Aluminum alloy amorphous powder material, preparation method, application and coating preparation method

An amorphous powder and powder material technology, which is applied in the fields of preparation, coating preparation, and aluminum alloy amorphous powder materials, can solve the problem that Al-based amorphous powder is difficult to prepare in large quantities, the production cost of Al-based amorphous powder is high, and the industrial application There are few problems such as exploration and research to achieve the effect of improving aircraft survivability, improving comprehensive anti-fatigue performance, and being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

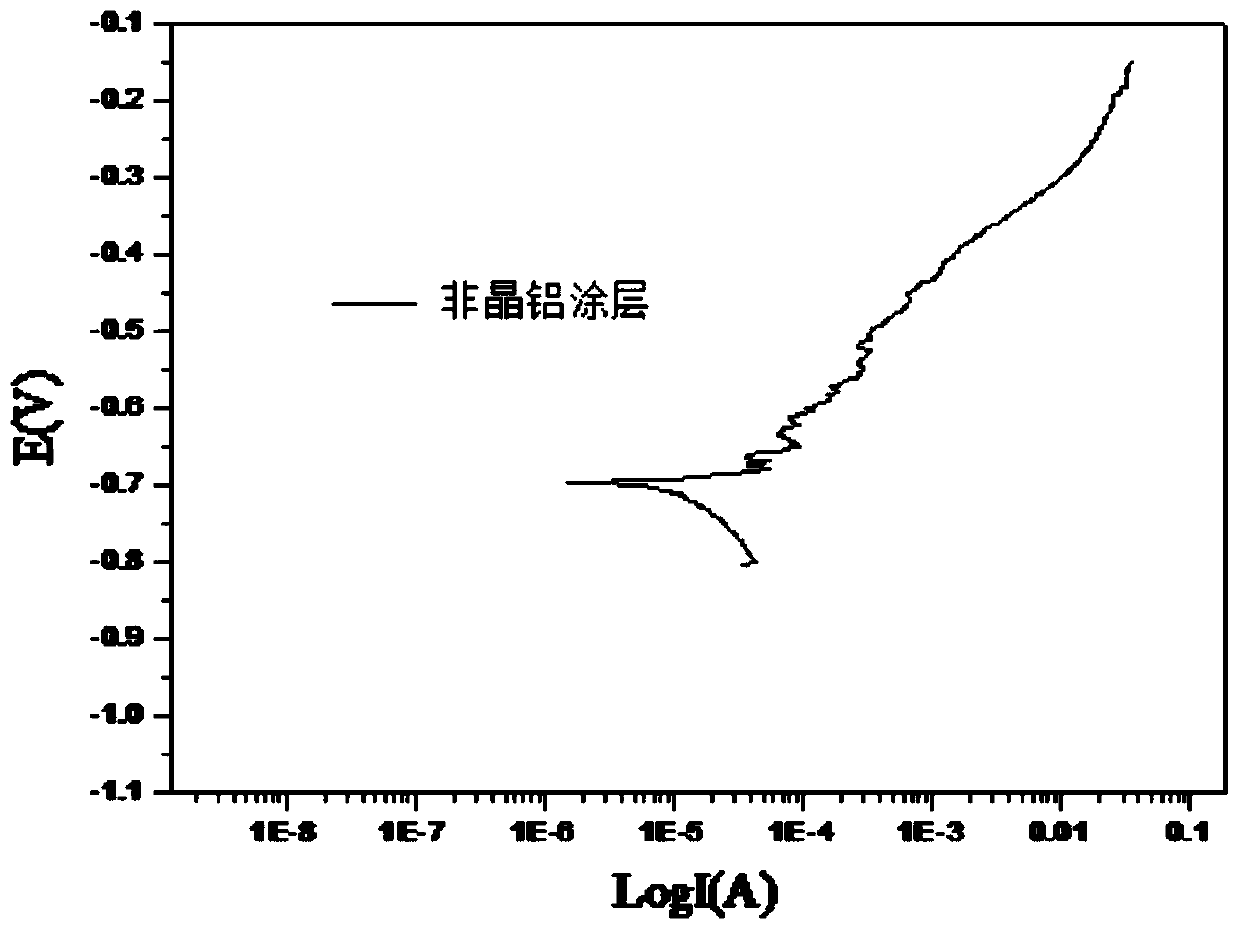

[0040] This embodiment relates to the anti-corrosion, wear-resistant and anti-fatigue aluminum alloy amorphous powder material, coating preparation method and application in the aviation field of the present invention.

[0041] (1) The composition of the alloy elements is configured according to the atomic percentage: 84% Al, and the rest are Ni, La, Co, Y, and Gd.

