Hole transport material based on silole fused heterocycle and preparation method and application of hole transport material

A hole transport material, fused heterocycle technology, applied in the field of hole materials, can solve the problems of high synthesis and preparation cost, poor stability of perovskite solar cells, limited wide-scale application, etc., to improve efficiency, enhance interfacial interaction, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

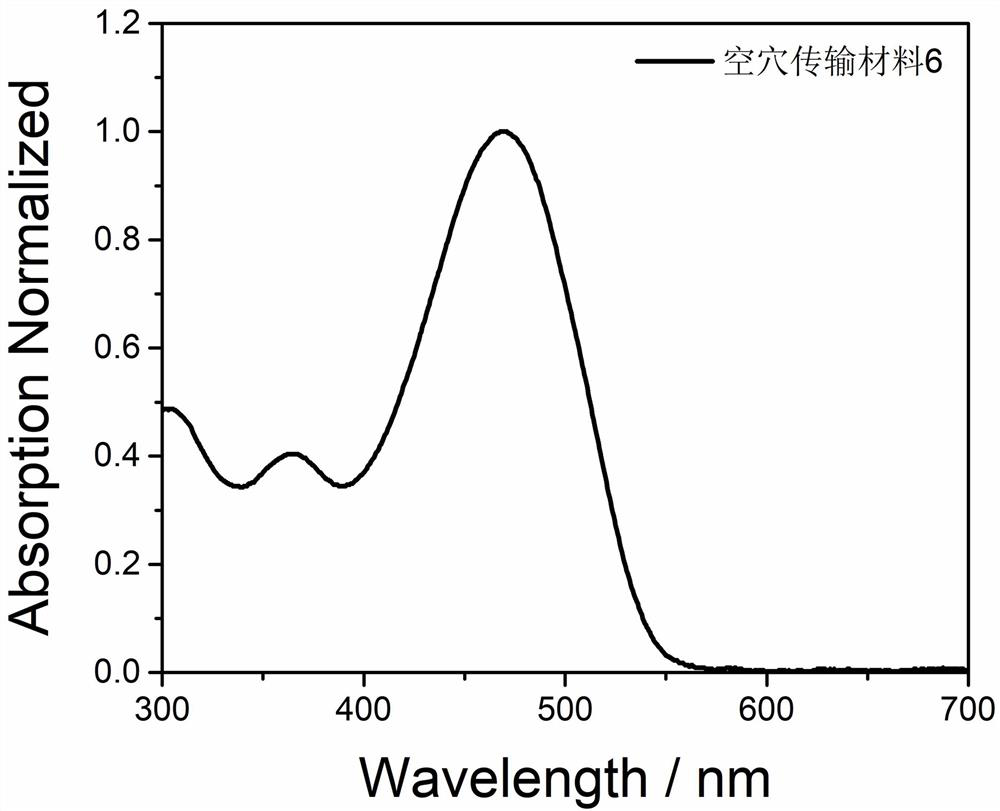

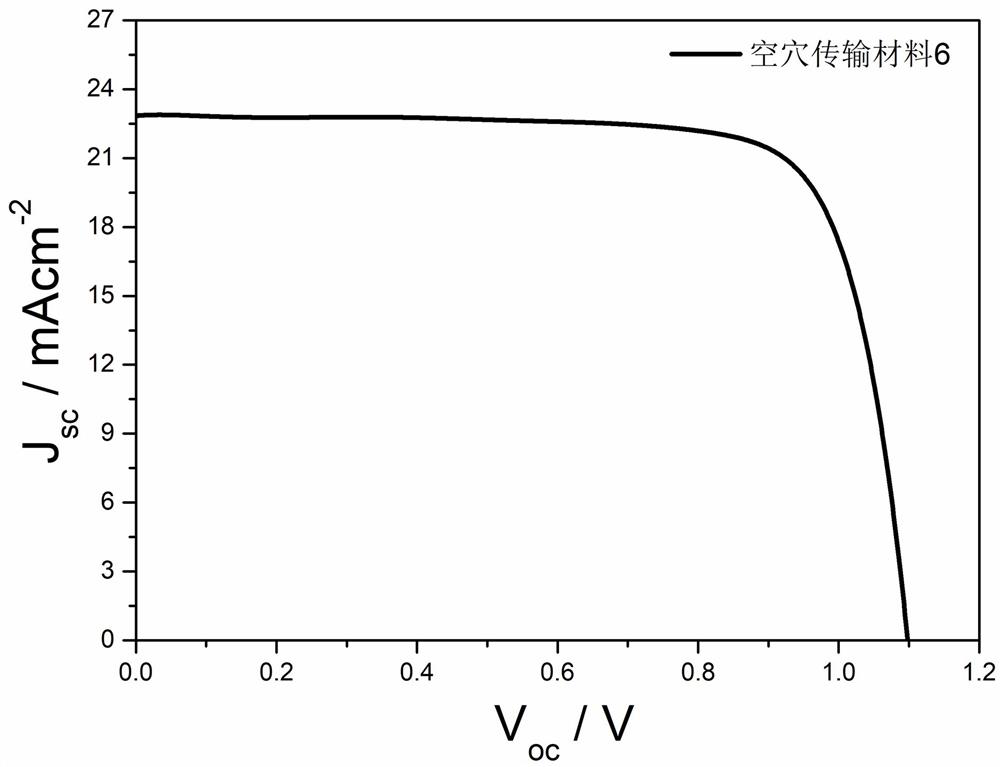

[0029] This embodiment provides a hole-transporting material based on a silole condensed heterocycle, the chemical formula of which is shown in formula (6):

[0030]

[0031] The preparation method of above-mentioned hole material (formula (6) compound) is as follows:

[0032] The compound of formula (1) used in this embodiment is according to literature Q.Yu, W.Fu, J.Wan, X.Wu, M.Shi, H.Chen.ACS Appl.Mater.Interfaces 6(2014)5798-5809. Prepared; the compound of formula (5) according to literature Y.-K.Peng, K.-M.Lee, C.-C.Ting, M.-W.Hsu, C.Y.Liu.J.Mater.Chem.A, 2019 ,7,24765-24770. Prepared; other reagents can be obtained through commercial means.

[0033] S1: make the compound of formula (1) and the compound of formula (2) undergo cyclization coupling reaction to generate the compound of formula (3);

[0034]

[0035] Specifically, this step is as follows: under the protection of argon, at a low temperature of -78°C, add 981 mg of the compound of formula (1) dissolved...

Embodiment 2

[0047] This embodiment is roughly the same as Embodiment 1, the main difference is:

[0048] S1: Synthesis of the compound of formula (3);

