Front conductive paste for crystalline silicon solar cell, preparation method thereof, and solar cell

A technology for solar cells and conductive pastes, applied in the field of solar cells, can solve the problems of increased surface resistance of front electrodes and silicon wafers, inability to etch the anti-reflection insulating layer, and reduced photoelectric conversion efficiency of cells, and achieve excellent etching results. The effect of corrosion resistance and adhesion, strong adhesion and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

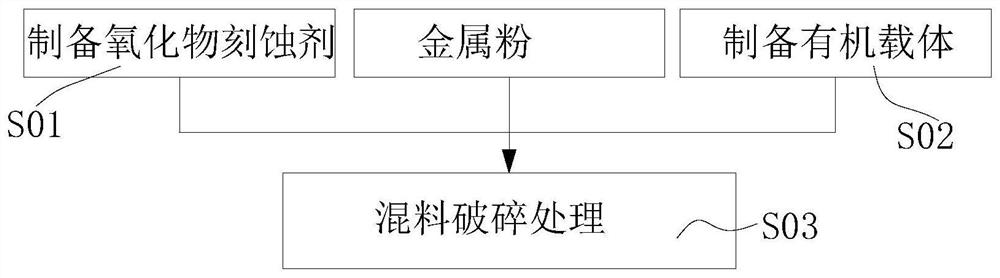

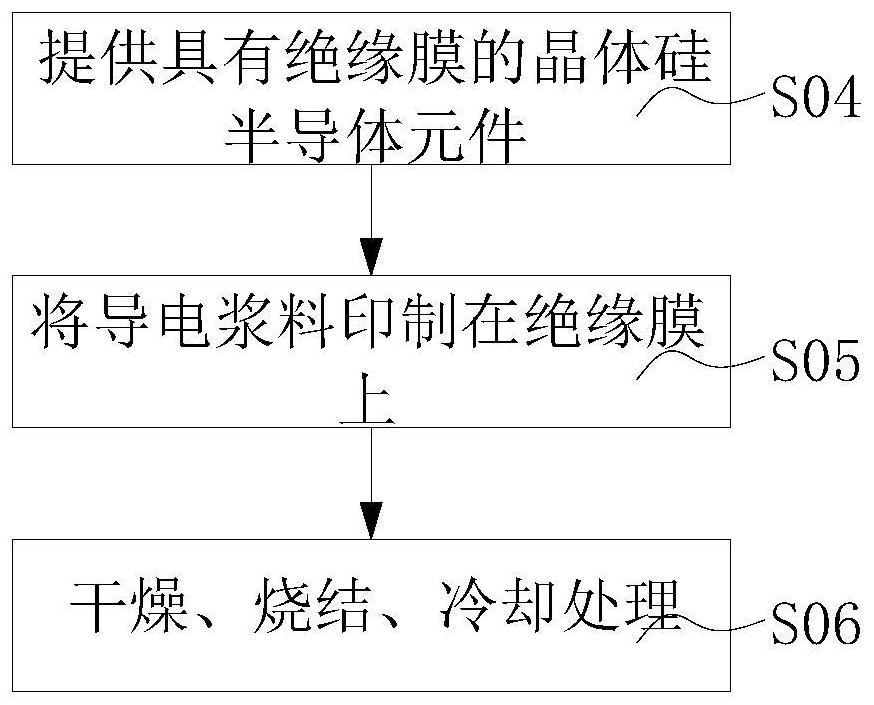

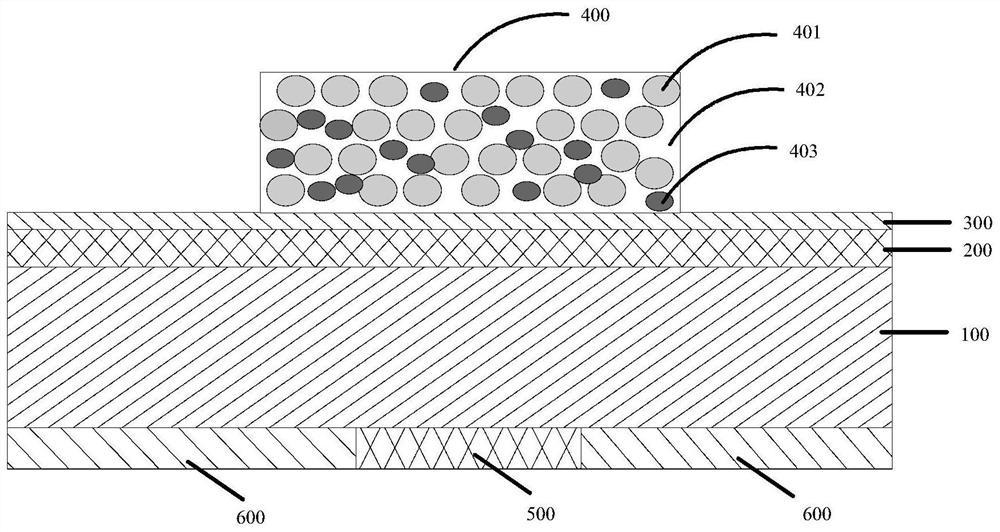

[0055] like figure 1 As shown, the preparation method of the front conductive paste of the crystalline silicon solar cell of the present invention comprises the following steps:

[0056] S01. The preparation steps of the oxide etchant are as follows: Weigh the oxide etchant raw material according to the ratio of raw materials mentioned above and mix them uniformly; put the uniformly mixed oxide etchant raw material into a heating furnace for heating to 900-1100°C, and keep warm at 900-1100°C for 60-180min to obtain a molten liquid oxide etchant; quench the molten liquid oxide etchant to obtain oxide etchant particles ; drying the oxide etchant particles at a temperature of 60-80° C.; crushing the dried oxide etchant particles to obtain oxide etchant powder with a particle size of 0.5-5.0 μm, Then place it in a drying oven and dry it at 80-100° C. to obtain dry oxide etchant powder.

[0057] Preferably, the quenching method is pouring the molten liquid oxide etchant into wate...

Embodiment 1

[0076] A front conductive paste for a crystalline silicon solar cell, calculated based on a total weight of 100 parts, comprises components in the following proportions: 88.5 parts of silver powder; 9.0 parts of an organic vehicle; and 2.5 parts of an oxide etchant.

