Preparation method of nitrogen-doped spherical graphene loaded flaky molybdenum disulfide catalyst

A molybdenum disulfide, nitrogen doping technology, used in electrodes, electrolysis processes, electrolysis components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of the nitrogen-doped spherical graphene-supported flake molybdenum disulfide catalyst described in the present invention realizes the regulation and control of flake molybdenum disulfide loaded in the spherical graphene by changing the nitrogen-doped structure in the spherical graphene, In order to control the catalytic activity of the nitrogen-doped spherical graphene-supported sheet-like molybdenum disulfide catalyst in the electrocatalytic hydrogen evolution reaction, the specific steps are as follows:

[0046] (1) Preparation of positively charged polystyrene microspheres

[0047] Mixture 1 was obtained by dissolving 10.0 g of styrene and 1.5 g of polyvinylpyrrolidone in 100.0 ml of deionized water in a 500 ml three-necked flask. The mixture was stirred mechanically at room temperature for 30 minutes under nitrogen protection. Then 0.26 g of 2,2'-azobisisobutylamidine dihydrochloride was dissolved in 20.0 ml of deionized water and added to m...

Embodiment 2

[0054] (1) This step is the same as step (1) in Example 1.

[0055] (2) This step is the same as step (2) in Example 1.

[0056] (3) This step is the same as step (3) in Example 1, and the solid sample is 2 The temperature of calcination in the atmosphere is adjusted to 3°C / min at 420°C -1 Calcined at a heating rate of 2 hours at 5°C / min -1 The heating rate was increased to 750 °C and then calcined for 1 hour to obtain nitrogen-doped spherical graphene mainly composed of pyridinic nitrogen, which was labeled as nitrogen-doped spherical graphene 2. The specific surface area, nitrogen-doped structure and nitrogen-doped content of nitrogen-doped spherical graphene 2 are listed in Table 1 and Table 2, respectively.

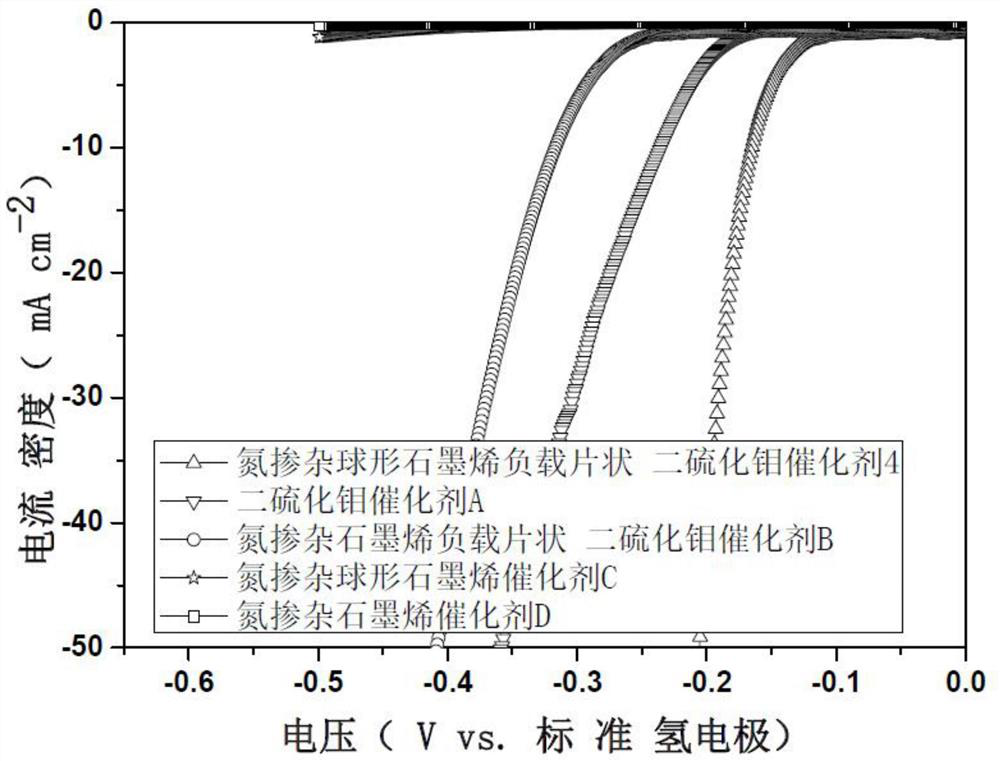

[0057] (4) This step is the same as step (4) in embodiment 1, obtains nitrogen-doped spherical graphene supported flake molybdenum disulfide catalyst 2. The polarization curve of nitrogen-doped spherical graphene-supported sheet-like molybdenum disulfide catalyst ...

Embodiment 3

[0059] (1) This step is the same as step (1) in Example 1.

[0060] (2) This step is the same as step (2) in Example 1.

[0061] (3) This step is the same as step (3) in Example 1, and the solid sample is 2 The temperature of calcination in the atmosphere is adjusted to 3°C / min at 420°C -1 Calcined at a heating rate of 2 hours at 5°C / min -1 The heating rate was increased to 1000°C and then calcined for 1 hour to obtain nitrogen-doped spherical graphene mainly composed of graphitic nitrogen, which was labeled as nitrogen-doped spherical graphene 3. The specific surface area, nitrogen-doped structure and nitrogen-doped content of nitrogen-doped spherical graphene 3 are listed in Table 1 and Table 2, respectively.

[0062] (4) This step is the same as step (4) in Example 1, and obtains nitrogen-doped spherical graphene supported flake molybdenum disulfide catalyst 3. The electrocatalytic hydrogen evolution polarization curve of nitrogen-doped spherical graphene-supported shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com