Friction riveting device for thermoplastic carbon fiber composite material and aluminum alloy and riveting method of friction riveting device

A technology of composite materials and riveting devices, which can be applied to other household appliances, household components, household appliances, etc., and can solve problems such as connection failure, cracks, and small plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0049] Thermoplastic composites can produce plastic flow effects after being heated to a certain temperature, and restore their original properties after cooling, so the softening flow properties of thermoplastic composites at high temperatures can be used to connect dissimilar materials.

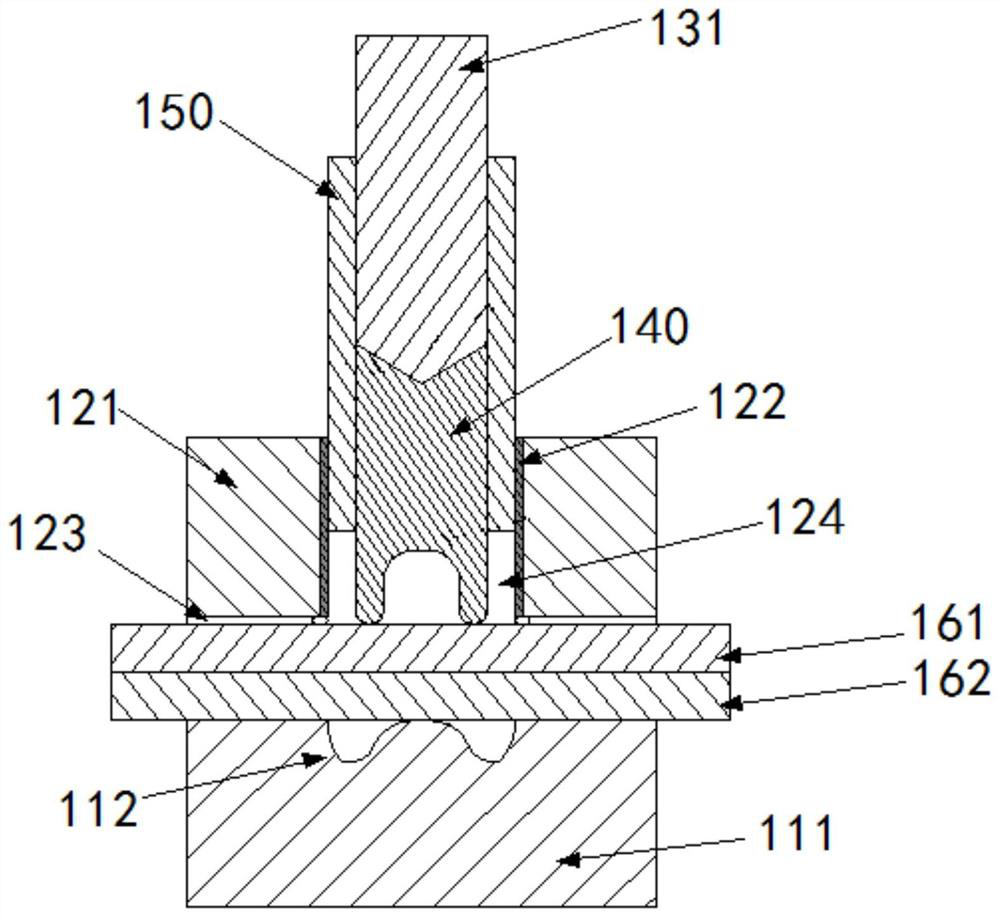

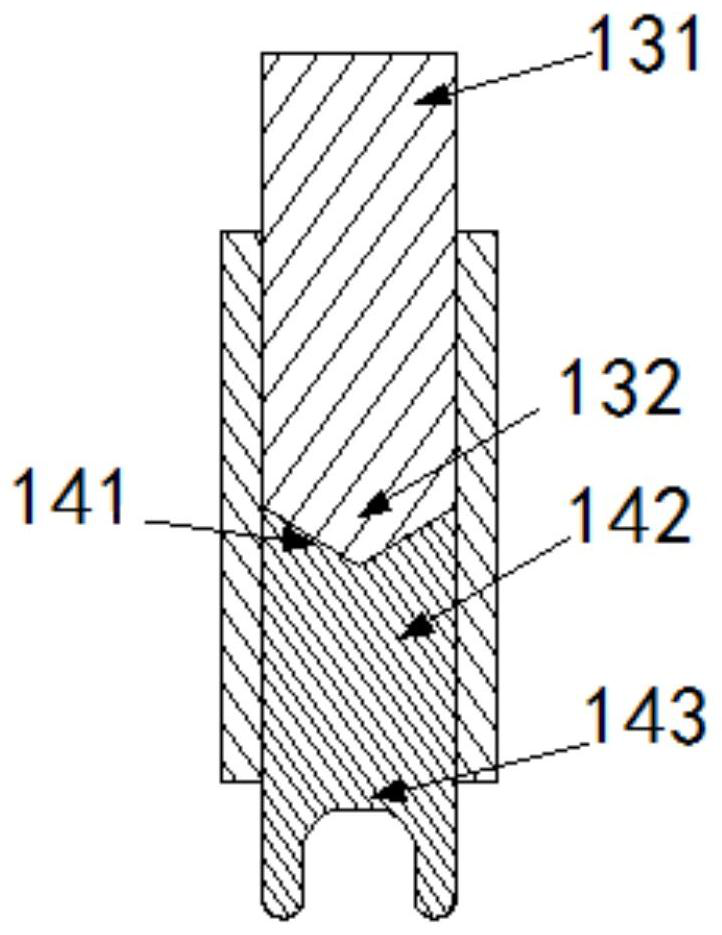

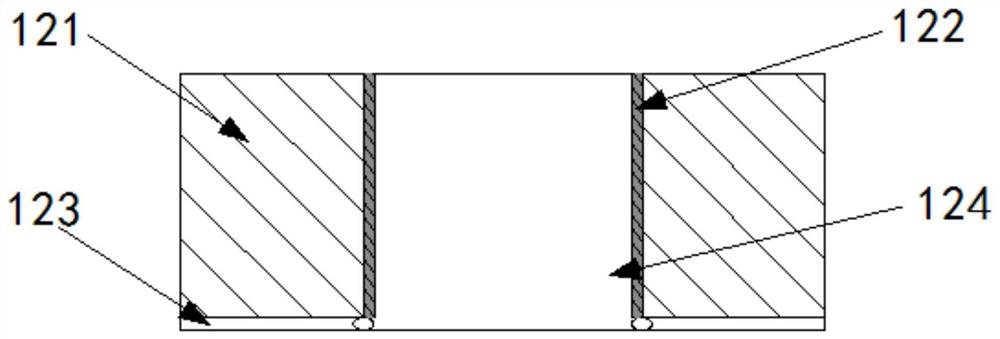

[0050] Such as figure 1 As shown, the friction riveting device between thermoplastic carbon fiber composite material and aluminum alloy according to the present invention specifically includes: die 111, blank holder 121, vacuum insulation tube 122, via hole 123, driving rod 131, rivet 140, rivet Cover 150 and connector, wherein, the lower part of the die 111 is a solid cylindrical structure, the center of the upper part is provided with a circular groove 112, and the bottom surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com