Comprehensive utilization method of columbite

A niobium ferro-niobium and ferro-niobium technology, applied in the field of smelting, can solve the problems of high recovery cost of niobium-iron ore and difficult separation of ferro-phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

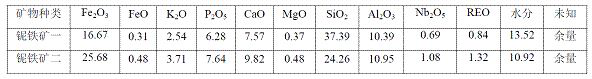

Embodiment 1

[0062] The niobium iron ore is directly sent to the feeding port of the side blowing furnace through the belt conveyor, and put into the furnace (the amount of pre-mixed coal is 0).

[0063] Once the niobium ore is put into the molten pool of the side-blowing furnace for reducing side-blowing smelting, coal powder and oxygen-rich gas are sprayed into the molten pool by the side-blowing lance. The oxygen-rich gas is composed of oxygen and air. , the main technical parameters of the side blowing furnace injection system are: coal powder 292kg, oxygen 290Nm 3 , air 131Nm 3 , the oxygen-enriched concentration is 75.07%, the temperature of the side-blowing furnace molten pool is 1450~1500℃, and it can produce 673kg of slag, 106kg of phosphorus-containing molten iron, 78kg of smoke and dust, and 784Nm of high-temperature flue gas 3 . Among them, the composition of slag: 3.22%FeO, 0.47%P 2 o 5 , 0.99%Nb 2 o 5 , 1.21%REO; composition of phosphorus-containing molten iron: 0.1%C, ...

Embodiment 2

[0067] The niobium-iron ore and anthracite are fed into the feed port of the side-blown furnace directly using a belt batching (100kg of anthracite is added to each ton of ore) according to the mass ratio of 100:10, and then put into the furnace.

[0068] Niobium iron ore and anthracite are put into the molten pool of side-blowing furnace for reduction and side-blown smelting. Coal powder and oxygen-rich gas are sprayed into the molten pool by side-blown lance. When mining, the main technical parameters of the side blowing furnace injection system are: coal powder 160kg, oxygen 268Nm 3 , air 37Nm 3 , the oxygen-enriched concentration is 89.98%, the temperature of the side-blowing furnace molten pool is 1350~1400℃, and it can produce 668kg of slag, 109kg of phosphorus-containing molten iron, 75kg of smoke and dust, and 650Nm of high-temperature flue gas 3 . Among them, slag composition: 2.57%FeO, 0.94%P 2 o 5 , 1.00%Nb 2 o 5 , 1.22%REO; composition of phosphorus-containin...

Embodiment 3

[0072] The niobium-iron ore and anthracite are fed into the feed port of the side-blowing furnace directly using a belt batching (400kg of anthracite is added to each ton of ore) according to the mass ratio of 100:40, and then put into the furnace.

[0073] Niobite II and anthracite are put into the molten pool of side-blowing furnace for reduction and side-blowing smelting. Natural gas and oxygen-rich gas are sprayed into the molten pool by side-blowing lance. The oxygen-rich gas is composed of oxygen and air. , the main technical parameters of the side blowing furnace injection system are: natural gas 30Nm 3 , oxygen 278Nm 3 , air 722Nm 3 , the oxygen-enriched concentration is 42.83%, the temperature of the side-blowing furnace molten pool is 1350~1400℃, and it can produce 605kg of slag, 172kg of phosphorus-containing molten iron, 91kg of smoke and dust, and 1410Nm of high-temperature flue gas 3 . Among them, slag composition: 3.22%FeO, 0.63%P 2 o 5 , 1.74%Nb 2 o 5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com