Germanium-arsenic-selenium-tellurium (GeAsSeTe) powder for semiconductor memory, target material and preparation method of GeAsSeTe powder

A memory and semiconductor technology, applied in chemical instruments and methods, selenium/tellurium compounds, binary selenium/tellurium compounds, etc., can solve the problem of volatile, unsuitable for large-scale industrial production of germanium, arsenic, selenium and tellurium compounds, and equipment dependence Large and other problems, to achieve the effect of uniform composition, high density and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the GeAsSeTe powder for the semiconductor memory of the present invention comprises the following steps:

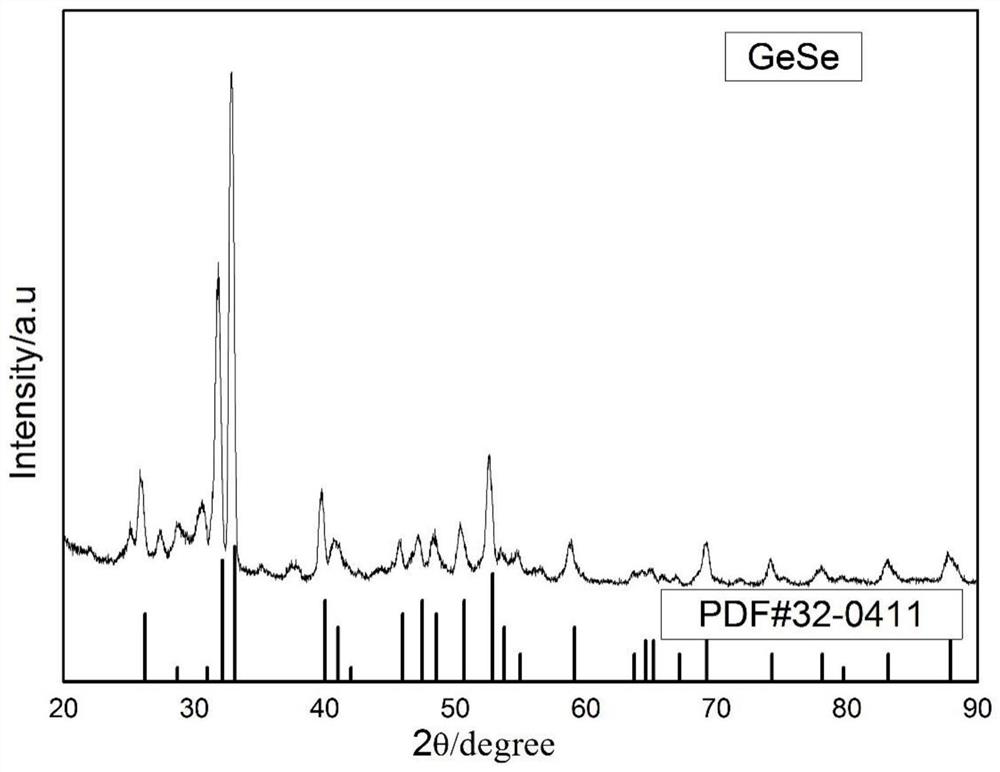

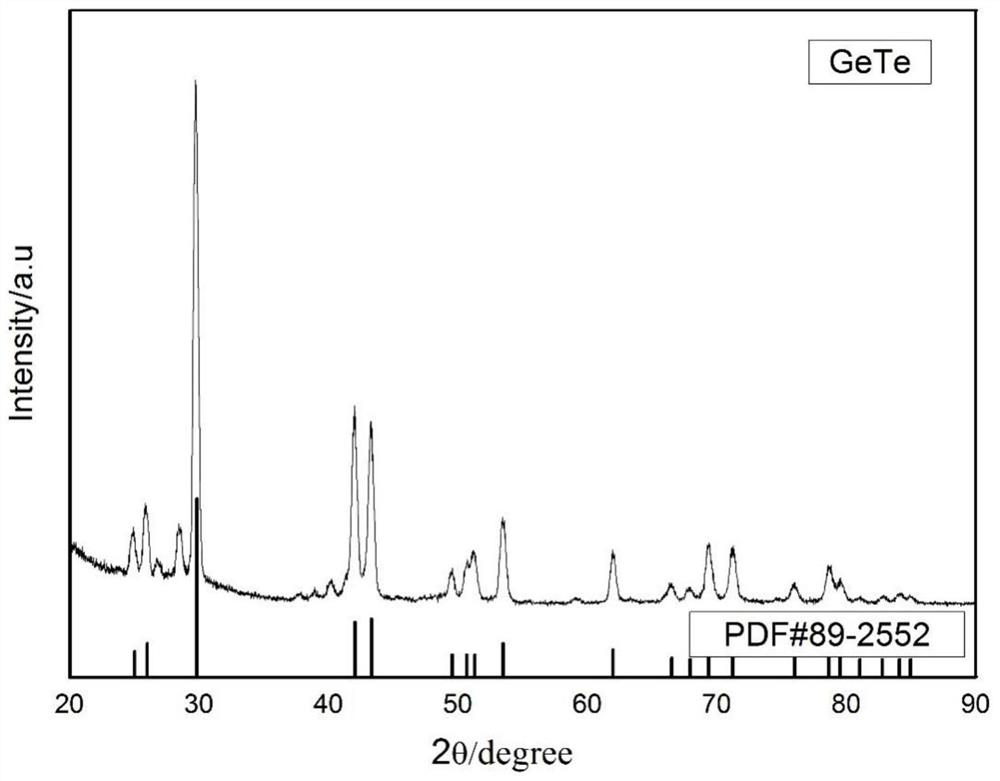

[0036] (1) Mix Se block and As block, Ge block and Te block, Ge block and Se block respectively and put them in a quartz boat and send them into the tube furnace. Nitrogen gas is first introduced into the furnace at a rate of 10 L / min and kept Exclude the air for 30 to 40 minutes. After the quartz boat is put in and continue to ventilate for 20 to 30 minutes, introduce a mixed protective atmosphere with a volume ratio of nitrogen and hydrogen of 7:3 and heat up at 5°C / min and keep it warm to obtain AsSe alloys. , GeTe alloy and GeSe alloy; the Se block and the As block are mixed according to the atomic ratio of Se and As 1:1; the Ge block and the Te block are mixed according to the atomic ratio of Ge and Te 1:1; the Ge The block and the Se block are mixed according to the atomic ratio of Ge and Se at 1:1; the heating and heat preservation ...

Embodiment 2

[0043] The preparation method of the GeAsSeTe powder for the semiconductor memory of the present invention comprises the following steps:

