Plate curtain wall assembling and connecting assembly

A curtain wall and installation technology, which is applied in the field of panel curtain wall installation components, can solve the problems of increasing the safety factor of the curtain wall, loose bolts, cracking and falling off of the panel curtain wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

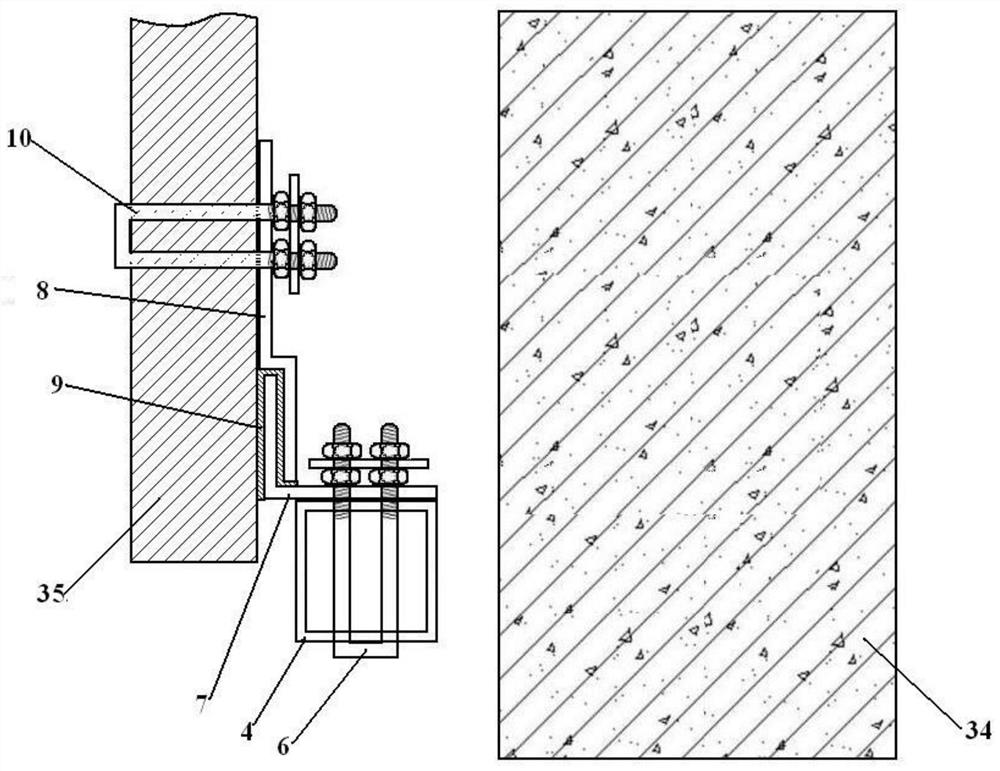

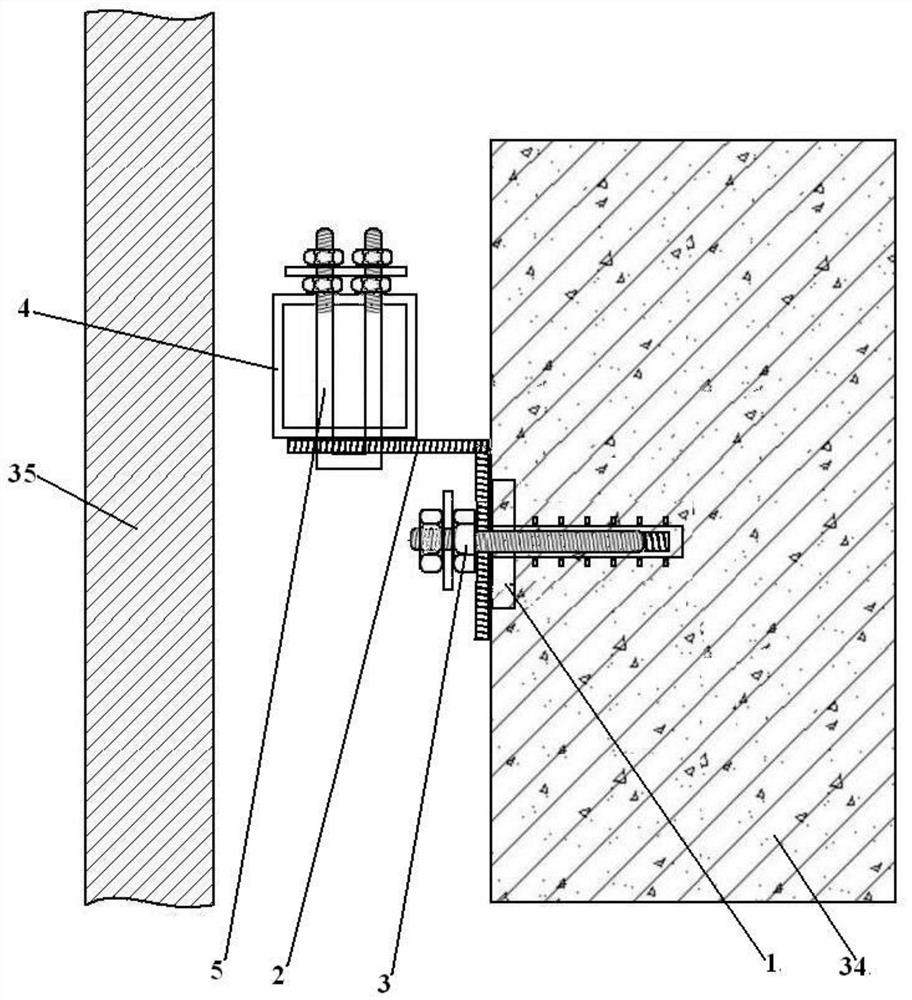

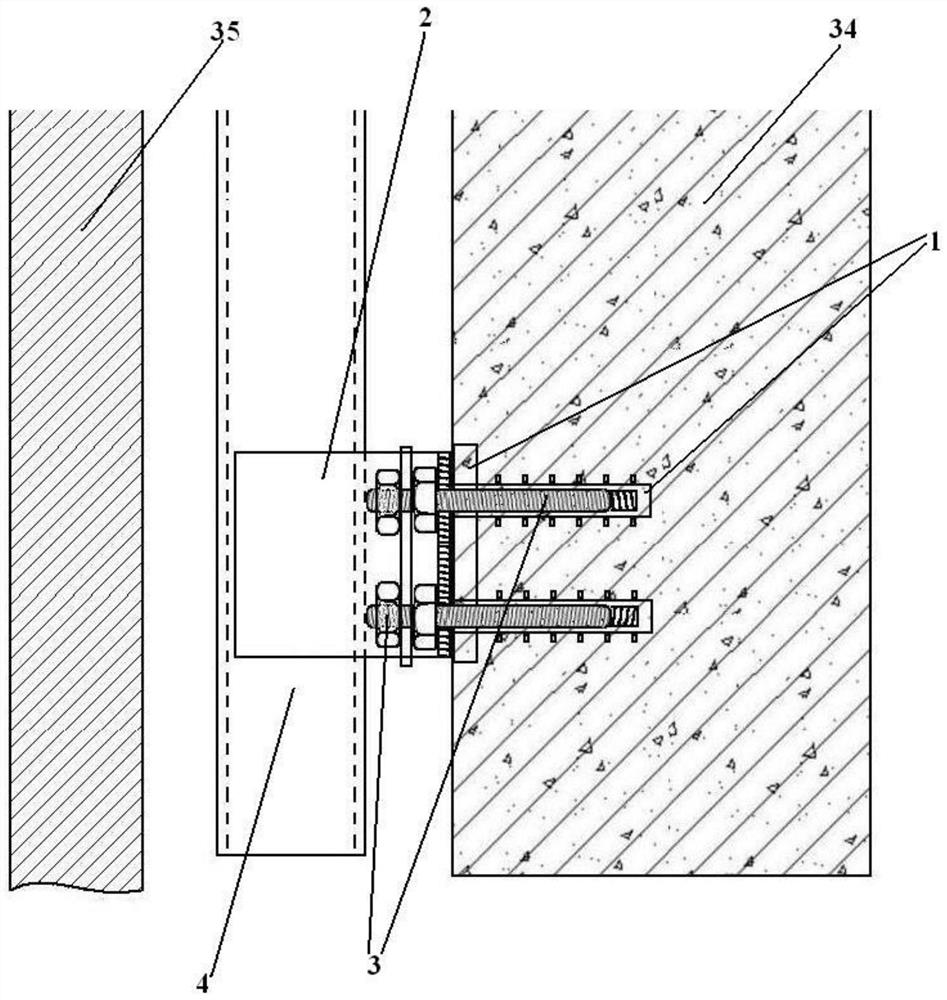

[0052] As shown in the figure, a panel curtain wall assembly is produced, including double-hole anti-rotation anchor 1, angle steel plate 2, anti-rotation bolt assembly 3, square steel keel 4, first square screw assembly 5, The second square-shaped screw assembly 6, right-angle plate 7, zig-zag right-angle plate 8, a few-shaped rubber pad 9 and the third square-shaped screw assembly 10.

[0053] The double-hole anti-rotation anchor 1 includes a panel 11 and two helical tubes 12, the panel 11 is provided with two holes, the inner wall of the helical tube 12 is provided with internal threads, and the inner walls of the two helical tubes 12 The thread direction is opposite, and the two helical tubes 12 are vertically and fixedly installed on the two holes of the panel 11 to form a double-hole anti-rotation anchor 1 .

[0054] The angle steel plate 2 is a right-angle steel plate, and the two straight plates constituting the angle steel plate are respectively called the A straight ...

Embodiment 2

[0073] As shown in the figure, in Embodiment 1, installing the screw 21 in the third screw assembly 10 from the outside of the curtain wall plate 35 will affect the appearance. When the thickness of the curtain wall 35 is sufficient, the third screw may not be used. Shaped screw assembly 10, and anti-rotation screw assembly 36 is used.

