Method for forming Monel metal bar under vacuum state

An alloy bar, vacuum state technology, applied in the forming of monel alloy, the forming field of monel alloy bar in vacuum state, can solve the problem that the tensile yield can only reach 30%, which restricts the large-scale promotion of products and Application, low material utilization and other problems, to avoid microscopic defects, improve material utilization efficiency, and fast pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

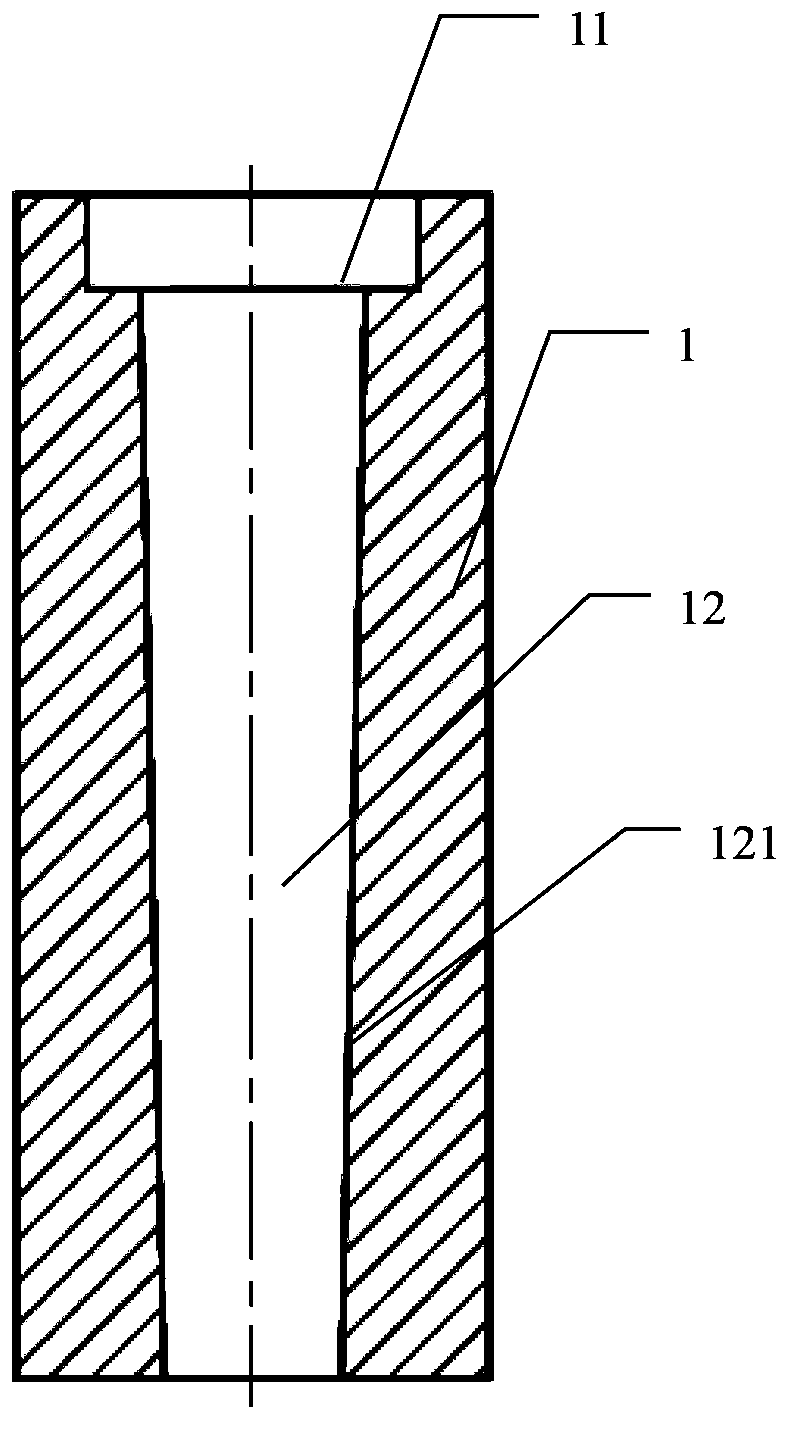

[0018] The embodiment of the present invention provides a method for forming Monel alloy rods in a vacuum state, figure 1 It is a structural schematic diagram of a steel ingot mold for a forming method of a Monel alloy bar in a vacuum state according to an embodiment of the present invention.

[0019] The forming method of a kind of Monel alloy bar provided in this embodiment under vacuum state is to carry out smelting and pouring forming of Monel alloy under vacuum condition, after Monel alloy is smelted into molten steel in a vacuum furnace, through A special steel ingot mold is solidified and formed under vacuum conditions to produce a Monel alloy steel ingot with stable performance. Nell alloy bars.

[0020] In order to adapt to the temperature conditions of Monel pouring, the steel ingot mold described in this example adopts a special high-temperature-resistant high-chromium-nickel alloy ductile iron material (Cr: 30%, Ni: 12%), and its room temperature tensile strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com