Preparation method of amorphous coating on metal substrate

A metal matrix, amorphous coating technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of poor anti-corrosion and wear-resistant comprehensive performance, low bonding strength, low compactness, etc. The effect of less coating defects, low cost, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

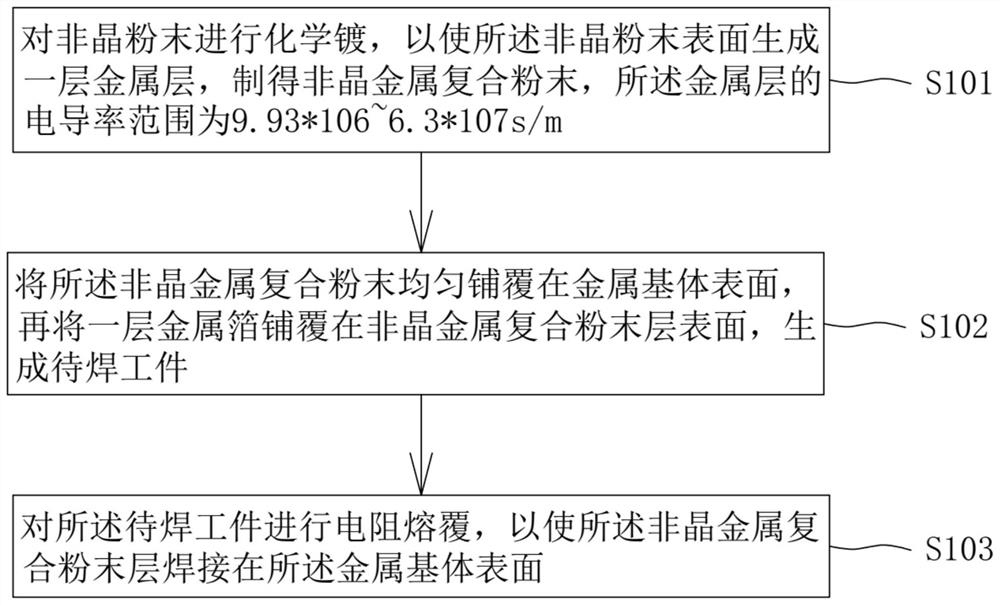

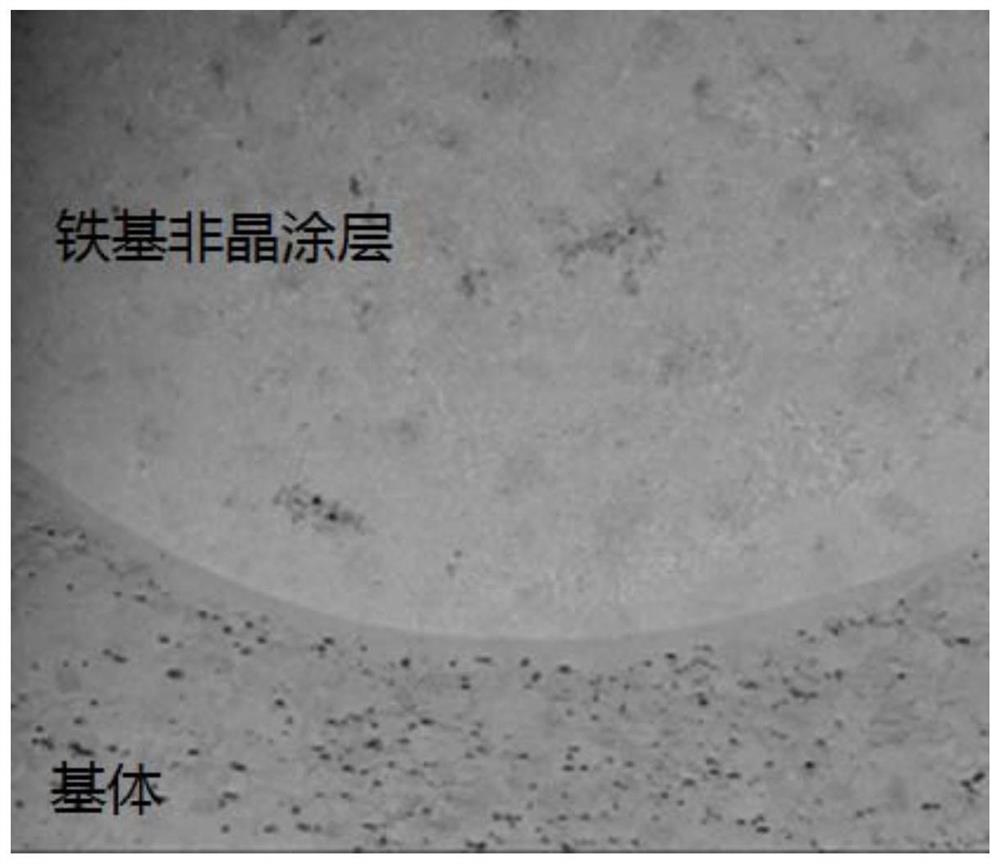

[0037] like Figure 1 to 5 As shown, embodiments of the present invention provide a method of preparing a metal matrix amorphous coating, including steps S101 to S103:

[0038] S101: Chemical plating of amorphous powders, forming a layer of metal layer after chemically plating, producing an amorphous metal composite powder, the electrical conductivity of the metal layer is 9.93 * 10 6 ~ 6.3 * 10 7 S / m.

