A kind of coated silicon dioxide microsphere and preparation method thereof

A silica and film-coated technology, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve the problems of cumbersome preparation process, limit the wide application of resin-coated proppant, etc., and achieve improved dispersion. High performance, simple method, and the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

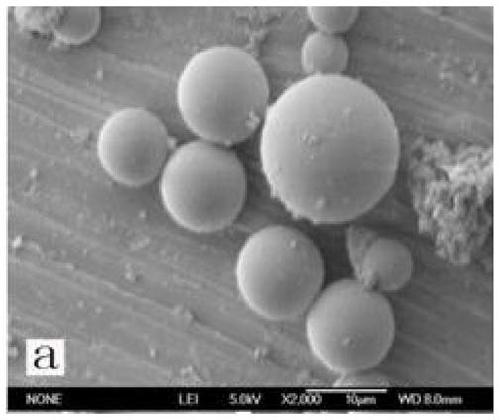

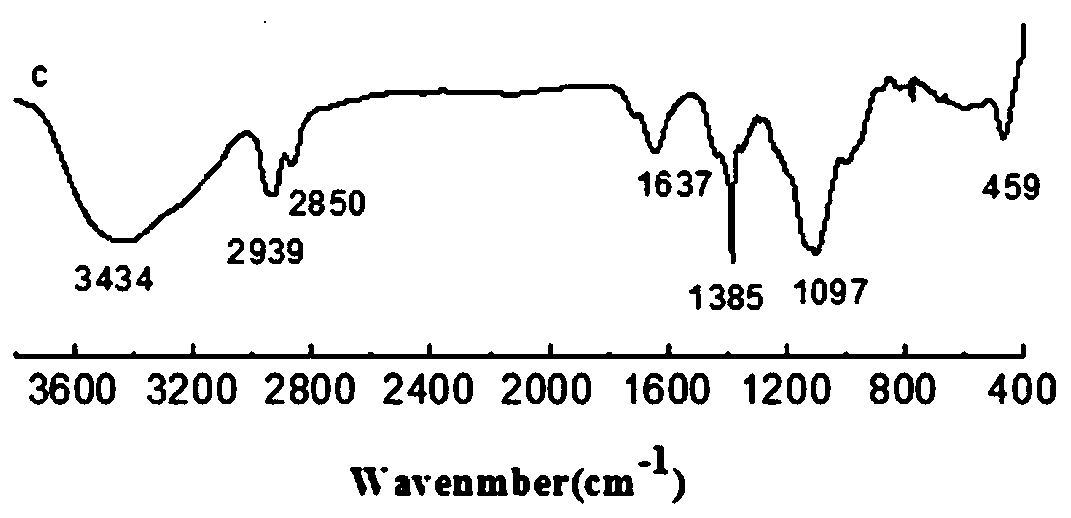

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of coated silica microspheres, comprising the following steps:

[0031] (1) mixing silicon dioxide, hydroxyl compound and water to obtain a mixed material liquid;

[0032] (2) heating up the mixed material liquid obtained in the step (1), and coating the silicon dioxide with the hydroxyl compound in water to obtain coated silicon dioxide;

[0033] (3) mixing the coated silicon dioxide obtained in the step (2) with a dispersant and an emulsifier for dispersion and emulsification to obtain an emulsion;

[0034] (4) under the action of an acidic catalyst, the emulsion obtained in the step (3) is subjected to a cross-linking reaction to obtain coated silica;

[0035] The cross-linking agent for the cross-linking reaction is an aldehyde-based cross-linking agent.

[0036] In the present invention, unless otherwise specified, the raw materials used in the preparation method of the coated silica microspheres are all commercially av...

Embodiment 1

[0053] (1) Put 1.5g of silicon dioxide, 4.0g of polyvinyl alcohol, and 40mL of distilled water in a container with a thermometer, a stirrer and a condenser tube and stir until they are evenly mixed.

[0054] (2) The above container was used as a reaction container, and the reaction temperature was set to 90° C., heated and stirred for 1 hour until the solution became transparent, and the coating process was completed, and then the temperature was lowered to 50° C.

[0055] (3) Add 80mL of liquid paraffin and 2g of span-80 to the coated reaction vessel, and stir rapidly at a speed of 700r / min for 1h using the inverse emulsification method to disperse into a stable emulsion; in order to reduce the particle size distribution of the product , slow down the speed, and continue to emulsify for 30 minutes at a speed of 300r / min.

[0056] (4) After the emulsification is completed, add 7.5g mass concentration of 0.06g / cm 3 Cross-linking agent glutaraldehyde solution and 0.6mL catalyst...

Embodiment 2

[0060] Prepare coated silica microspheres according to the method of Example 1, the difference is that in step (2) the coating process is heated and stirred at 100°C for 0.5h until the solution becomes transparent, the coating process is completed, and then the temperature is lowered to 50°C; Step (3) In the process of dispersing emulsification, emulsify at 750rpm for 1.5h, and at 400rpm for 0.5h; step (4) adjust the amount of glutaraldehyde to 9.5g, and cross-link for 0.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com