A kind of fine-grained cemented carbide and preparation method thereof

A cemented carbide and fine-grained technology, which is applied in the field of cemented carbide, can solve the problems of poor performance of fine-grained WC-based cemented carbide materials and unsatisfactory effects of grain growth inhibitors, etc., to improve the transverse fracture strength And wear resistance, improve hardness, improve the effect of transverse fracture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

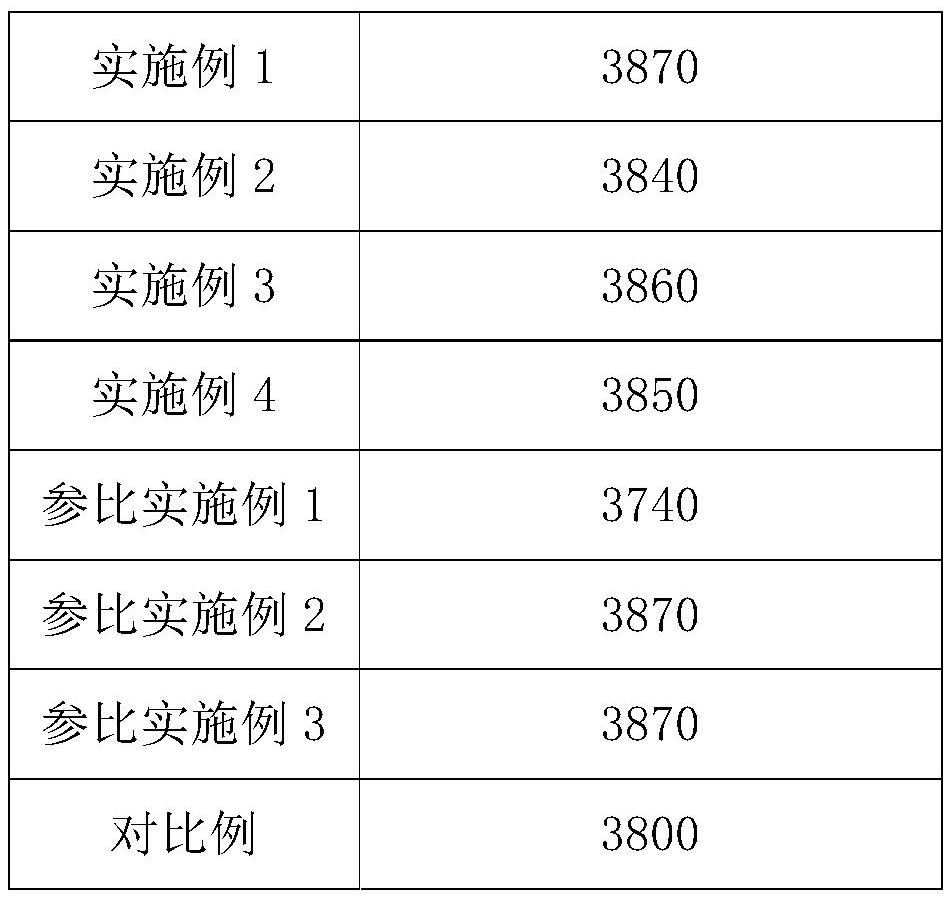

Embodiment 1

[0030] Fine-grained cemented carbide, prepared from the following components by weight percentage: 1% grain growth inhibitor, 12% cobalt powder with an average particle size of 1-1.5 μm, and the rest is carbonized powder with an average particle size of 0.2-0.5 μm For tungsten, the weight percentage sum of each component is 100%. Wherein, the grain growth inhibitor is made by the following steps:

[0031] Add niobium oxalate into the DMF ethanol solution and mix uniformly to prepare a solution with a concentration of 0.3mol / L, add chromium nitrate to the DMF ethanol solution and mix uniformly to obtain a solution with a concentration of 0.2mol / L, add rhenium nitrate to DMF ethanol Mix homogeneously in the solution and make concentration be the acetone solution of 0.04mol / L, add 3-phenylacetylacetone in the DMF ethanol solution and mix homogeneously make concentration be the acetone solution of 0.5mol / L, the volume ratio is 1:1: Mix A solution, B solution, C solution, and D so...

Embodiment 2

[0038] Fine-grained cemented carbide, prepared from the following components by weight percentage: 0.9% grain growth inhibitor, 14% cobalt powder with an average particle size of 1-1.5 μm, and the rest being carbonized powder with an average particle size of 0.2-0.5 μm For tungsten, the weight percentage sum of each component is 100%. Wherein, the preparation steps of the grain growth inhibitor are the same as in Example 1.

[0039] The preparation method of the fine-grained hard alloy comprises the following steps:

[0040] S1. Weigh each component by weight percentage, mix each component to obtain alloy powder, add alloy powder, polyoxyethylene octylphenol ether-10, and paraffin into a ball mill, and obtain a mixed slurry after wet ball milling for 24 hours. The ball-to-material ratio during wet ball milling is 5:1, the weight ratio of polyoxyethylene octylphenol ether-10 to alloy powder is 1:5, and the weight ratio of paraffin wax to alloy powder is 1:100;

[0041] S2. Sp...

Embodiment 3

[0045] Fine-grained cemented carbide, prepared from the following components by weight: 1.2% grain growth inhibitor, 10% cobalt powder with an average particle size of 1-1.5 μm, and the rest being carbonized powder with an average particle size of 0.2-0.5 μm For tungsten, the weight percentage sum of each component is 100%. Wherein, the preparation steps of the grain growth inhibitor are the same as in Example 1.

[0046] The preparation method of the fine-grained hard alloy comprises the following steps:

[0047] S1. Weigh each component by weight percentage, mix each component to obtain alloy powder, add alloy powder, polyoxyethylene octylphenol ether-10, and paraffin into a ball mill, and obtain a mixed slurry after wet ball milling for 48 hours. The ball-to-material ratio during wet ball milling is 5:1, the weight ratio of polyoxyethylene octylphenol ether-10 to alloy powder is 1:5, and the weight ratio of paraffin wax to alloy powder is 1:100;

[0048] S2. Spray-dry the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com