Iron-based amorphous coating and preparation method thereof

An iron-based amorphous and coating technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problem of large porosity, low amorphous content of iron-based amorphous coating, and poor coating quality. Advanced problems, to achieve the effect of high bonding strength and cohesive strength, high cohesive strength, and dense tissue structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The 60-150 mesh industrial alloy powder ferrochromium, ferromolybdenum, ferroboron, ferrosilicon, and aluminum powder are based on the mass percentage of elements: 23% Cr, 5% Mo, 5% Al, 2% B, 2% Si, and the balance Fe , and weigh the ingredients.

[0060] The mixed powder after batching is put into a mixer and mixed for 2 hours, after mixing evenly, it is dried and kept warm to obtain a powder core powder.

[0061] Select 12×0.3mm (12mm wide, 0.3mm thick) 304 stainless steel strip, first roll it out of the U-shaped groove, then add the above-mentioned powder core powder into the U-shaped groove according to the filling rate of 37%, and put the U-shaped The groove is closed, and the diameter is reduced to the required diameter of 2 mm by wire drawing to make a powder core wire.

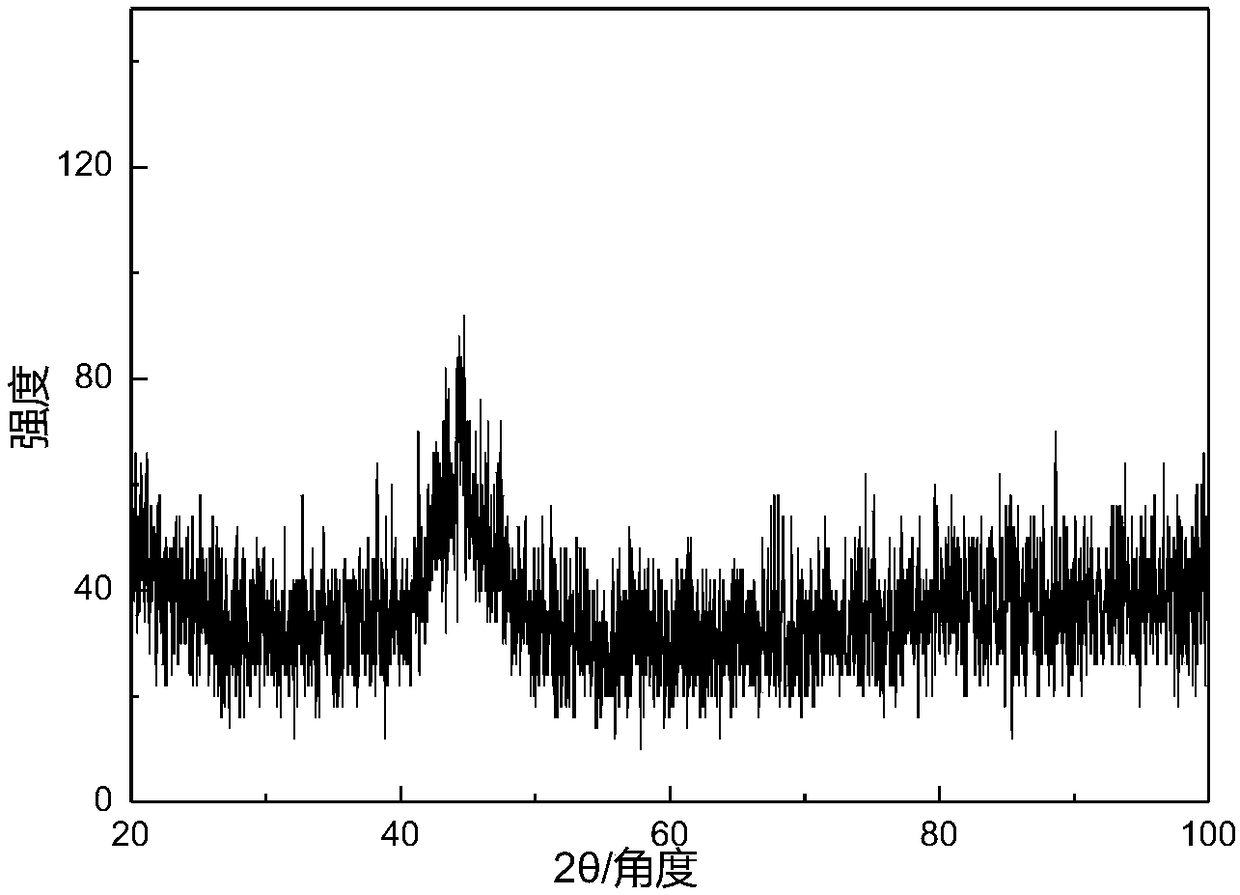

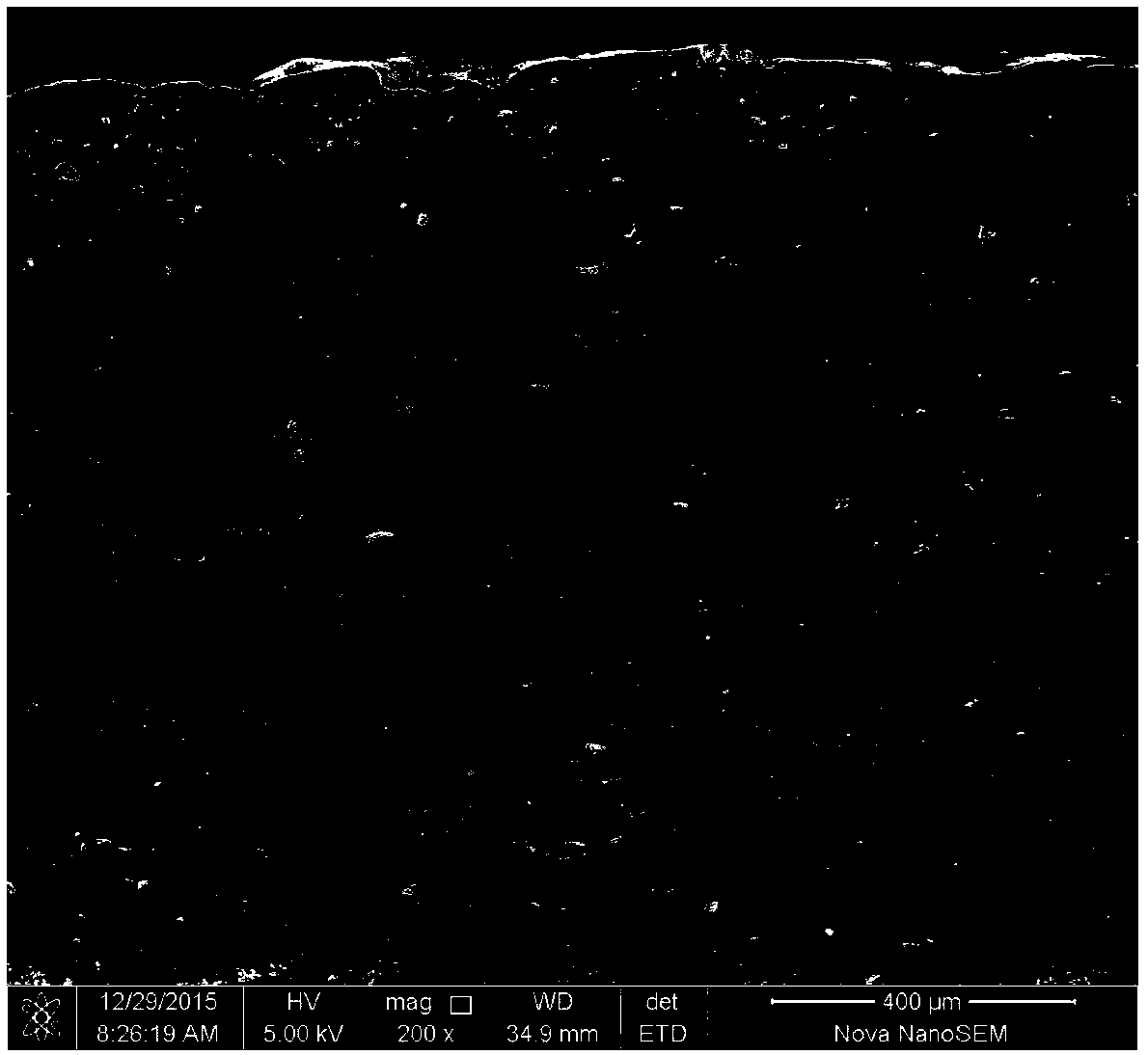

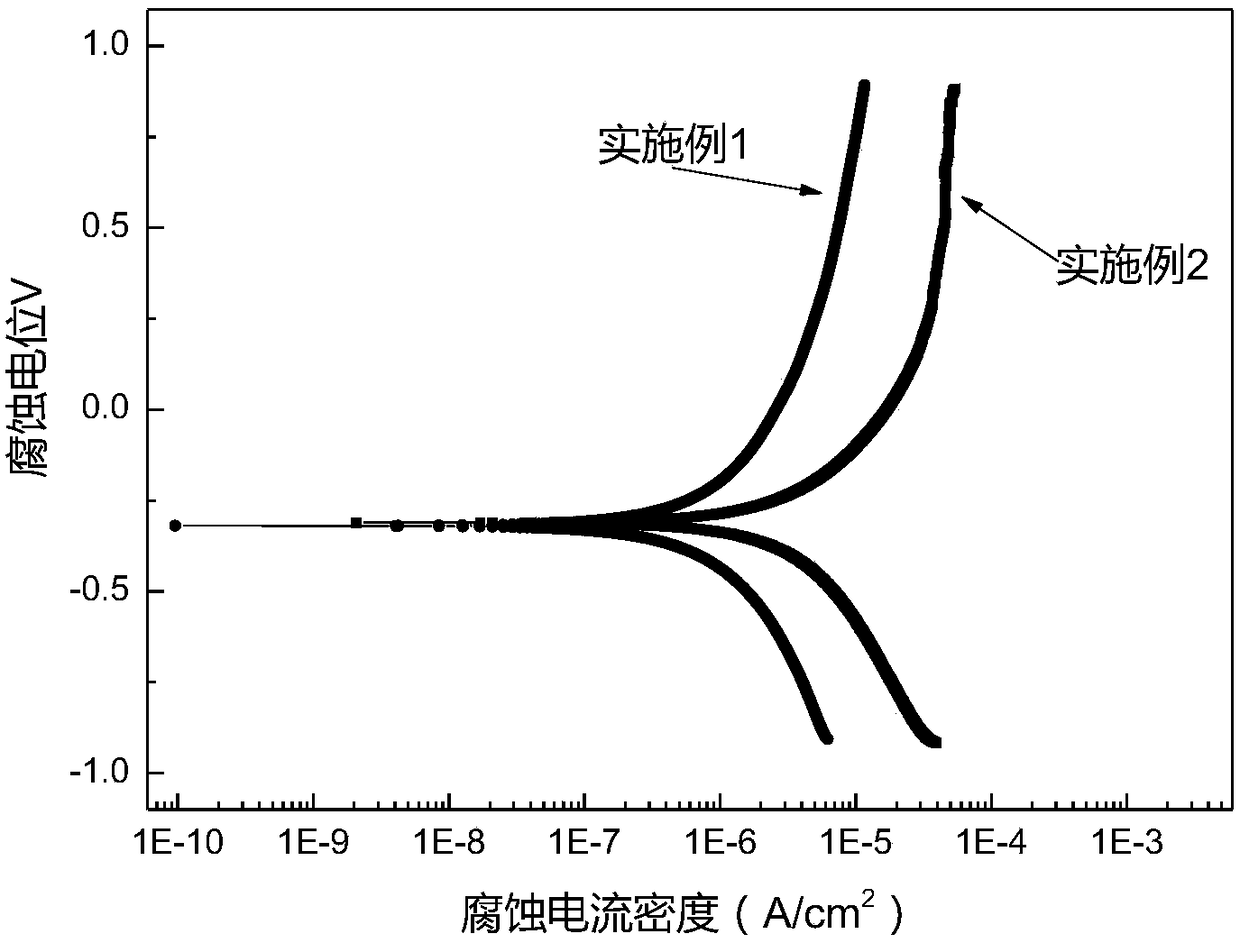

[0062] Using the powder core wire material prepared above, after degreasing, derusting, sandblasting and roughening at 45 # The arc spray coating was prepared on the steel substrate, the spray...

Embodiment 2

[0066] The 60-150 mesh industrial alloy powder ferrochromium, ferromolybdenum, ferroboron, ferrosilicon, and aluminum powder are based on the mass percentage of elements: 15% Cr, 10% Mo, 5% Al, 5% B, 5% Si, and the balance Fe , and weigh the ingredients.

[0067] The mixed powder after batching is put into a mixer and mixed for 2 hours, after mixing evenly, it is dried and kept warm to obtain a powder core powder.

[0068] Choose a 12×0.3mm (12mm wide, 0.3mm thick) ordinary carbon steel strip, first roll out a U-shaped groove, then add the above-mentioned powder core powder into the U-shaped groove according to the filling rate of 40%, and put the U-shaped The shape groove is closed, and the diameter is reduced to the required diameter of 2 mm through wire drawing to make the powder core wire.

[0069] Using the powder core wire material prepared above, after degreasing, derusting, sandblasting and roughening at 45 # The arc spray coating was prepared on the steel substrate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com