Iron tower bolt defect display method and system based on three-dimensional live-action model

A technology of real scene model and three-dimensional model, which is applied in the direction of radio wave measurement system, optical test defect/defect, satellite radio beacon positioning system, etc., can solve the problem that the detection result is affected by human factors, etc., to improve the efficiency of acceptance work, Reduce work input and reduce the effect of tower failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

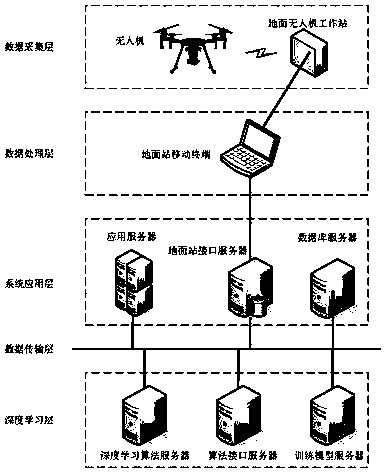

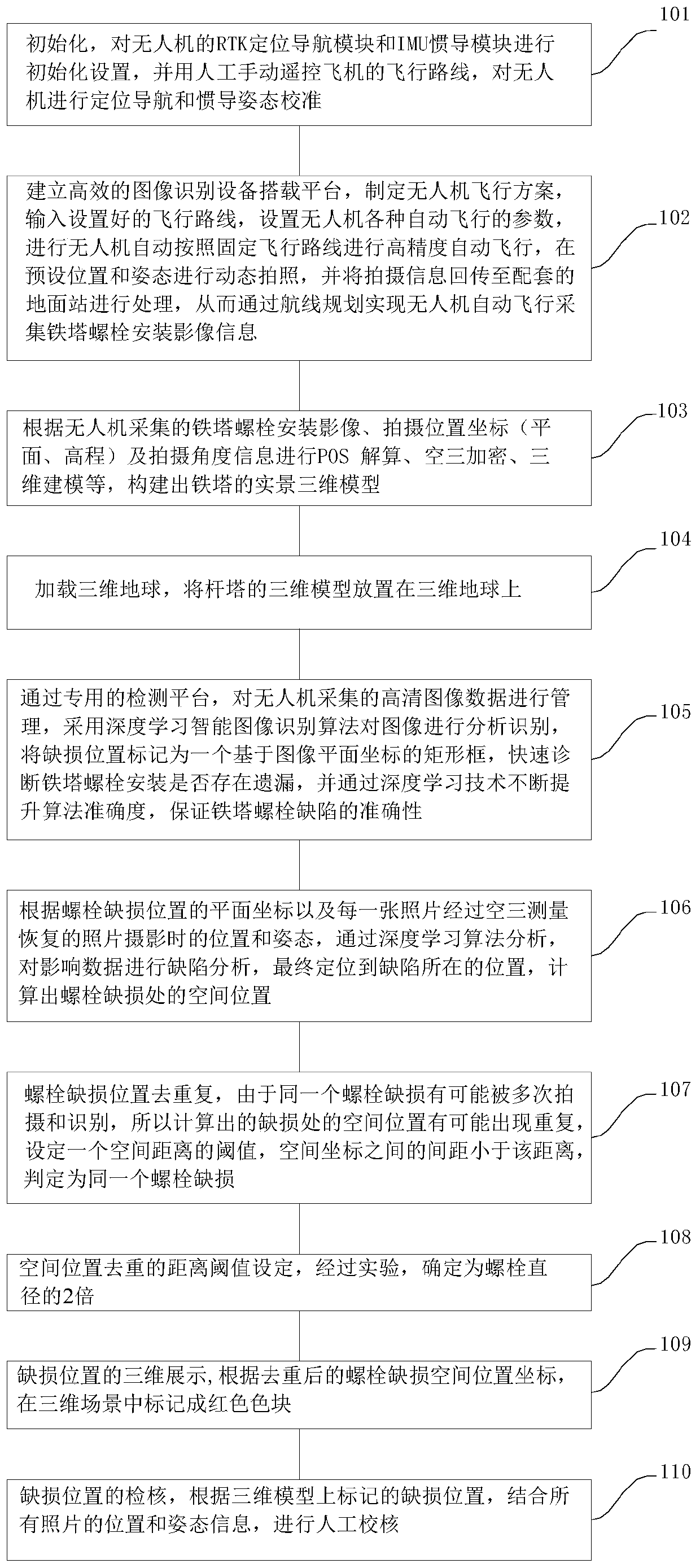

[0043] A method for displaying defects of iron tower bolts based on a 3D real scene model, such as figure 1 , whose characteristics can then include the following steps:

[0044]Step 101, initialization, the RTK (Real Time Kinematic real-time dynamic differential measurement) positioning navigation module and the IMU (Inertial Measurement Unit) inertial navigation module of the unmanned aerial vehicle are initialized, and the flight route of the manual remote control aircraft is used to control the unmanned aerial vehicle. Carry out positioning navigation and inertial navigation attitude calibration;

[0045] Step 102, establish an efficient image recognition equipment platform, formulate a flight plan for the UAV, input the set flight route, set various automatic flight parameters of the UAV, and perform high-precision automatic fli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com