Alkali polishing device and polishing process for crystalline silicon wafer

A technology of polishing device and silicon chip alkali, which is applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tool, etc., can solve the problems of wear and tear on the lower surface of crystal silicon chip, deposition, and flat surface unevenness, and achieve Avoid turning or moving, avoid mechanical damage, improve the effect of polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] The following will be combined with embodiments of the present invention, the technical solution in the embodiment of the present invention is clearly and completely described, it is clear that the embodiments described are only a part of the embodiment of the present invention, not all embodiments. Based on embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative work, are within the scope of protection of the present invention.

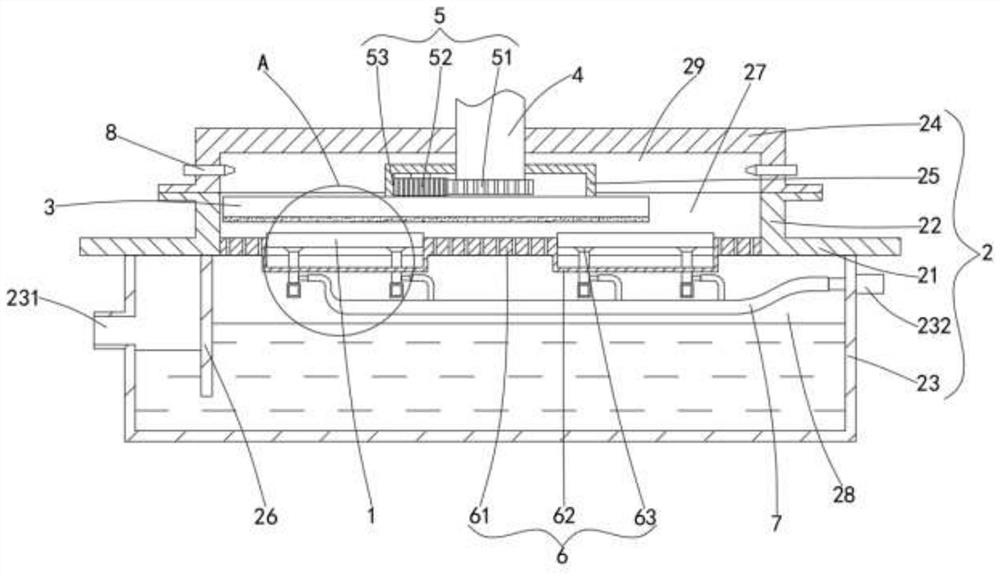

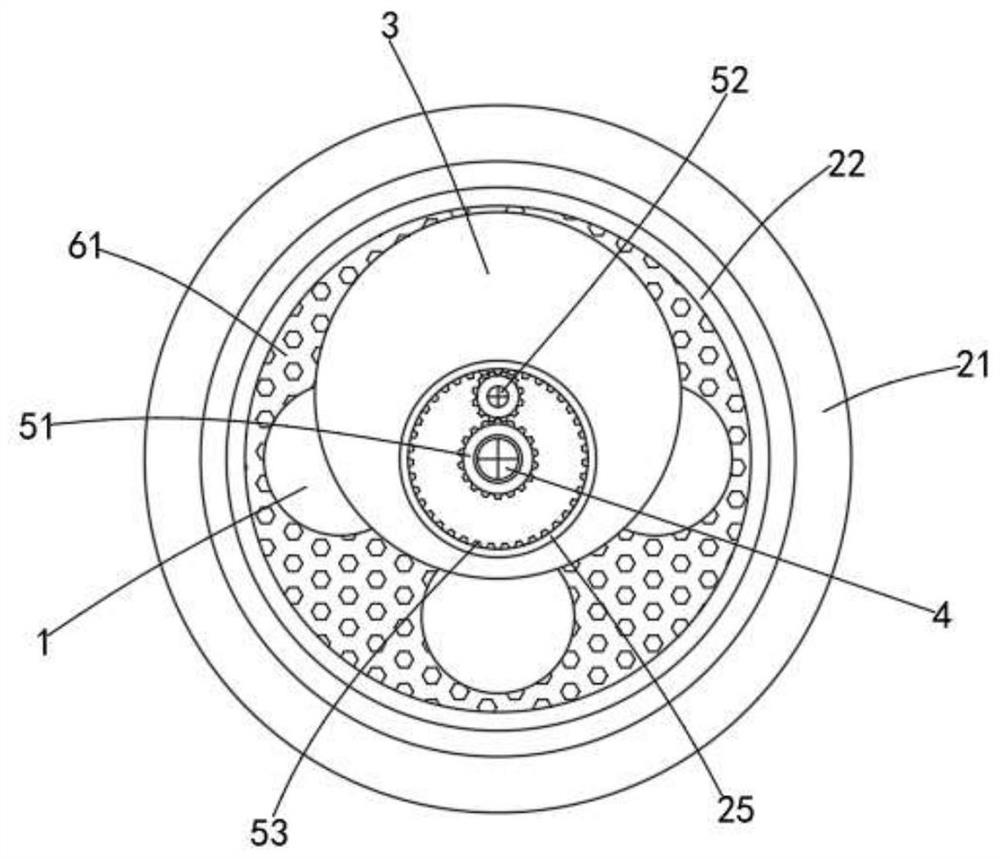

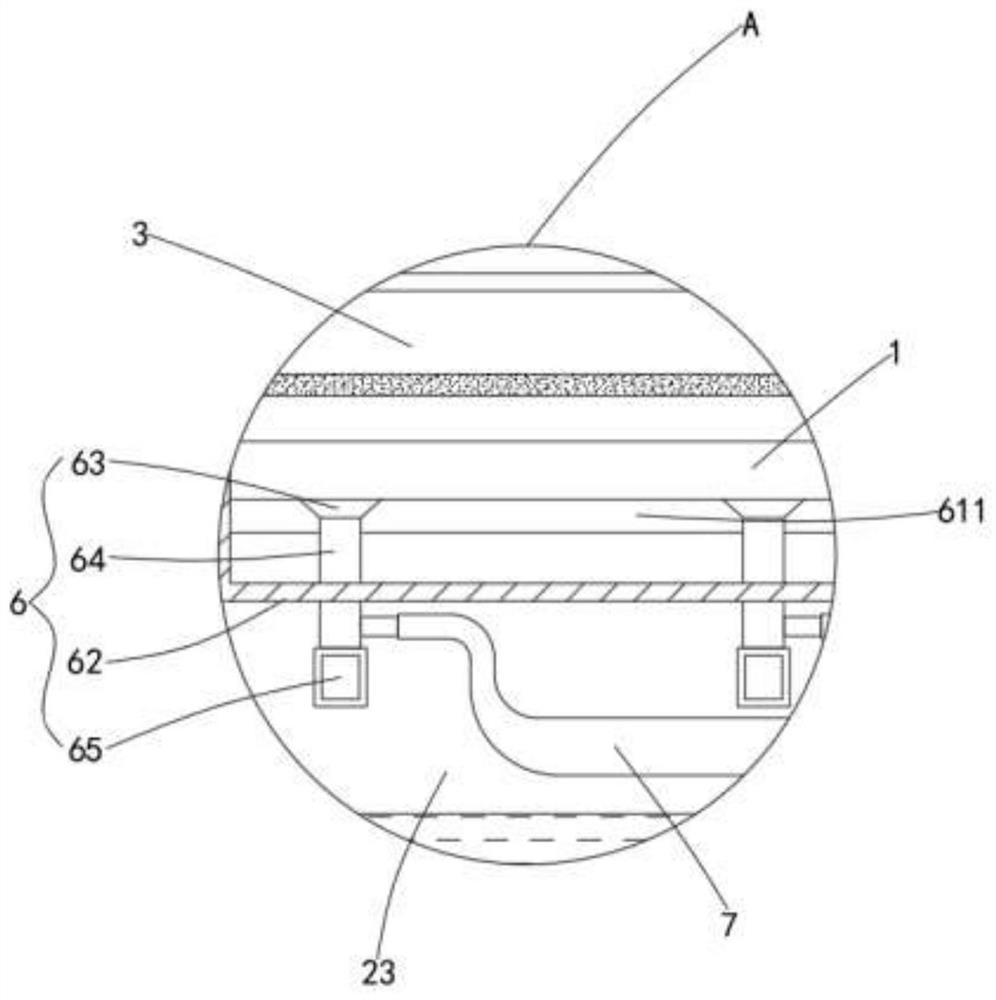

[0034] as Figure 1 As shown, a crystalline silicon wafer alkali polishing apparatus of the present invention, comprising a workpiece 1, further comprising a device body 2, a polishing die 3, a hinge 4, a transmission mechanism 5, a fixed assembly 6, a suction pipe 7 and several nozzles 8.

[0035] Wherein, the apparatus body 2 includes a platform 21, a first cylinder 22, a second cylinder 23 and a first cylinder head 24, a horizontal setting of platform 21.

[0036] The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com