Preparation method of metal matrix amorphous coating

A metal matrix, amorphous coating technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of low density, low amorphous content, poor comprehensive anti-corrosion and wear-resistant performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

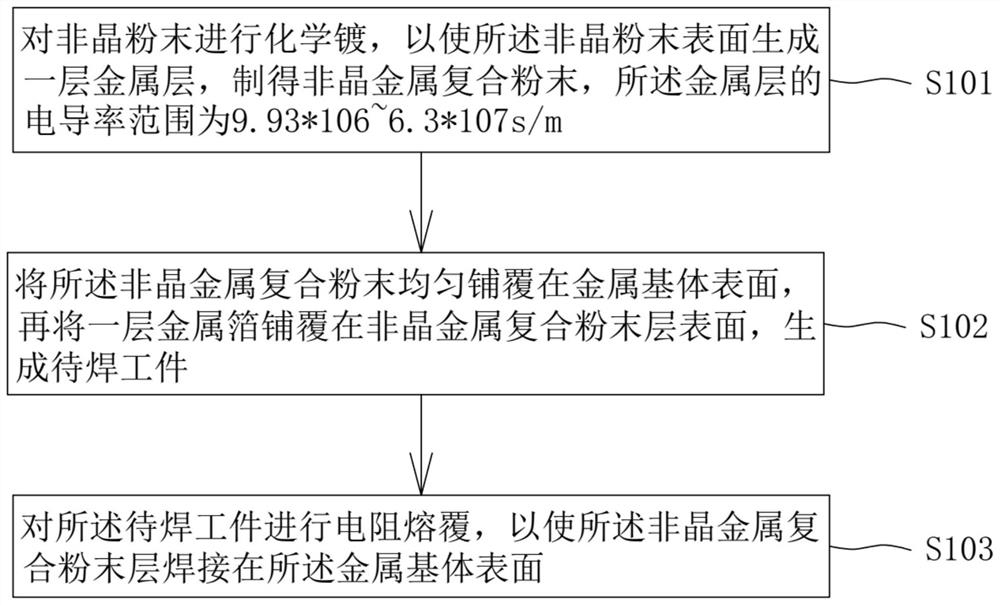

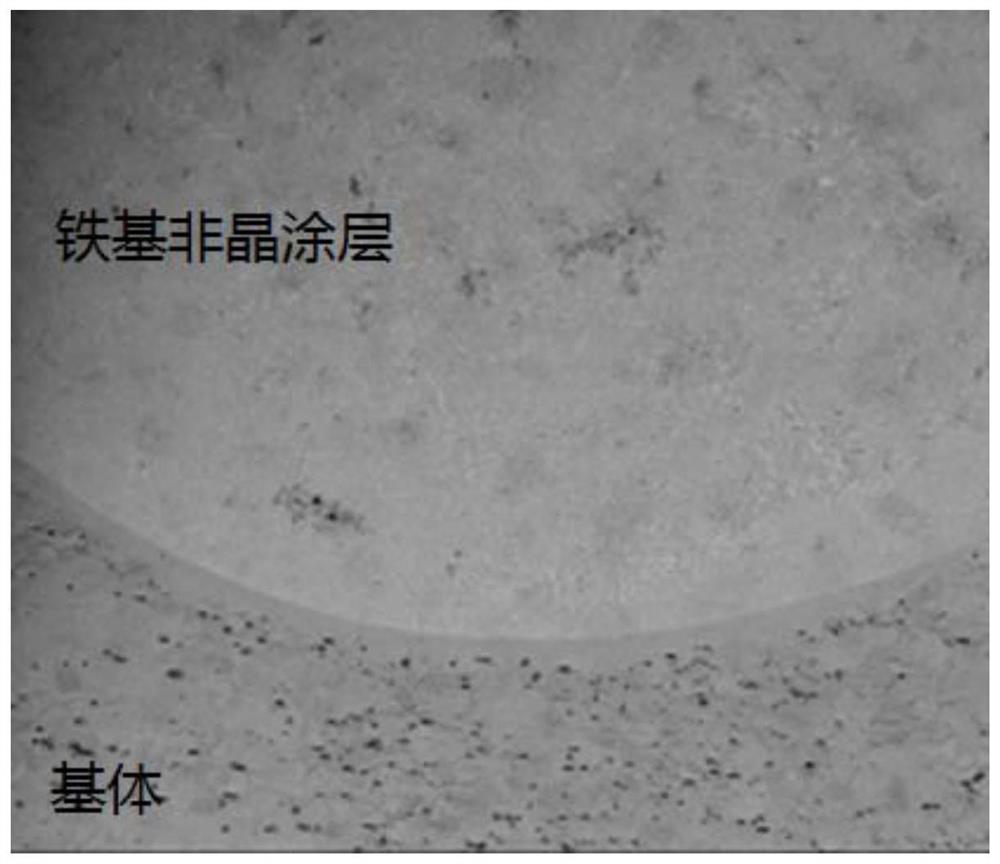

[0037] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a method for preparing an amorphous coating on a metal substrate, including steps S101 to S103:

[0038] S101: Electroless plating is performed on the amorphous powder, and a metal layer is formed on the surface of the amorphous powder after electroless plating to prepare an amorphous metal composite powder, and the conductivity range of the metal layer is 9.93*10 6 ~6.3*10 7 s / m.

