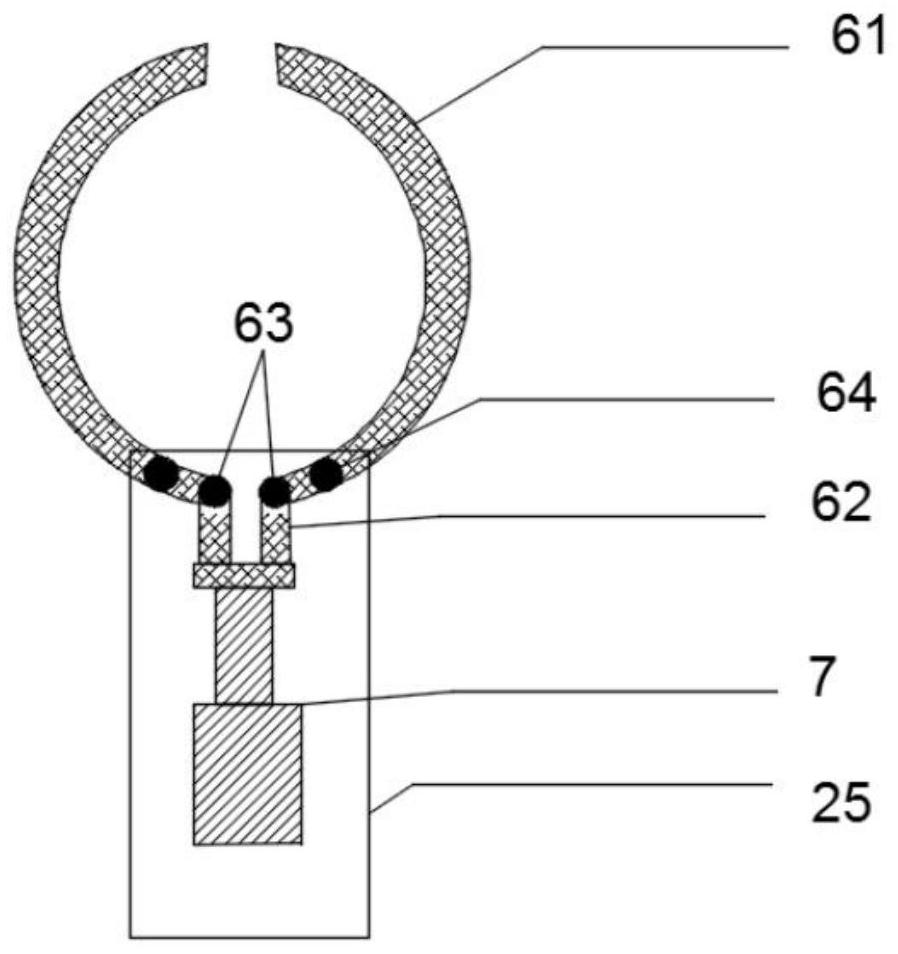

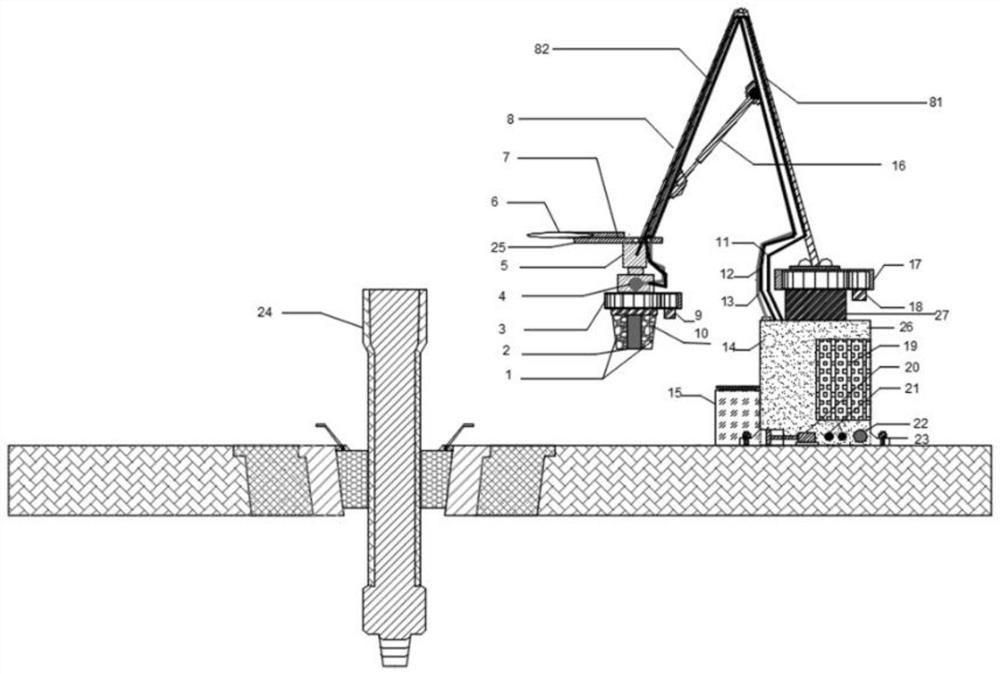

[0023] A grouting device for drilling, such as figure 1 As shown, it includes a mechanical arm 8 and a driving platform for driving the mechanical arm 8, the driving platform drives the expansion and contraction of the mechanical arm 8, and controls the action angle of the mechanical arm 8; it also includes a base hinged with the end of the mechanical arm 8 away from the driving platform 25 and the gripping structure and grouting structure connected to the base 25; the gripping structure includes the drill jaw 6 connected to the base 25 and the first hydraulic cylinder 7 for driving the drill jaw 6 to open and close. In the embodiment, the surface where the base 25 and the mechanical arm 8 are hinged is the upper surface, the drilling tool jaws 6 are installed on the upper surface of the base 25, and the jaws of the drilling tool jaws 6 to realize the grasping function are outside the upper surface of the base 25 , the first hydraulic cylinder 7 can be installed on the same si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com