Titanyl sulfate hydrate powder, method for producing titanyl sulfate hydrate powder, method for producing aqueous titanyl sulfate solution, method of producing electrolyte solution, and method for producing redox flow battery

A technology of titanyl sulfate hydrate and its manufacturing method, which is applied to titanium compounds, fuel cells, electrochemical generators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

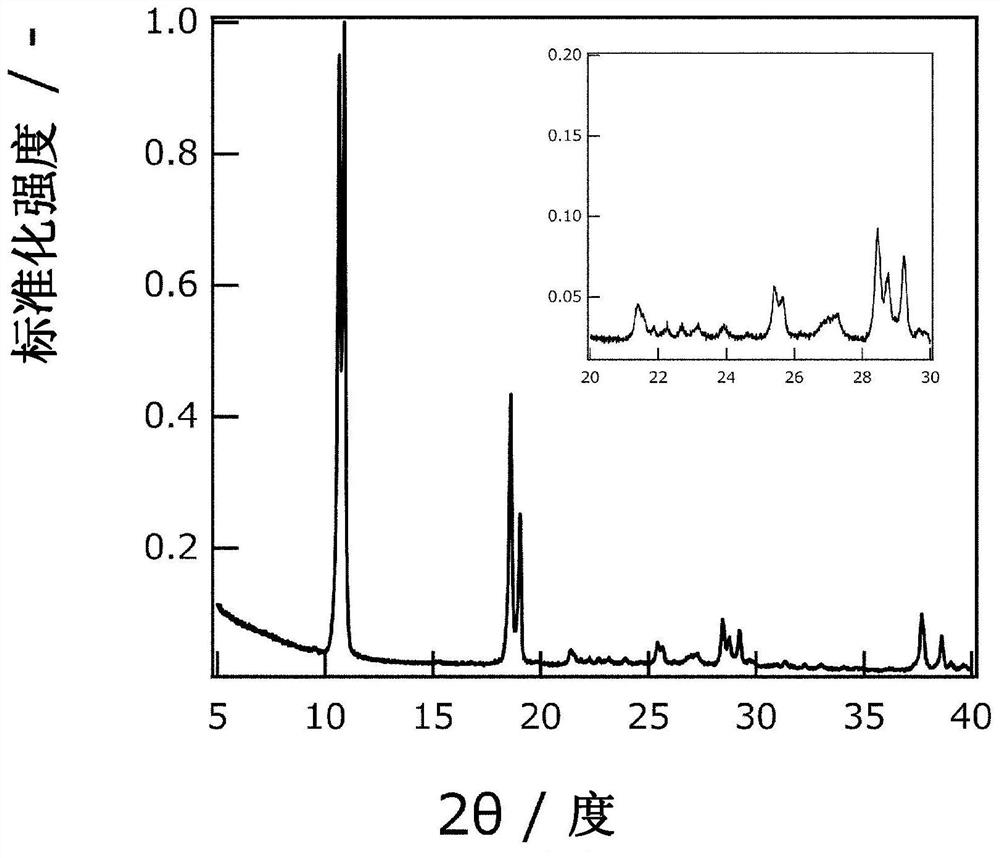

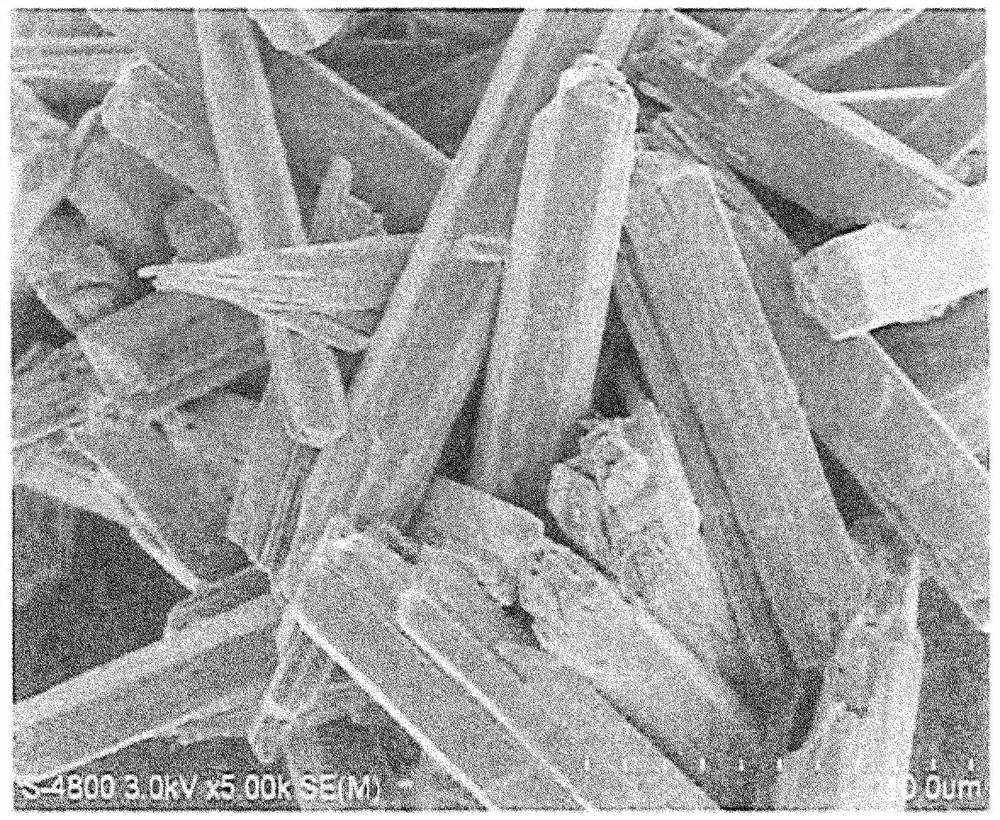

[0085] Hydrous titanium oxide containing niobium element is used as a starting material and dissolved in sulfuric acid to obtain a titanium sulfate solution. Add water and sulfuric acid to the obtained titanium sulfate solution, adjust the amount of each component, and obtain titanium element containing TiO 2 Converted to 110g / L, containing sulfur element as H 2 SO 4 It is 850 g / L in conversion, and the solution containing the niobium element of the molar ratio (Nb / Ti) of the niobium element and the titanium element becomes 0.0010. The mass ratio at this time (H 2 SO 4 / TiO 2 ) was 7.7, and the molar ratio (S / Ti) of sulfur element content relative to titanium element content was 6.3. The obtained titanium sulfate solution was put into a glass beaker and heated from room temperature to 70° C. over 10 minutes while stirring using a stirrer having a Teflon-finished stirring blade. During heating, when the temperature reaches 50° C., titanyl sulfate dihydrate crystals are ad...

Embodiment 2

[0088] In Example 1, except for the conditions of heating the titanium sulfate solution, the same operation was performed to obtain titanyl sulfate hydrate powder. The specific heating conditions are as follows. While continuing to stir the aqueous solution, it was heated from room temperature to 50° C. over 10 minutes. When 50°C was reached, seeds were added. Then, the temperature was raised to 70° C. over 10 minutes while continuing stirring, and the temperature was maintained at 70° C. for 4 hours, and then the heating was stopped and cooled. Table 1 shows the production conditions. In addition, Table 2 shows the results obtained by evaluating the obtained titanyl sulfate hydrate powder in the same manner as in Example 1.

Embodiment 3

[0090] In Example 1, TiO was obtained 2 Concentration is 90g / L, sulfuric acid concentration is 700g / L, H 2 SO 4 / TiO 2 Except that the titanium sulfate solution having a mass ratio of 7.8 and an S / Ti molar ratio of 6.3 was used to precipitate crystals, the same operation was performed to obtain titanyl sulfate hydrate powder. Table 1 shows the production conditions. In addition, Table 2 shows the results obtained by evaluating the obtained titanyl sulfate hydrate powder in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com