[0039] Wherein, the amorphous powder can be amorphous powder of different series and models, the shape is not limited, and the particle size is 10-100 μm.

[0040] The metal layer can be iron, cobalt, chromium, etc., and the corresponding resistivity of the metal layer is 1.65*10 -8 ~9.78*10 -8 (Ω·m), which is a high conductivity material.

[0041] The amorphous powder is subjected to electroless plating so that a metal layer is formed on the surface of the amorphous powder to obtain an amorphous me...

Embodiment 2

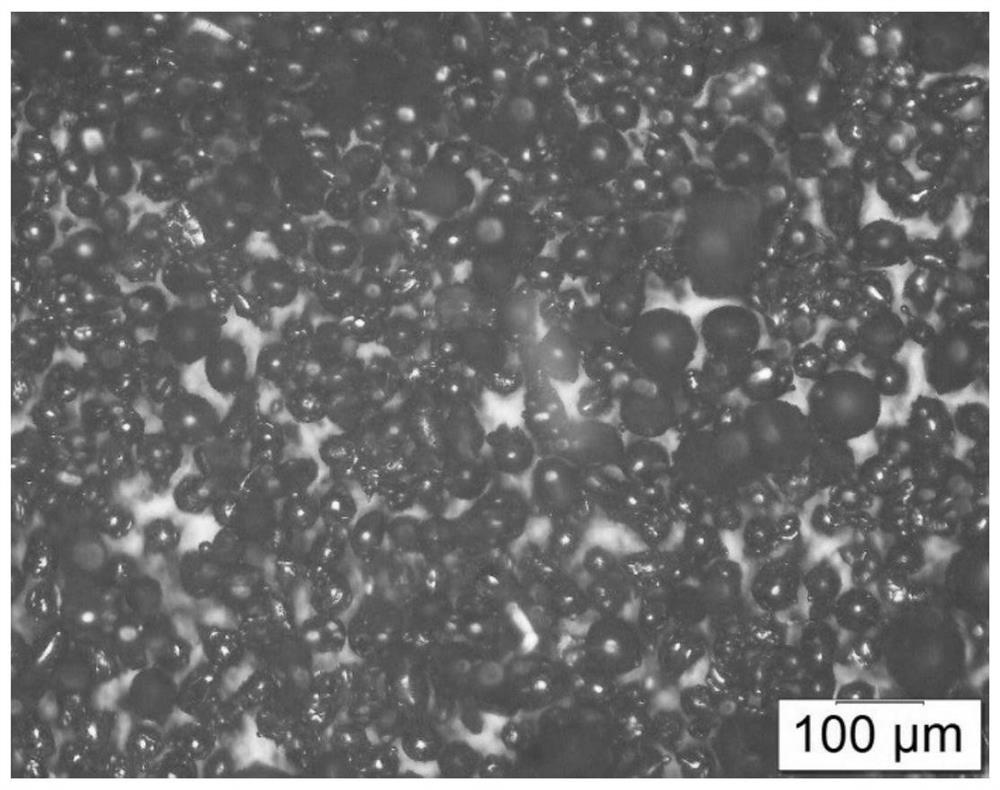

[0066] Prepare Fe-based amorphous powder on the surface of 304 stainless steel. The composition of the obtained amorphous powder is Fe-Co-Cr-Mo-C-B-Y, the particle size is about 50 μm, and it is spherical powder. The plating solution is copper sulfate solution.

[0067] First, put 300-400 mesh Fe-based amorphous powder into NaOH solution to degrease and then fish out, then pour the prepared sensitizing solution into the Fe-based amorphous powder after degreasing treatment, stir thoroughly for 30 minutes, and wait for the powder After complete settling, filter and dry to obtain sensitized Fe-based amorphous powder.

[0068] Pour the prepared activation solution into the sensitized Fe-based amorphous powder, stir thoroughly for 10 minutes, filter after the powder has completely settled, and wash with distilled water for 3 times after filtration to obtain the activated Fe-based amorphous powder. Choose 2g / L AgNO3 solution.

[0069] Pour the activated Fe-based amorphous powder in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com