Amorphous coating preparation method based on laser cladding and pulsed electron beam irradiation

A technology of pulsed electron beam and laser cladding, which is applied in coating, metal material coating process, etc., to achieve the effect of avoiding coating oxidation, improving hardness and wear resistance, and enriching deformation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First dry the zirconium powder with a particle size of 200 mesh in a vacuum environment at 50°C for 12 h, then weigh 75.87 g of Zr powder, 11.37 g of Ni powder, 3.79 g of Al powder, and 8.94 g of Cu powder with a particle size of 200 mesh, and add them into a ball mill and mix them for 2 h to obtain the powder for laser cladding. Mix powder. A 702 zirconium block sample with a size of 20×20×10 mm was taken, and the surface was roughly ground with 180-mesh metallographic sandpaper, then cleaned with acetone to remove oil stains, wiped clean, then wiped with alcohol, and dried to obtain a preliminary sample. Treated zirconium alloy matrix material.

[0034] The surface-treated zirconium alloy samples were placed on the laser cladding workbench for use, and argon was used as the shielding gas.

[0035] Using the laser cladding method of pre-set powder, the mixed alloy powder is pre-laid on the surface of the substrate, and the laser cladding process parameters are adjuste...

Embodiment 2

[0043] Taking the matrix and powder in Example 1, adjust the laser cladding process parameters as follows: laser power 1200W, spot diameter 4mm, scan speed 5mm / s. Under laser energy irradiation, a coating that is metallurgically bonded to the substrate is formed on the surface of the zirconium alloy.

[0044] The pulsed electron beam treatment was performed on the coating after cladding, and the parameters of the pulsed electron beam were the same as those in Example 1.

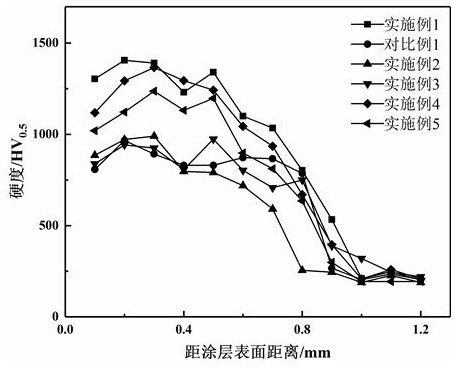

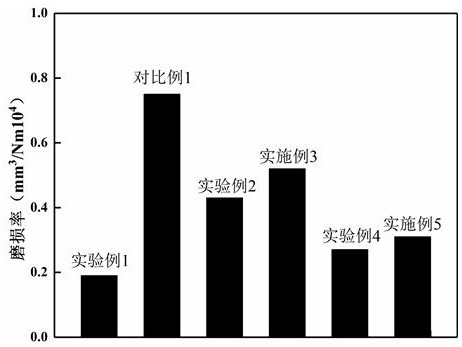

[0045] According to the test method of Example 1, the hardness and wear resistance of the cladding layer were detected. Hardness curve such as figure 1 As shown, the wear rate results are as figure 2 shown.

Embodiment 3

[0047] Taking the matrix and powder in Example 1, adjust the laser cladding process parameters as follows: laser power 2500W, spot diameter 4mm, scanning speed 5mm / s. Under laser energy irradiation, a coating that is metallurgically bonded to the substrate is formed on the surface of the zirconium alloy.

[0048] The pulsed electron beam treatment was performed on the coating after cladding, and the parameters of the pulsed electron beam were the same as those in Example 1.

[0049] According to the test method of Example 1, the hardness and wear resistance of the cladding layer were detected. Hardness curve such as figure 1 As shown, the wear rate results are as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com