[0042] (2) Open the argon gas valve, conduct atomization at a melting temperature of 1200° C. and an atomization pressure of 38 kg to prepare an amorphous powder.

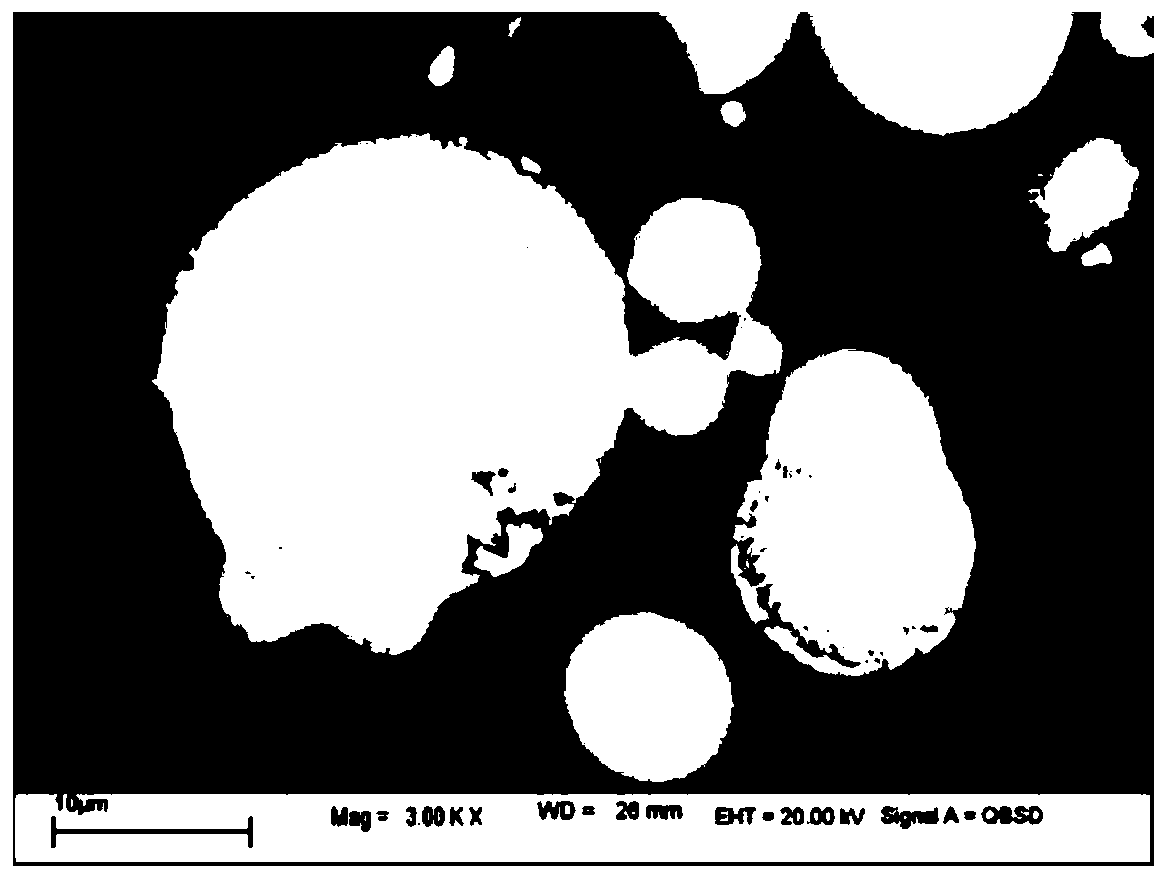

[0043] (3) After cooling the atomized aluminum alloy powder, remove the powder collector and sieve to obtain a powder with a particle size distribution of 10-30 μm.

