Acridine compounds, polymers and their applications, light-emitting devices

A technology for light-emitting devices and compounds, which is applied in the manufacturing of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve problems such as unfavorable device luminescence, and achieve the effect of improving luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

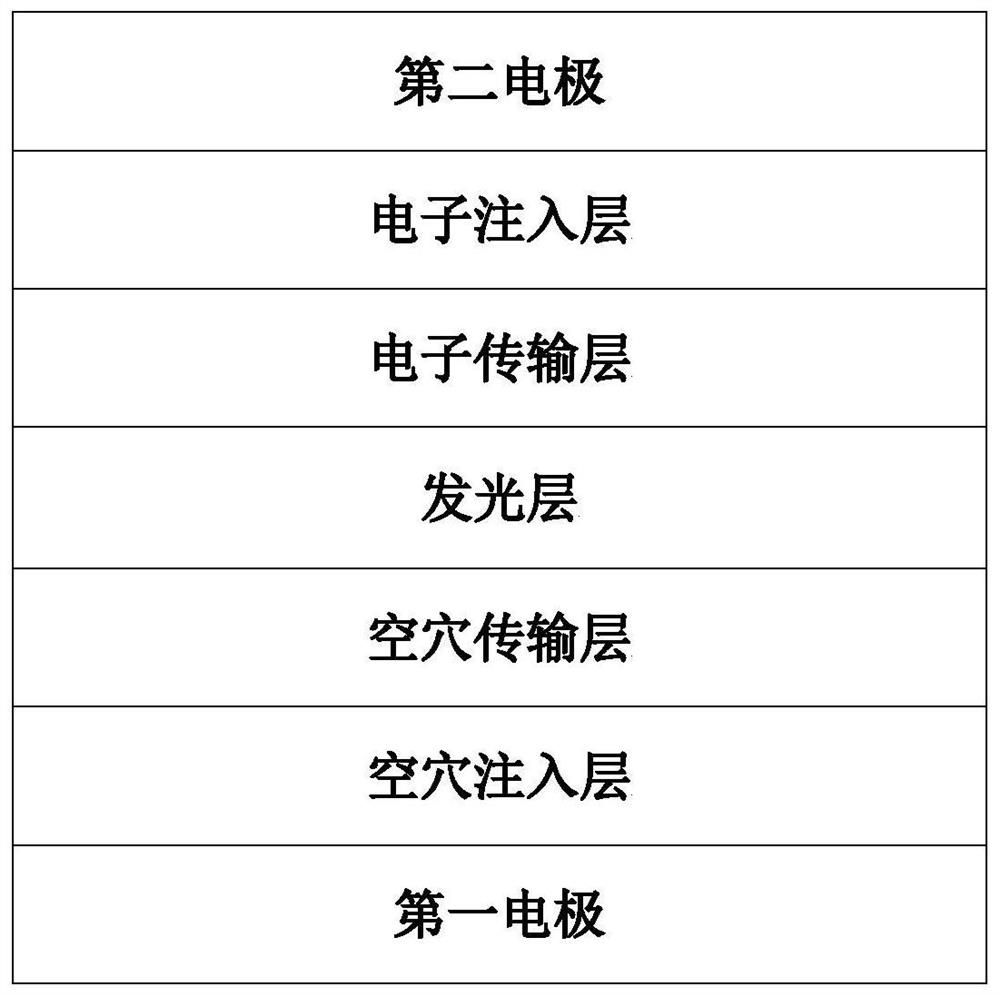

[0098]The preparation method of the light-emitting device comprises the following steps:

[0099] (1) First, clean the ITO substrate in the following order: 5% KOH solution ultrasonication for 15 minutes, pure water ultrasonication for 15 minutes, isopropanol ultrasonication for 15 minutes, and oven drying for 1 hour; then transfer the substrate to UV-OZONE equipment for surface treatment for 15 minutes. Immediately transfer to the glove box.

[0100] (2) Spin-coat a layer of hole injection layer material, namely PEDOT:PSS thin film, on a clean ITO substrate, and then bake at 230° C. for 15 minutes.

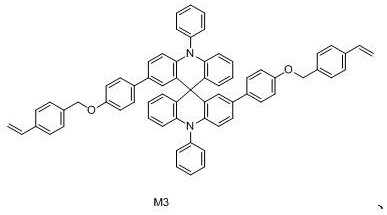

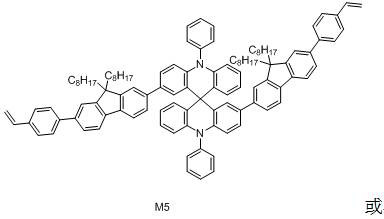

[0101] (3) dissolving the acridine compound (M) in o-xylene to form a solution, spin coating the solution on the hole injection layer film by spin coating, and then baking at 80° C. for 10 min to remove the residual solvent, and then Make it cross-linked at 230°C for 30-60 minutes.

[0102] (5) Spin-coat the luminescent layer ink, and then vapor-deposit the electron transport l...

Embodiment 1~8

[0105] Using compounds M1-M8 as materials for the hole transport layer, light-emitting devices 1-8 were prepared according to the structures and preparation methods of the above-mentioned light-emitting devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com