[0077] Wherein, based on the weight of the oxide etchant as 100%, the following components are included:

[0078] Pb 3 o 4 6%, TeO 2 55%, Li 2 O 5%, SiO 2 20%, B 2 o 3 2.9%, Bi 2 o 3 2%, ZnO 3%, WO 3 1%, CuO 0.1%, P 2 o 5 5%.

[0079]The preparation method of the oxide etchant is as follows: Weigh the oxide etchant raw materials according to the above ratio and mix them uniformly; put the uniformly mixed oxide etchant raw materials into a heating furnace and heat to 1000°C, and keep warm at 1000°C for 120 minutes to obtain a molten liquid oxide etchant; pour the molten liquid oxide etchant into water at normal temperature (25°C) to cool to obtain oxide etchant particles; Place the oxide etchant...

Embodiment 2

[0087] A front conductive paste for a crystalline silicon solar cell, calculated based on a total weight of 100 parts, comprises components in the following proportions: 88.5 parts of silver powder; 9.0 parts of an organic vehicle; and 2.5 parts of an oxide etchant.

[0088] Wherein, based on the weight of the oxide etchant as 100%, the following components are included:

[0089] Pb 3 o 4 24%, TeO 2 20%, Li 2 O 11%, SiO 2 2%, B 2 o 3 9.9%, Bi 2 o 3 5%, ZnO 13%, WO 3 5%, CuO 10%, P 2 o 5 0.1%.

[0090] The preparation method of the oxide etchant is as follows: Weigh the oxide etchant raw materials according to the above ratio and mix them uniformly; put the uniformly mixed oxide etchant raw materials into a heating furnace and heat to 1000°C, and keep warm at 1000°C for 120 minutes to obtain a molten liquid oxide etchant; pour the molten liquid oxide etchant into water at normal temperature (25°C) to cool to obtain oxide etchant particles; Place the oxide et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com