[0074] The anti-rotation screw assembly 36 includes two double-ended anti-rotation screws 37, two nuts 16 and a pressing piece 17, and the double-ended anti-rotation screw 37 successively includes a directly connected screw rod 38, a nut 19 and a stud Rod 39, the screw direction of the external thread on the screw rod 38 and the stud rod 39 is opposite; The external threads on the post rod 39 are opposite in direction; the external threads on the stud rod 39 are matched with the internal threads in the nut 16; through holes.

[0075] That is, step ⑺ in Embodiment 1 is constructed according to the following method: drill two blind holes at th...

Embodiment 3

[0077] As shown in the figure, during integral construction, the curtain wall panel 35 below can be installed on the same second screw assembly 6, that is, on the basis of Embodiment 1 or 2, the second screw assembly 6 is also equipped with a lower right-angle plate 7, and the above-mentioned part (5) can be constructed according to the following method: the D straight plate 26 of the right-angle plate 2 is installed on the upper and lower sides of the position staggered with the angle plate 2 on the square steel keel 4, first on the Drill two through holes at the installation position of the square steel keel 4, then align the two through holes on the D straight plate 26 of the first right-angle plate with the two through holes on the upper side of the square steel keel 4, and make the first right-angle plate The vertical direction of the C straight plate 25 is upward, and then the two through holes on the D straight plate 26 of the second right angle plate are aligned with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com