Super-amphiphobic acid-resistant coating and preparation method thereof

An acid-resistant coating and super-amphiphobic technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of high preparation cost, complicated preparation process, and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a super amphiphobic acid-resistant coating, comprising the following steps:

[0029] Step 1, modified nano-SiO 2 Particle preparation

[0030] nano-SiO 2 The particles were immersed in an ethanol solution of fluorosilane for modification at room temperature, and the modified nano-SiO 2 After the particles are dried, grind and disperse;

[0031] Step 2, preparation of super amphiphobic acid-resistant coating

[0032] Apply the polyurethane anti-corrosion coating on the surface of the pretreated substrate and dry it. After the coating on the surface of the substrate enters a semi-cured state, use a pneumatic powder spray gun to spray the modified nano-SiO 2 The particles are sprayed on the surface of the semi-cured coating and cured to obtain a super-amphiphobic acid-resistant coating.

[0033] The fluorosilane in the fluorosilane-absolute ethanol modification solution is trimethoxy (1H, 1H, 2H, 2H-heptadecafluorodecyl) s...

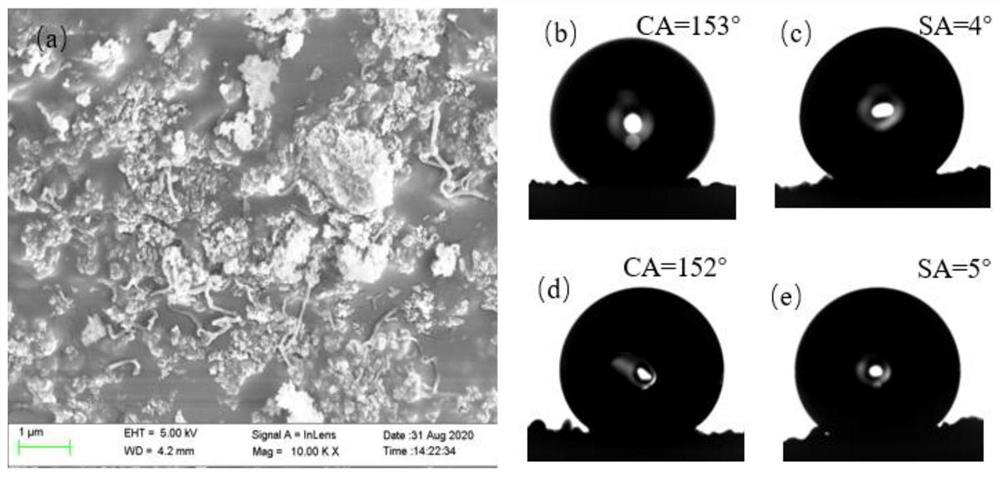

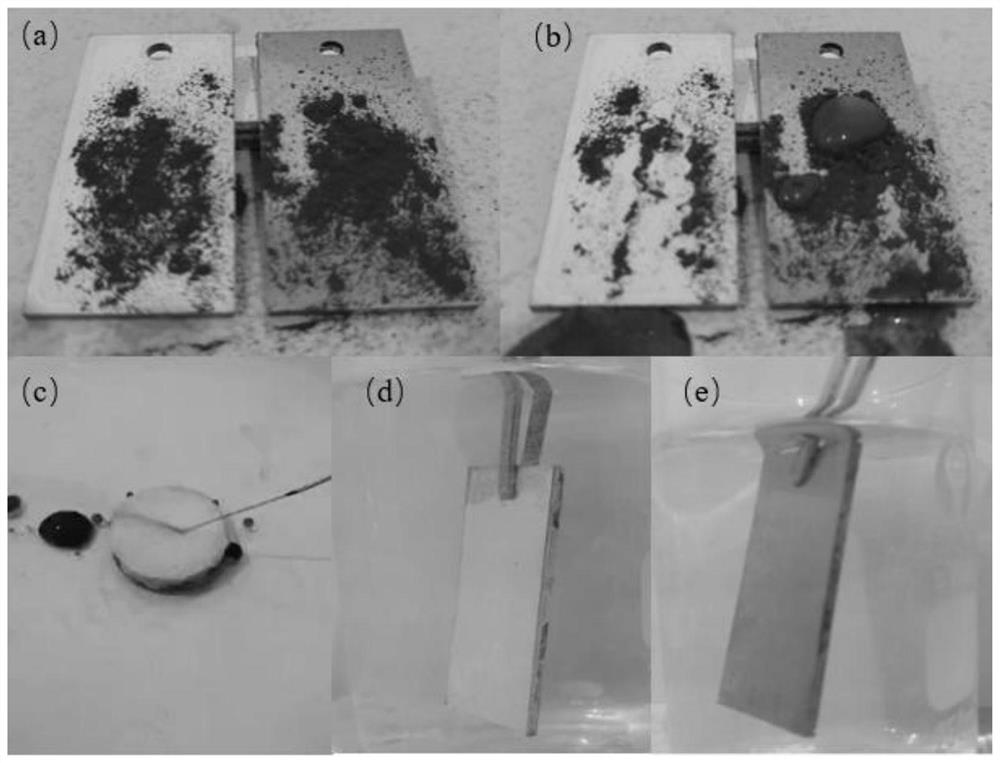

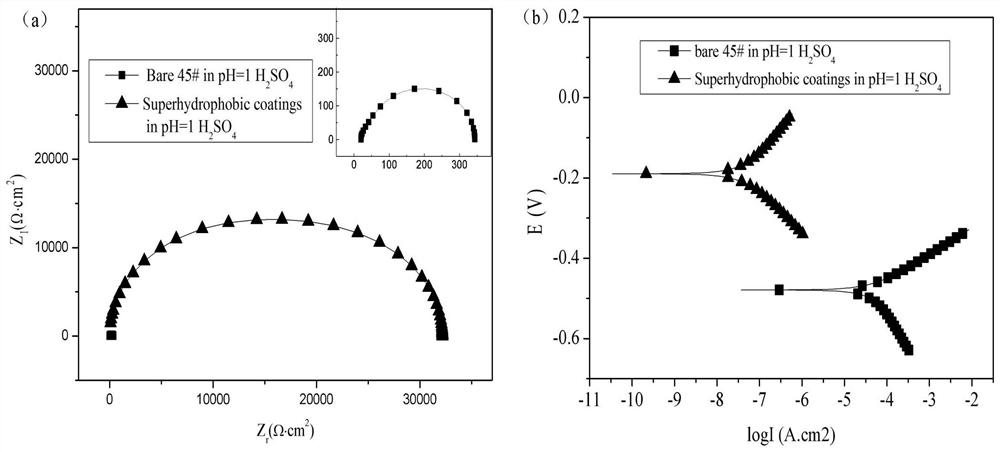

Embodiment 1

[0035] A preparation method for a super amphiphobic acid-resistant coating, comprising the following steps:

[0036] Step 1, modified nano-SiO 2 Particle preparation: 1g of nano-SiO with a particle size of 20nm 2 Particles were immersed in 15g mass fraction of 0.5wt% trimethoxy (1H, 1H, 2H, 2H-tridecafluorodecyl) silane in ethanol solution and modified at room temperature for 0.5h, and the modified nano-SiO 2 The particles were dried at 100°C for 4 hours, and ground and dispersed to obtain modified nano-SiO with a particle size of 30nm. 2 particle;