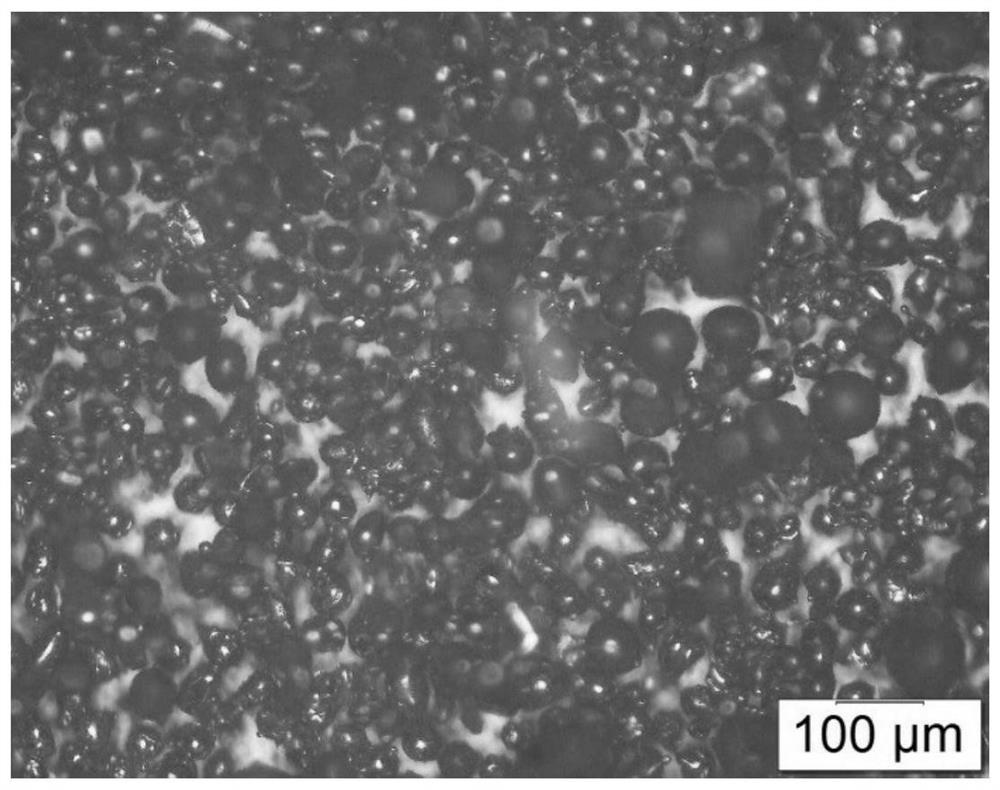

[0039] Among them, the amorphous powder can be a different series of amorphous powders, the shape is not limited, and the particle size is 10 to 100 μm.

[0040] The metal layer can take iron, cobalt, chromium, and the like, and the electrical resistivity corresponding to 1.65 * 10 -8 ~ 9.78 * 10 -8 (Ω · m), for high conductivity material.

[0041] The amorphous powder is chemically plated such that the amorphous powder surface forms a layer of metal layer, and the non-alcoholic metal composite powder is prepared, and the electrical conductivity range of the metal layer is 9.93 *...

Embodiment 2

[0066] FE-CO-CR-MO-C-B-Y is prepared at 304 stainless steel surface, and the obtained amorphous powder component is FE-Co-Cr-Mo-C-B-Y, the particle size is 50 μm, which is a spherical powder, and the plating solution is a copper sulfate solution.

[0067] First, 300 to 400 destination FE-based non-crystalline powders were placed in the NaOH solution and then removed, and then poured into the FE-based amorphous powder of the formulated sensitization into the oil, stirred for 30 min, to be powder After completely settlement, filtered, dried, and the FE-based amorphous powder was obtained.

[0068] The formulated activated liquid is poured into the sensitized Fe group, stirred for 10 min, and filtered after the powder is completely settled. After filtering with distilled water, it is activated to activate the FE-based amorphous powder, activating liquid Choose 2g / L AGNO3 solution.

[0069] The activated FE-based amorphous powder was poured into a copper sulfate solution, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com