[0049] Under the protection of argon, under the condition of low temperature -78°C, add 981 mg of the compound of formula (1) dissolved in 30 mL of anhydrous tetrahydrofuran into a 100 mL eggplant-shaped reaction flask, and after 5 minutes of low temperature reaction, slowly add 1.56 mL of n-butyllithium ( 2.4mol / L), add 529mg of the compound of formula (2) after 1 hour of warm reaction, turn off the refrigeration, slowly return to room temperature; react for 8 hours. Water and ethyl acetate were added for extraction, the organic phase was dried over anhydrous magnesium sulfate, and the solvent was distilled off under reduced pressure to obtain 522 mg of the compound of formula (3). It is a yellow-green viscous liquid with a yield of 46%.

[0050] S2: Synthesis of the compound of formula (4);

[0051] Into a 100mL single-necked round-b...

Embodiment 3

[0055] This embodiment is roughly the same as Embodiment 1, the main difference is:

[0056] S1: Synthesis of the compound of formula (3);

[0057] Under the protection of argon, under the condition of low temperature -78°C, add 981 mg of the compound of formula (1) dissolved in 30 mL of anhydrous tetrahydrofuran into a 100 mL eggplant-shaped reaction flask, and after 5 minutes of low temperature reaction, slowly add 1.56 mL of n-butyllithium ( 2.4mol / L), add 794mg of the compound of formula (2) after warm reaction for 1h, turn off the refrigeration, slowly return to room temperature; react for 12h. Water and ethyl acetate were added for extraction, the organic phase was dried over anhydrous magnesium sulfate, and the solvent was distilled off under reduced pressure to obtain 749 mg of the compound of formula (3). It is a yellow-green viscous liquid with a yield of 66%.

[0058] S2: Synthesis of the compound of formula (4);

[0059] In a 100mL single-necked round-bottom fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| open-circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com