Converter module function detection device and method

A technology of functional testing and testing methods, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems of large resource consumption, large size of testing equipment, and high testing and testing costs, achieve low cost and energy consumption, and reduce disassembly and assembly. Risk, high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0057] The converter module function detection device of the present invention is suitable for detecting each converter module in the traction converter installed on rail trains, and is also suitable for detecting the converter modules before leaving the factory, especially Suitable for on-site inspection and maintenance. Now take the three-phase converter module as an example to illustrate (the detection device and method itself are not limited by the phase number of the converter module, and are also applicable to the detection of single-phase converter modules or four-phase converter modules, etc.) :

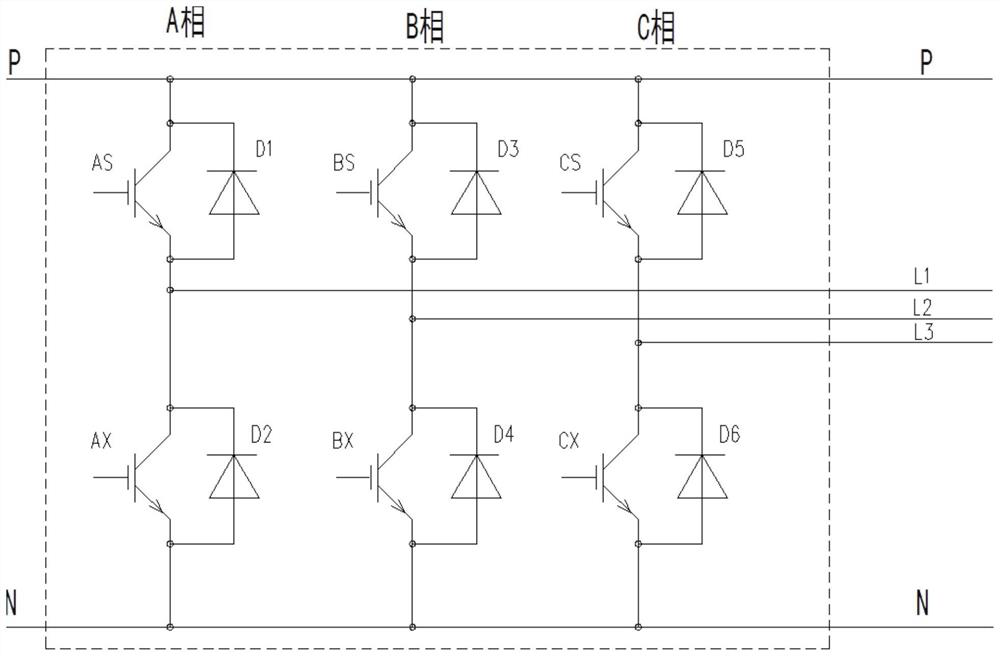

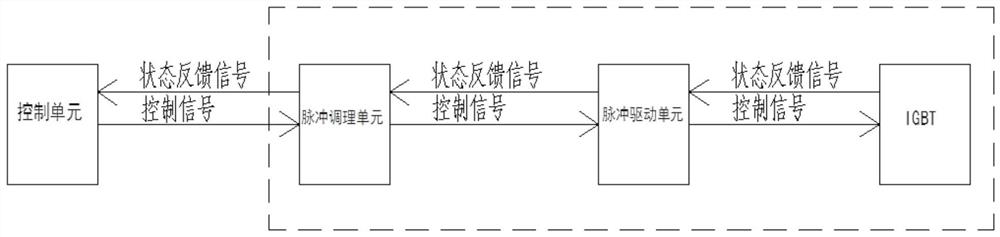

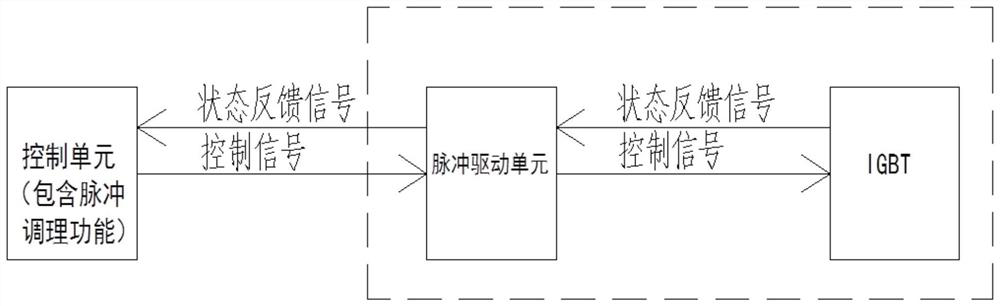

[0058] Such as figure 1 As shown, the main circuit of the three-phase converter module includes three phases A, B, and C, and each phase is composed of two upper and lower switching elements (such as IGBT elements) and their parallel-connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com