Etching solution for photoelectrochemical etching of gallium nitride

A photoelectrochemical and gallium nitride technology, applied in chemical instruments and methods, circuits, electrical components, etc., can solve problems such as cost and energy loss, adverse environmental impact, and material damage, and achieve the elimination of lattice damage and environmental hazards. The effect of low equipment requirements and reduced etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

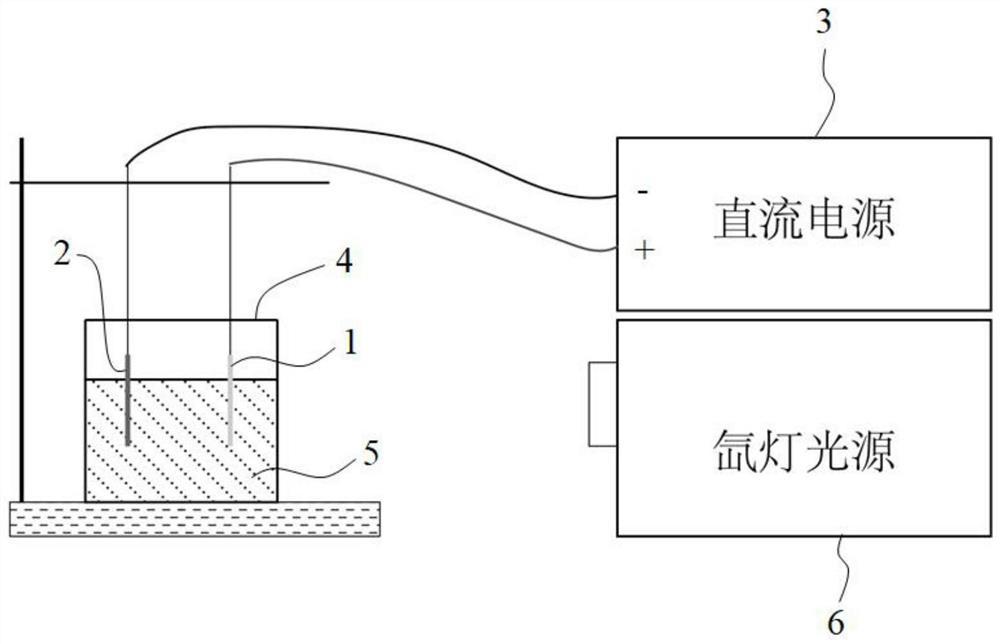

[0041] This embodiment provides an etching solution for photoelectrochemical etching of gallium nitride, wherein glycine is used as an etchant, deionized water is used as a solvent, and glycine is dissolved in deionized water to form an etching solution.

[0042] Specifically, in this embodiment, the weight percentage of glycine is 20%, the weight percentage of deionized water is 80%, and a saturated glycine aqueous solution is prepared as an etching solution. The etching solution of this embodiment does not add additives.

[0043] In this embodiment, the above-mentioned etching solution is used to perform photoelectrochemical etching on the gallium nitride epitaxial wafer, including the following steps:

[0044] (1) Soak a 1.1cm×0.3cm GaN epitaxial wafer in aqua regia and wash it for 5 minutes.

[0045] (2) Put the GaN epitaxial wafer obtained in step (1) into acetone, ethanol, and deionized water in sequence for ultrasonic cleaning for 15 minutes each.

[0046] (3) Using a...

Embodiment 2

[0055] This embodiment provides an etchant for photoelectrochemical etching of gallium nitride, wherein L-glutamic acid is used as an etchant, formic acid is used as a solvent, and L-glutamic acid is dissolved in formic acid to form an etching solution. liquid.

[0056] Specifically, in this embodiment, the weight percentage of L-glutamic acid is 20%, the weight percentage of formic acid is 80%, and a saturated L-glutamic acid formic acid solution is prepared as an etching solution. The etching solution of this embodiment does not add additives.

[0057] In this embodiment, referring to the etching process steps (1) to (6) in Embodiment 1, the GaN epitaxial wafer is photoelectrochemically etched using the etching solution as described above in this embodiment.

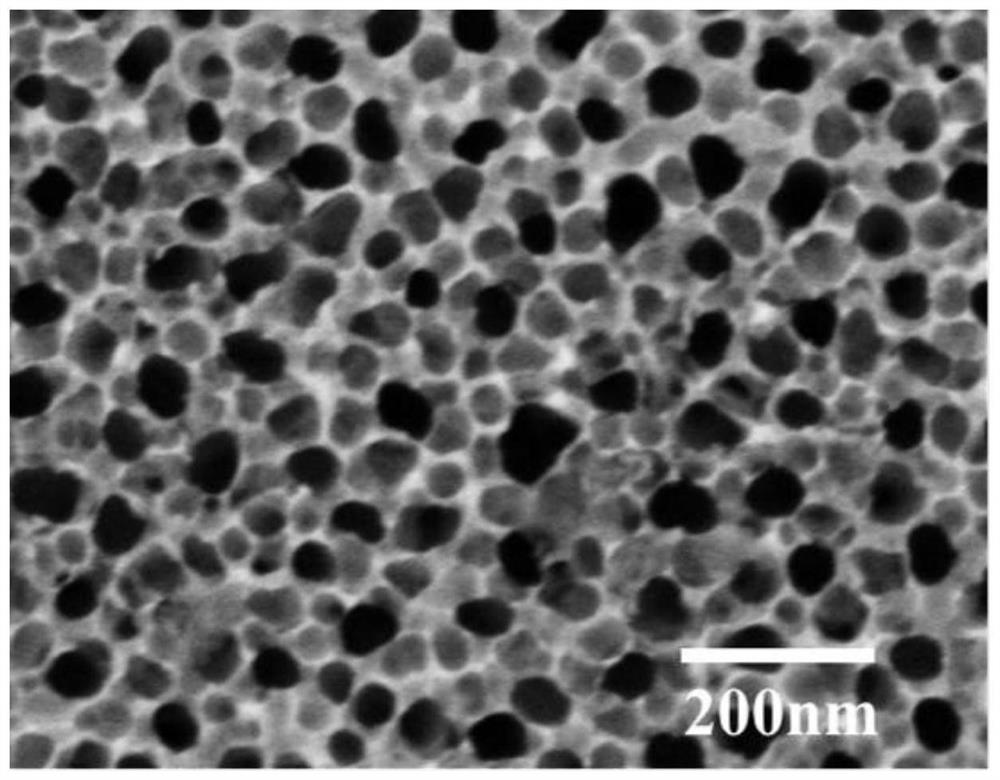

[0058] Figure 4 It is the SEM picture of the GaN epitaxial wafer after etching in this embodiment, as Figure 4 shown, with figure 2 Compared with this GaN epitaxial wafer, the hierarchical structure of the etche...

Embodiment 3

[0060] This embodiment provides an etching solution for photoelectrochemical etching of gallium nitride, wherein methyl aspartame is used as an etchant and citric acid is used as a solvent to dissolve methyl aspartame Form etchant in citric acid. The etching solution of this embodiment also added 1-ethyl-3-methylimidazolium trifluoromethanesulfonate as an auxiliary agent.

[0061] Specifically, the percentage by weight of aspartame in the present embodiment is 15%, the percentage by weight of formic acid is 80%, and the percentage by weight of 1-ethyl-3-methylimidazole trifluoromethanesulfonate is 5%. %, prepared as saturated aspartame citric acid solution as etching solution.

[0062] In this embodiment, referring to the etching process steps (1) to (6) in Embodiment 1, the GaN epitaxial wafer is photoelectrochemically etched using the etching solution as described above in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com