[0044] (1) Mix Se block and As block, Ge block and Te block, Ge block and Se block respectively and put them in a quartz boat and send them into the tube furnace. Nitrogen gas is first introduced into the furnace at a rate of 10 L / min and kept Exclude the air for 30-40 minutes. After the quartz boat is put in and continue to ventilate for 20-30 minutes, introduce a mixed protective atmosphere with a volume ratio of nitrogen and hydrogen of 7:4 and heat up at 10°C / min and keep it warm to obtain AsSe alloys respectively. , GeTe alloy and GeSe alloy; the Se block and the As block are mixed according to the atomic ratio of Se and As 1:1; the Ge block and the Te block are mixed according to the atomic ratio of Ge and Te 1:1; the Ge The block and the Se block are mixed according to the atomic ratio of Ge and Se at 1:1; the heating and heat prese...

Embodiment 3

[0050] The preparation method of the GeAsSeTe powder for the semiconductor memory of the present invention comprises the following steps:

[0051] (1) Mix Se block and As block, Ge block and Te block, Ge block and Se block respectively and put them in a quartz boat and send them into the tube furnace. Nitrogen gas is first introduced into the furnace at a rate of 10 L / min and kept Exclude the air for 30 to 40 minutes. After the quartz boat is put in and continue to ventilate for 20 to 30 minutes, introduce a mixed protective atmosphere with a volume ratio of nitrogen and hydrogen of 7:3 and heat up at 5°C / min and keep it warm to obtain AsSe alloys. , GeTe alloy and GeSe alloy; the Se block and the As block are mixed according to the atomic ratio of Se and As 1:1; the Ge block and the Te block are mixed according to the atomic ratio of Ge and Te 1:1; the Ge The block and the Se block are mixed according to the atomic ratio of Ge and Se at 1:1; the heating and heat preservation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com