Liquid drop wall hitting experiment device and method

An experimental device and droplet technology, applied in the direction of measuring devices, instruments, internal combustion engine testing, etc., can solve the problems such as the internal working conditions of the engine are far apart, and achieve the effects of low cost, timely feedback, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

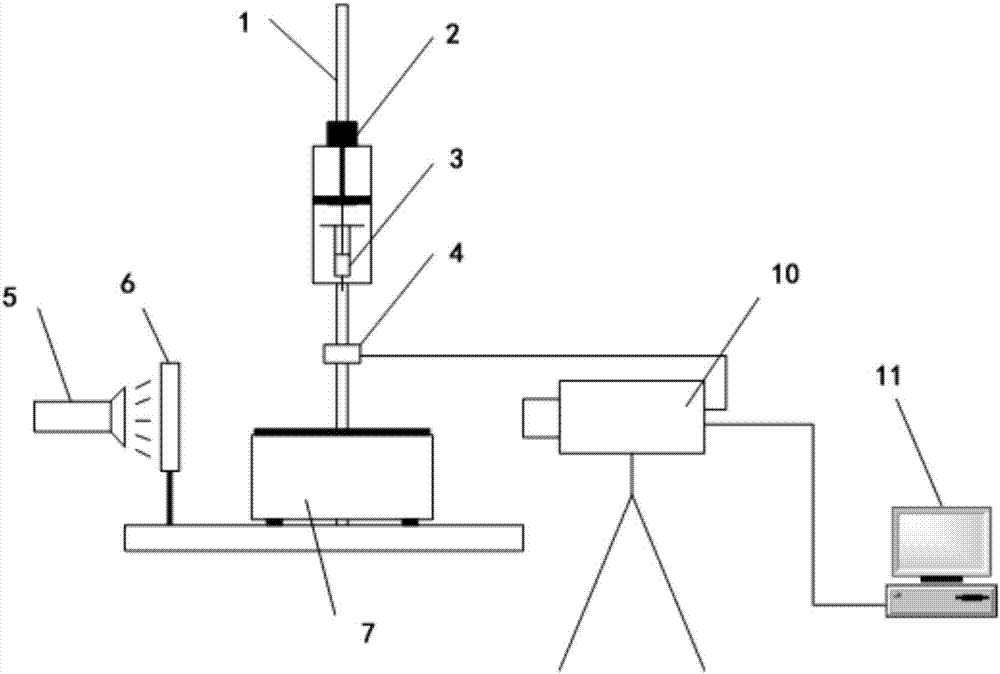

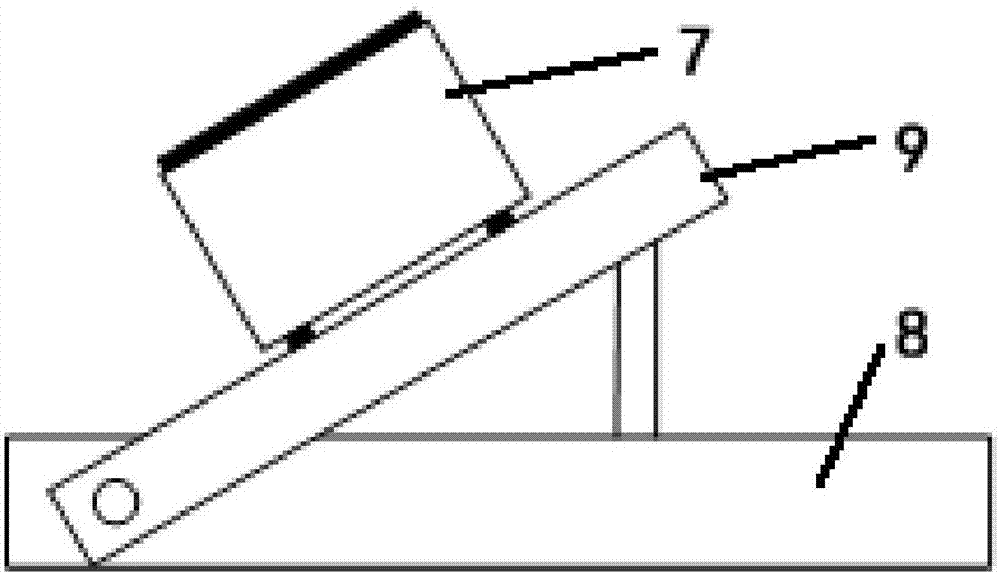

[0036] First of all, the present invention provides a droplet collision experiment device, which includes: a droplet injection system, a heating system, a visualization system and a signal control system, the heating system includes a tilt table 9 that can change the tilt angle, and the tilt table 9 Place the constant temperature heating platform 7 that can change the heating temperature.

[0037] The droplet injection system includes a bracket 1 supporting the droplet injection system, a stepping motor of the syringe pump set on the bracket 1, a syringe stand driven by the stepping motor of the syringe pump, and a replaceable syringe 3 installed on the syringe stand .

[0038] The dripping of the syringe 3 is controlled by driving the syringe stand through the stepping motor of the syringe pump; the droplet size is controlled by changing the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com