Etching method of MXene material

A technology of chalcogen and nitrogen, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effect of promoting functional applications and large-scale preparation, and the preparation method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

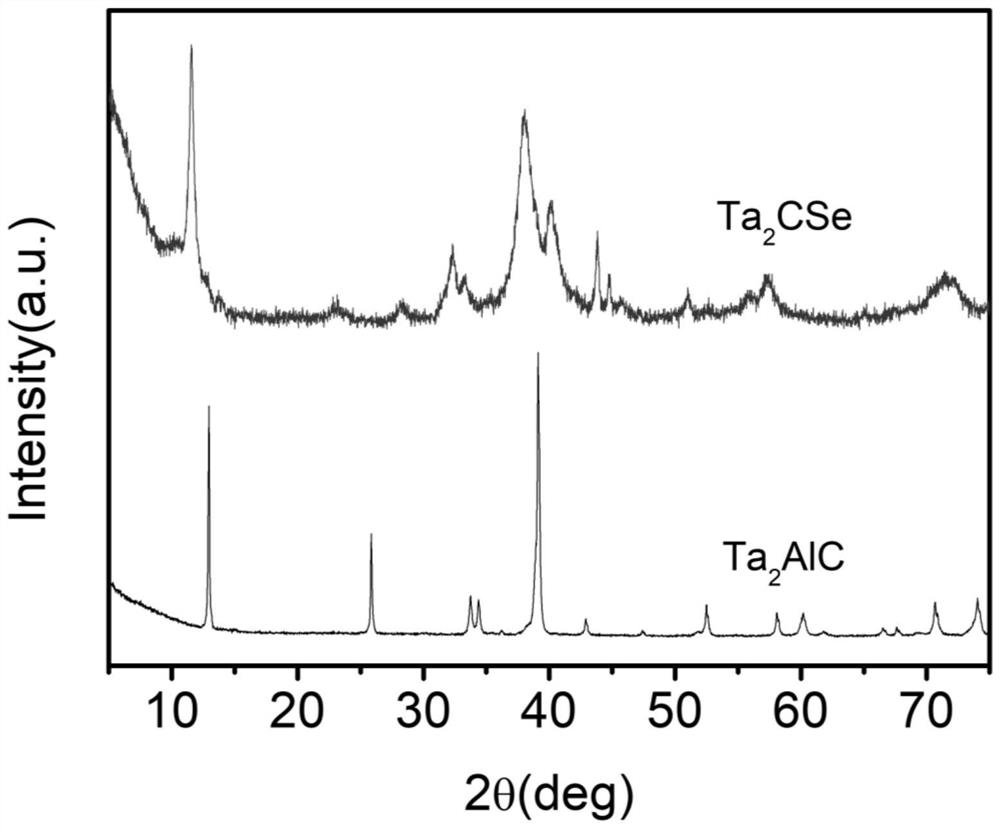

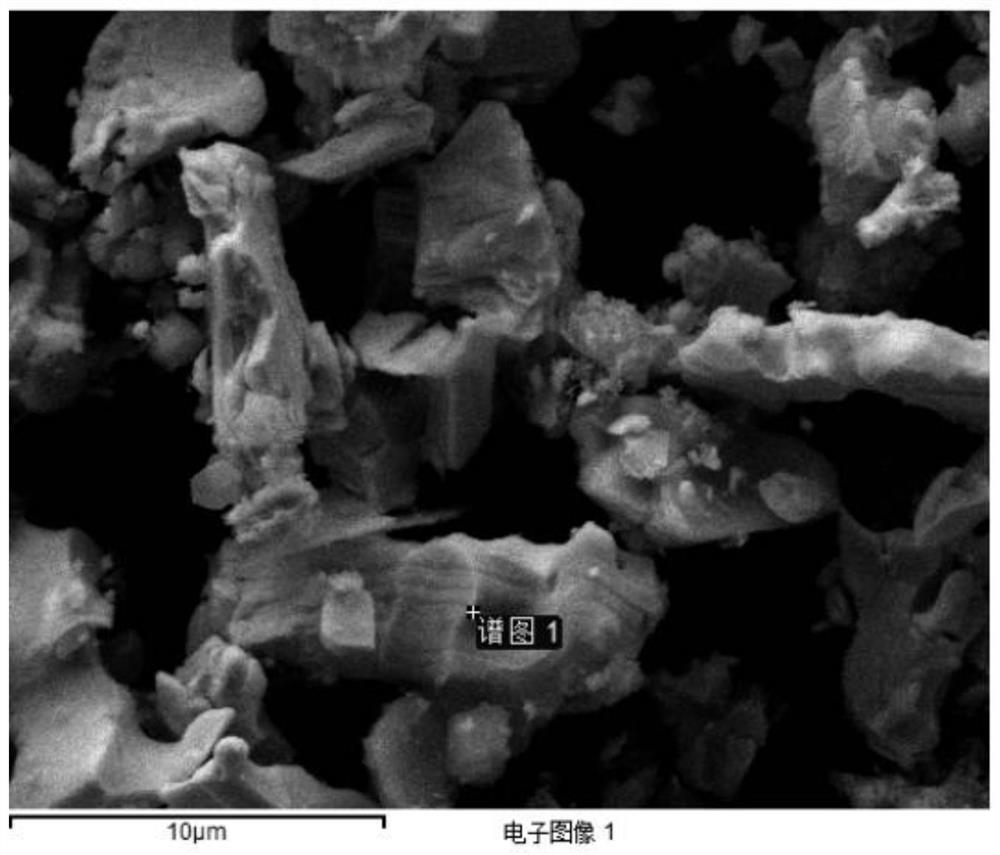

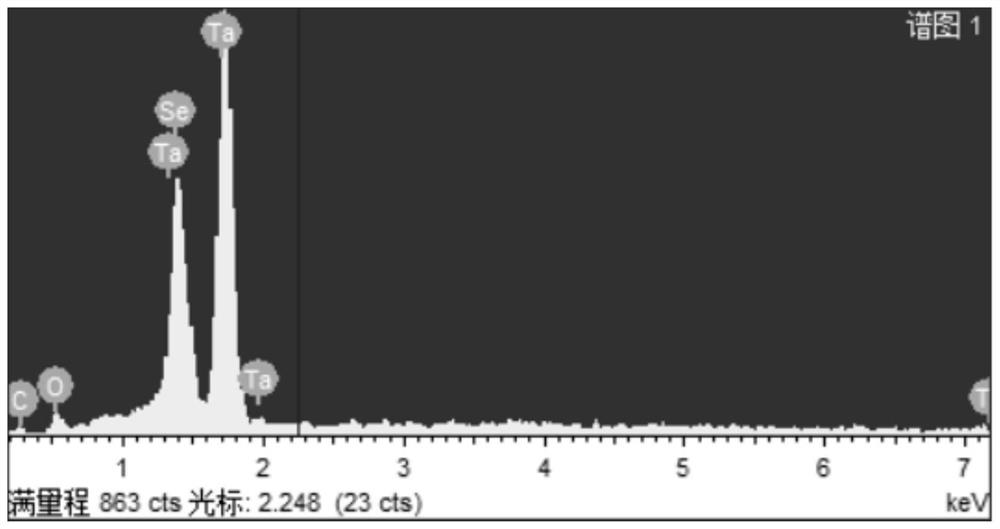

[0021] Embodiment 1: Preparation of MXene Ta 2 CSe powder

[0022] (1) Weigh Ta with a particle size of 500 mesh with a molar ratio of 1:1:5 2 AlC powder, NiSe powder, and LiCl are ground and mixed to obtain a mixture.

[0023] (2) Put the mixture into an alumina crucible, and then put it into a high-temperature vacuum tube furnace for reaction. The reaction conditions are: reaction temperature 650°C, holding time 5h, inert atmosphere protection. After the sintering temperature dropped to room temperature, the reaction product in the alumina crucible was taken out.

[0024] (3) Washing the reaction product with deionized water and alcohol: put the reaction product in a beaker, add deionized water, stir and ultrasonically clean for 30 minutes to wash off the remaining salt in the reaction product, and then carry out suction filtration. Put the reaction product obtained by suction filtration into an oven at 40° C., take it out after 12 hours, and obtain a powder product. fi...

Embodiment 2

[0025] Embodiment 2: Preparation of MXene Nb 2 CTe powder

[0026] (1) Weigh Nb with a molar ratio of 1:1:6:6 and a particle size of 500 mesh 2 AlC powder, Te powder, NaCl and KCl are ground and mixed to obtain a mixture.

[0027] (2) Put the mixture into an alumina crucible, and then put it into a high-temperature vacuum tube furnace for reaction. The reaction conditions are: reaction temperature 700°C, holding time 12h, inert atmosphere protection. After the sintering temperature dropped to room temperature, the reaction product in the alumina crucible was taken out.

[0028] (3) Washing the reaction product with deionized water and alcohol: put the reaction product in a beaker, add deionized water, stir and ultrasonically clean for 30 minutes to wash off the remaining salt in the reaction product, and then carry out suction filtration. Put the reaction product obtained by suction filtration into an oven at 40° C., take it out after 12 hours, and obtain a powder product....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com