Gold nanoparticle-loaded cerium dioxide nanosheet material as well as synthesis method and application thereof

A technology of gold nanoparticles and ceria, applied in the field of nanomaterial preparation and carbon monoxide oxidation catalytic reaction, can solve the problem of difficulty in synthesizing two-dimensional ceria nanosheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

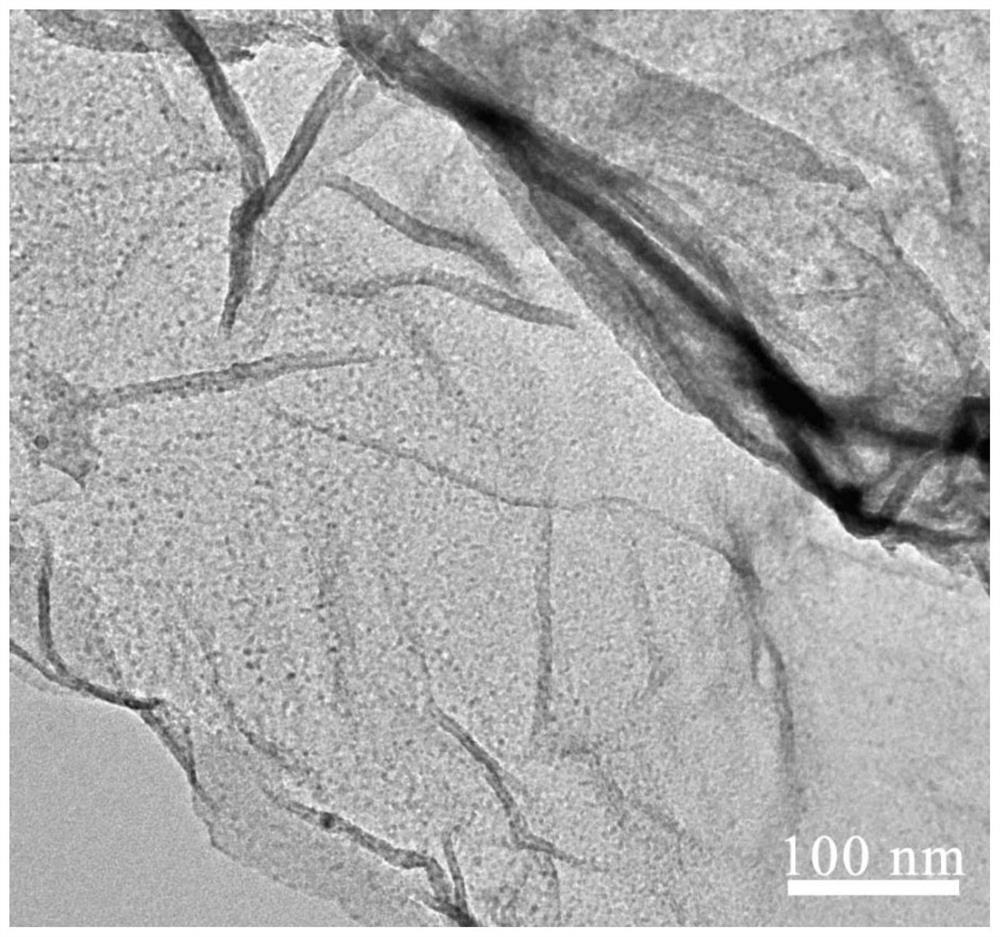

Image

Examples

Embodiment 1

[0042]A kind of synthetic method of gold nanoparticle loaded on ceria nano sheet material, can refer to figure 1 shown, including the following steps:

[0043] (1) Add 50mg graphene oxide into 50ml water, ultrasonically disperse evenly (the time is 15min), then add 2.5mmol cerium nitrate, stir and process (the time is 120min, the speed is 900r / min), centrifuge to take the precipitate (the speed is 9000r / min) min), washed 3 times with deionized water to obtain the precursor;

[0044] (2) Add the precursor described in step (1) into 15ml of water, and disperse evenly by ultrasonic (the time of ultrasonic is 20min), to obtain the precursor dispersion liquid, carry out freezing treatment with liquid nitrogen (time is 10-20s), at a temperature of Freeze-drying at -50°C for 3 days to obtain a dried product; heating the dried product for calcination treatment, the temperature of the calcination treatment was 400°C, the time of the calcination treatment was 2 hours, and the atmospher...

Embodiment 2

[0047] (1) Add 100mg graphene oxide into 50ml water, ultrasonically disperse evenly (time is 15min), then add 5mmol cerium nitrate, stir treatment (time is 120min, speed is 900r / min), centrifuge to take the precipitate (speed is 9000r / min ), washed 3 times with deionized water to obtain the precursor;

[0048] (2) Add the precursor described in step (1) into 15ml of water, and disperse evenly by ultrasonic (the time of ultrasonic is 20min), to obtain the precursor dispersion liquid, carry out freezing treatment with liquid nitrogen (time is 10-20s), at a temperature of Freeze-drying at -50°C for 3 days to obtain a dried product; the dried product was heated up for calcination treatment, the temperature of the calcination treatment was 400°C, the time of the calcination treatment was 4 hours, and the atmosphere of the calcination treatment was air atmosphere to obtain two Dimensional ceria nanosheets;

[0049] (3) Mix 675 μl polyvinyl alcohol solution (concentration is 0.5wt%)...

Embodiment 3

[0051] (1) Add 100mg graphene oxide into 50ml water, ultrasonically disperse evenly (the time is 15min), then add 2.5mmol cerium nitrate, stir and process (the time is 120min, the rotating speed is 900r / min), and the precipitate is collected by centrifugation (the rotating speed is 9000r / min) min), washed 3 times with deionized water to obtain the precursor;

[0052] (2) Add the precursor described in step (1) into 15ml of water, and disperse evenly by ultrasonic (the time of ultrasonic is 20min), to obtain the precursor dispersion liquid, carry out freezing treatment with liquid nitrogen (time is 10-20s), at a temperature of Freeze-drying at -50°C for 3 days to obtain a dried product; the dried product was heated up for calcination treatment, the temperature of the calcination treatment was 600°C, the time of the calcination treatment was 4h, and the atmosphere of the calcination treatment was air atmosphere, to obtain two Dimensional ceria nanosheets;

[0053] (3) Mix 675 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com