[0037] Step 2, preparation of two-component anti-corrosion coatings: prepare two-component polyurethane coatings with the main agent and curing agent of Shijiazhuang Kaibo Chemical Co., Ltd. model XDY-J801 according to the volume ratio of 6:1. After stirring evenly, add After mixing, XDY-J104 polyurethane diluent with the same volume as the two-component polyurethane coating, after mixing evenly, the anti-corrosion coating can ...

Embodiment 2

[0041] A preparation method for a super amphiphobic acid-resistant coating, comprising the following steps:

[0042] Step 1, modified nano-SiO 2 Particle preparation: 1g of nano-SiO with a particle size of 30nm 2 Particles were immersed in 25g mass fraction of 1.5wt% trimethoxyl (1H, 1H, 2H, 2H-tridecafluorodecyl) silane ethanol solution for modification at room temperature for 1h, and the modified nano-SiO 2 The particles were dried at 150°C for 5 hours, and ground and dispersed to obtain modified nano-SiO with a particle size of 50nm. 2 particle;

[0043]Step 2, the preparation of two-component anti-corrosion coatings: prepare two-component polyurethane coatings with Shijiazhuang Kaibo Chemical Co., Ltd. model XDY-J801 main agent and curing agent according to the volume ratio of 6:1. The volume ratio of component polyurethane paint and XDY-J104 polyurethane thinner is 1:1.5, add XDY-J104 polyurethane thinner, and mix well to get anti-corrosion coating;

[0044] Step 3, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com