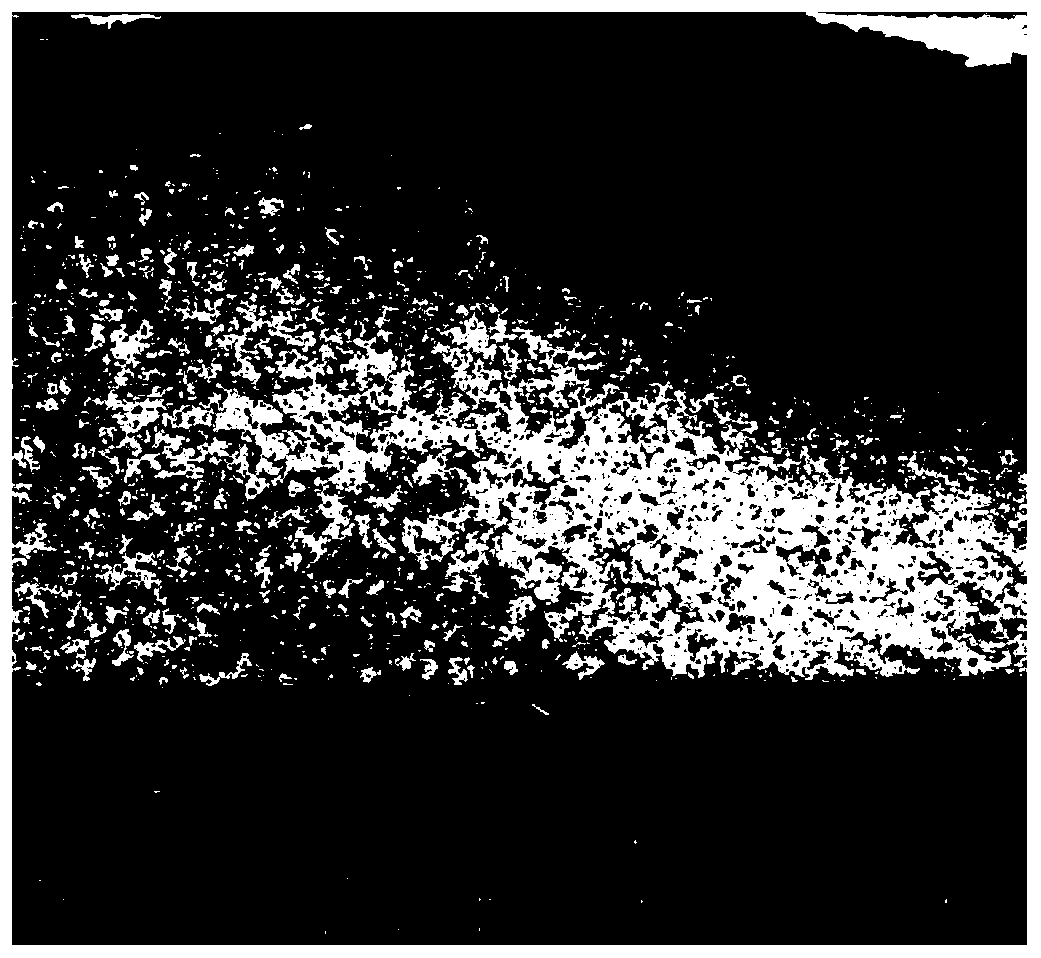

[0044] (4) The obtained aluminum alloy amorphous powder is sprayed on the surface of the light alloy member by cold spraying process, and the spraying process parameters are as follows: carrier gas nitrogen preheating temperature 320°C, pressure 2.5MPa, spraying distance 12mm;

[0045] (...

Embodiment 2

[0047] This embodiment relates to the anti-corrosion, wear-resistant and anti-fatigue aluminum alloy amorphous powder material, coating preparation method and application in the aviation field of the present invention.

[0048] (1) The composition of the alloy elements is configured according to the atomic percentage: 86% Al, and the rest are Ni, La, Co, Y, and Gd.

[0049] (2) Open the argon gas valve, conduct atomization at a melting temperature of 1250° C. and an atomization pressure of 30 kg to prepare amorphous powder.

[0050] (3) After cooling the atomized aluminum alloy powder, remove the powder collector and sieve to obtain a powder with a particle size distribution of 10-30 μm.

[0051] (4) The obtained aluminum alloy amorphous powder is sprayed on the surface of the light alloy member by cold spraying process, and the spraying process parameters are as follows: carrier gas nitrogen preheating temperature is 380°C, pressure is 2.5MPa, and spraying distance is 15mm; ...

Embodiment 3

[0054] This embodiment relates to the anti-corrosion, wear-resistant and anti-fatigue aluminum alloy amorphous powder material, coating preparation method and application in the aviation field of the present invention.

[0055] (1) The composition of the alloy elements is arranged according to the atomic percentage: 88% Al, and the rest are Ni, La, Co, Y, and Gd.

[0056] (2) Open the argon gas valve, atomize and prepare amorphous powder at a melting temperature of 1300° C. and an atomizing pressure of 30 kg.

[0057] (3) After cooling the atomized aluminum alloy powder, remove the powder collector and sieve to obtain a powder with a particle size distribution of 10-30 μm.

[0058] (4) The obtained aluminum alloy amorphous powder is sprayed on the surface of the light alloy member by cold spraying process, and the spraying process parameters are as follows: carrier gas nitrogen preheating temperature is 410°C, pressure is 2.8MPa, and spraying distance is 20mm;

[0059] (5) Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com