A method for preparing active filler by using hydroxyapatite, zero-valent iron and humic acid and its application

A technology of hydroxyapatite and active filler, which is applied in the restoration of polluted soil and other directions, can solve the problems of reducing the reactivity and effectiveness of zero-valent iron, unable to degrade pollutants lastingly, and reducing the possibility of engineering application, etc. To achieve the effect of improving adsorption performance, slowing down the surface passivation process and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

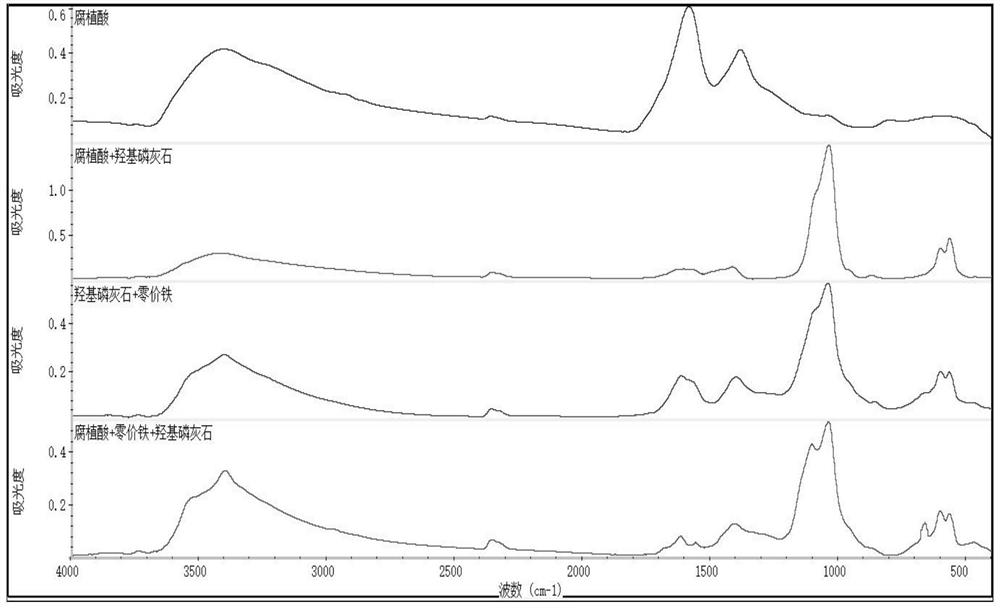

Image

Examples

Embodiment 1

[0030] 1) Hydroxyapatite is passed through a 200-mesh sieve. Add 1 g of fulvic acid (FA ≥ 90%) and 20 mL of ammonia water into 1 L of distilled water and mix to prepare a humic acid solution. Weigh 2g of the sieved hydroxyapatite particles in 20mL humic acid solution and let it stand at room temperature for 24 hours; vacuum filter and wash with distilled water until neutral; put the obtained material in a weighing bottle and place it in the refrigerator at -20°C Freeze for 48 hours, take it out, and dry it with a freeze dryer for 5 hours. The obtained modified hydroxyapatite is stored in a sealed bag for future use.

[0031] 2) Weigh 3.18g ferrous sulfate heptahydrate and dissolve in 50mL alcohol-water mixture (V 水 :V 乙醇 =6:4), ultrasonic 5min, after stirring until completely dissolved, the ferrous sulfate solution was added in the three-necked flask, the above-mentioned modified hydroxyapatite was added in the three-necked flask, and stirred at 100 rev / min at room temperatu...

Embodiment 2

[0034] 1) Hydroxyapatite is passed through a 180-mesh sieve. Add 1 g of fulvic acid (FA ≥ 90%) and 20 mL of ammonia water into 1 L of distilled water and mix to prepare a humic acid solution. Weigh 4g of the sieved hydroxyapatite particles in 20mL humic acid solution and leave it at room temperature for 24 hours; vacuum filter and wash with distilled water until neutral; put the obtained material in a weighing bottle and place it in the refrigerator at -20°C Freeze for 60 hours, take it out and dry it with a freeze dryer for 5 hours, and store the modified hydroxyapatite in a sealed bag for future use.

[0035] 2) Weigh 6.68g ferrous sulfate heptahydrate and dissolve it in 200mL alcohol-water mixture (V 水 :V 乙醇 =6:4), ultrasonic 10min, after stirring until completely dissolved, the ferrous sulfate solution is added in the three-necked flask, the above-mentioned modified hydroxyapatite is added in the three-necked flask, stirred at 100 rev / min at room temperature 2h; Weigh 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com