Multi-functional-group high-absorption chrome tanning auxiliary agent as well as preparation method and application thereof

A multifunctional, high absorption technology, applied in the application, nitrile preparation, carboxylate/lactone preparation, etc., can solve the problems of poor chromium fixability, unable to meet the needs of high absorption chrome tanning process, etc. Promote cleaner production and improve the effect of coordination sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Synthesis of Polycarboxylic Ester

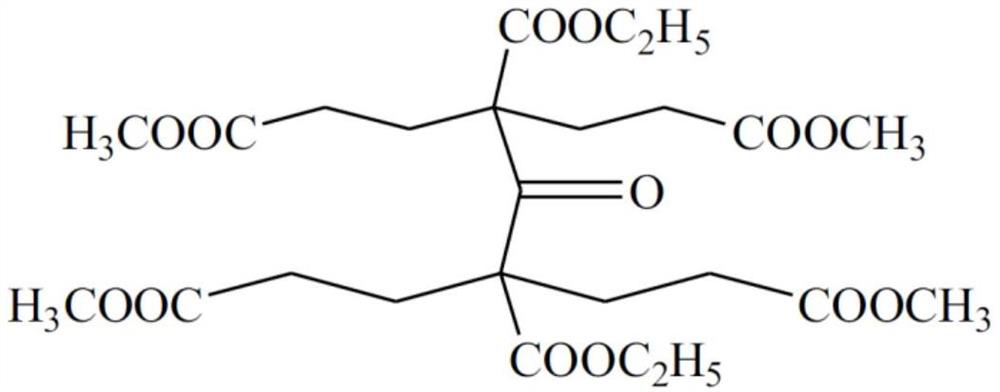

[0032] Add 0.1 mol of diethyl 3-ketoglutarate, ground and dried K 2 CO 3 (0.02mol), 1g tetrabutylammonium bromide and 500mL n-hexane, add dropwise 0.41mol methyl acrylate, about 20min to finish dripping, reflux reaction for 6h, stop, suction filtration, filter, extract n-hexane, precipitate solid, pump Filter polycarboxylate, product structural formula is as follows:

[0033]

[0034] (2) Hydrolysis of polycarboxylic acid ester

[0035] Add 0.1mol of polycarboxylic acid ester to a 500mL four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, add 200mL of potassium hydroxide solution with a mass fraction of 20%, stir at 60°C for 2 hours, and then adjust the pH to 4-5. Filter to obtain the product, and dry it in a vacuum oven at 65°C for 4 hours. The structural formula of the product is as follows:

[0036]

[0037] H NMR spectra of polycarboxylates (DMSO-d6)

[0038] 4.08ppm (q,4H,-COOCH 2 CH ...

Embodiment 2

[0044] (1) Synthesis of tetravalent nitrile esters

[0045] Add 0.1 mol of diethyl 3-ketoglutarate, ground and dried K 2 CO 3 (0.02mol), 2g tetrabutylammonium bromide and 500mL n-hexane, add dropwise 0.41mol acrylonitrile, drop it for about 20min, reflux for 6h, stop, suction filter, filter, remove n-hexane, precipitate solid, suction filter Obtain tetravalent nitrile ester, product structural formula is as follows:

[0046]

[0047] (2) Hydrolysis of tetravalent nitrile ester

[0048] In a 500mL four-neck flask equipped with a stirrer, a thermometer, and a reflux condenser, add 0.1mol of tetravalent nitrile ester, add 200mL of potassium hydroxide solution with a mass fraction of 20%, stir at 60°C for 2h, and adjust the pH to 4-5. Filter to obtain the product, and dry it in a vacuum oven at 65°C for 4 hours. The structural formula of the product is as follows:

[0049]

[0050] H NMR spectrum of tetravalent nitrile esters (DMSO-d6)

[0051] 4.08ppm (q,4H,-COOCH 2 C...

Embodiment 3

[0056] (1) Synthesis of Polycarboxylic Ester

[0057] Add 0.1 mol of diethyl dibenzoate acetone, ground and dried K 2 CO 3 (0.02mol), 3.2g polyethylene glycol 1000 (PEG1000) and 500mL petroleum ether, add 0.42mol methyl acrylate dropwise, drop it for about 20min, reflux for 5h, stop, filter with suction, filter, and let the filtrate stand and remove Sherwood oil, separate out solid, obtain polycarboxylate by suction filtration, product structural formula is as follows:

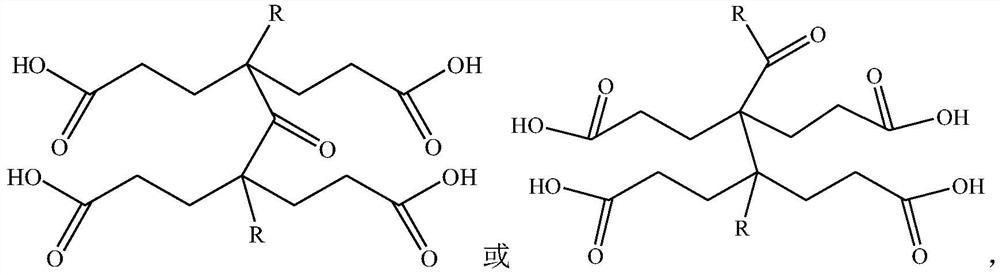

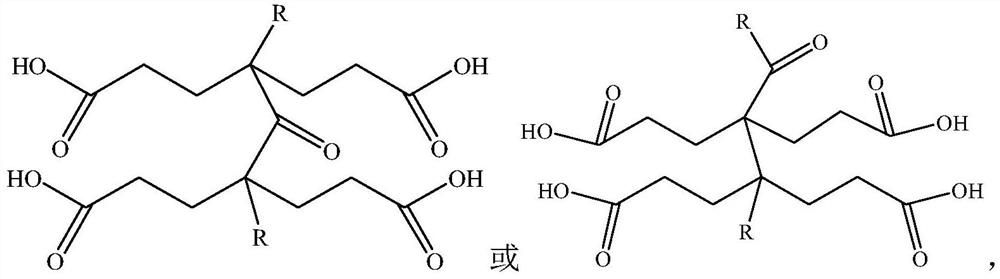

[0058]

[0059] (2) Hydrolysis of polycarboxylic acid ester

[0060] Add 0.1mol polycarboxylic acid ester to a 500mL four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, add 250mL of a 25% sodium hydroxide solution, stir at 65°C for 7h, and then adjust the pH with acid To 4-5, filter to obtain the product, and dry it in a vacuum oven at 65°C for 4 hours. The structural formula of the product is as follows:

[0061]

[0062] H NMR spectrum of polycarboxylates (DMSO-d6)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com