Interface thermocatalytic system

A catalytic system, interfacial heat technology, applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve problems such as environmental pollution and energy consumption, and achieve the effect of high chemical reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

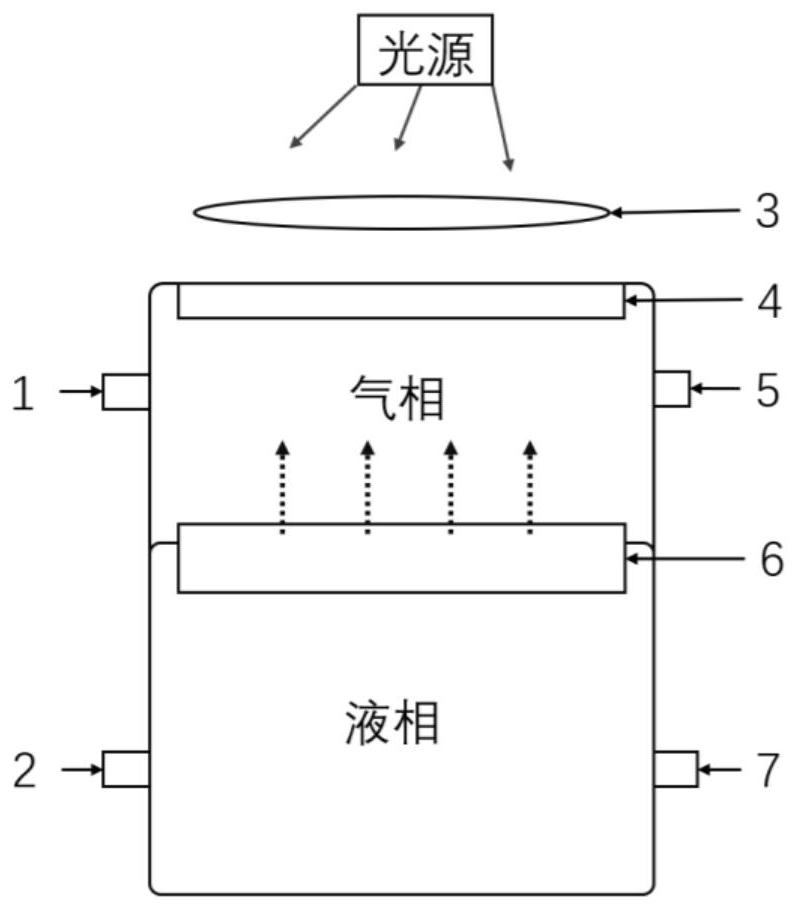

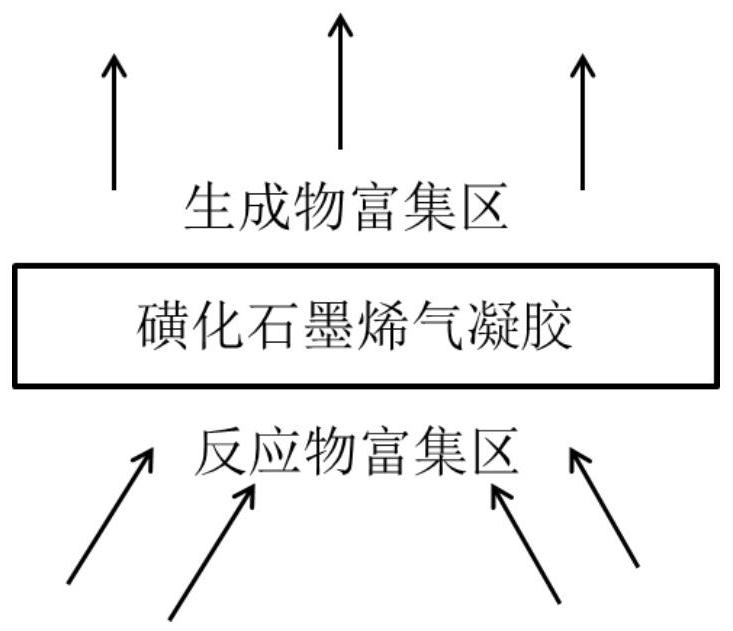

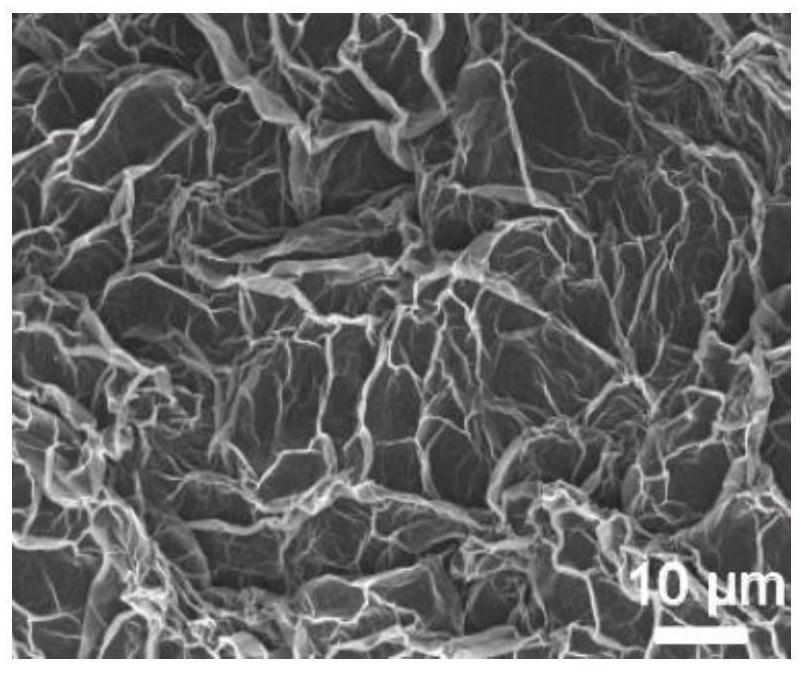

[0025] Such as figure 1 As shown, the present invention provides a kind of interfacial thermocatalytic system, comprises the sulfonated graphene airgel 6 that is grafted with the sulfonate group that is used to catalyze the reaction of ethyl acetate, and the grafted sulfonate group can be obtained by placing the graphene aerogel It is realized in common sulfonation reagents such as concentrated sulfuric acid and chlorosulfonic acid, and the sulfonated graphene airgel 6 can float on the surface of the reaction solution. The system also includes a reactor containing reactants, a light-transmitting quartz glass 4 and a light source that are covered on the top of the reactor, and a condenser lens 3 is placed between the light-transmitting quartz glass 4 and the light source. The reactor is made of acid-resistant stainless steel. Acid and corrosion resistance, at the same time, there is a sensor installation port 1 on the side wall for installing pressure measuring probes and tempe...

Embodiment 2

[0032] The basic system composition is the same as that of Example 1, and the difference from Example 1 is that the carrier is porous carbon, which is sulfonated by concentrated sulfuric acid to catalyze the reaction of ethyl formate.

[0033] The two reactants of formic acid and ethanol are mixed and added into the reactor according to the ratio of 1:1, the prepared porous carbon with catalytic activity is placed in it, the intensity of the light source is adjusted so that the surface temperature of the catalyst reaches the boiling point of ethyl formate, and then The reaction is continued until it stabilizes and eventually a conversion of at least 50% can be obtained.

Embodiment 3

[0035] The basic system is the same as that of Example 1. The difference from Example 1 is that the carrier is silica gel aerogel doped with graphite powder, and the catalyst is zeolite molecular sieve. The zeolite molecular sieve is introduced in the process of synthesizing the airgel to catalyze the nitration reaction.

[0036] Mix the two reactants of toluene and nitric acid into the reactor according to the ratio of 1:1, place the prepared airgel catalyst in it, adjust the intensity of the light source so that the reaction temperature of the catalyst reaches the boiling point of the nitration product, and then continue the reaction Until stabilization, a conversion of at least 60% can eventually be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com