Miniature gas turbine with bearing embedded in motor

A micro gas turbine and gas turbine technology, which is applied in gas turbine installations, electrical components, machines/engines, etc., can solve problems such as vibration, unstable operation of rotor system, and limitation of the size of the rear of the rotating shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 Motor embedded bearing type micro gas turbine

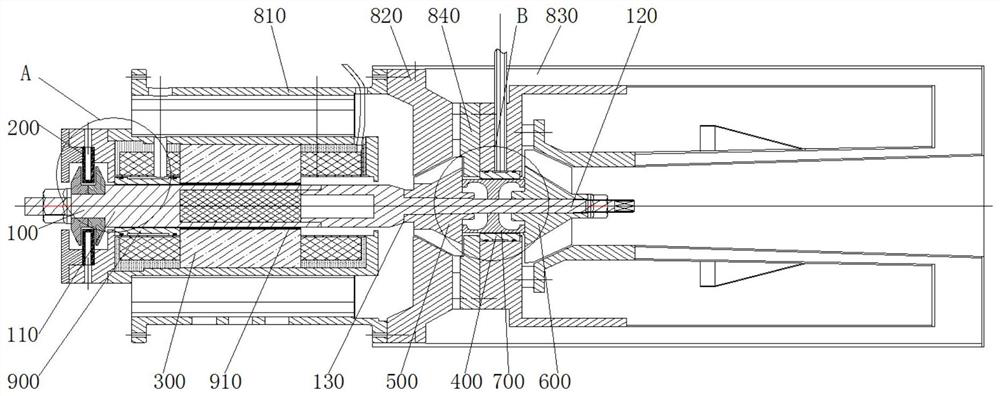

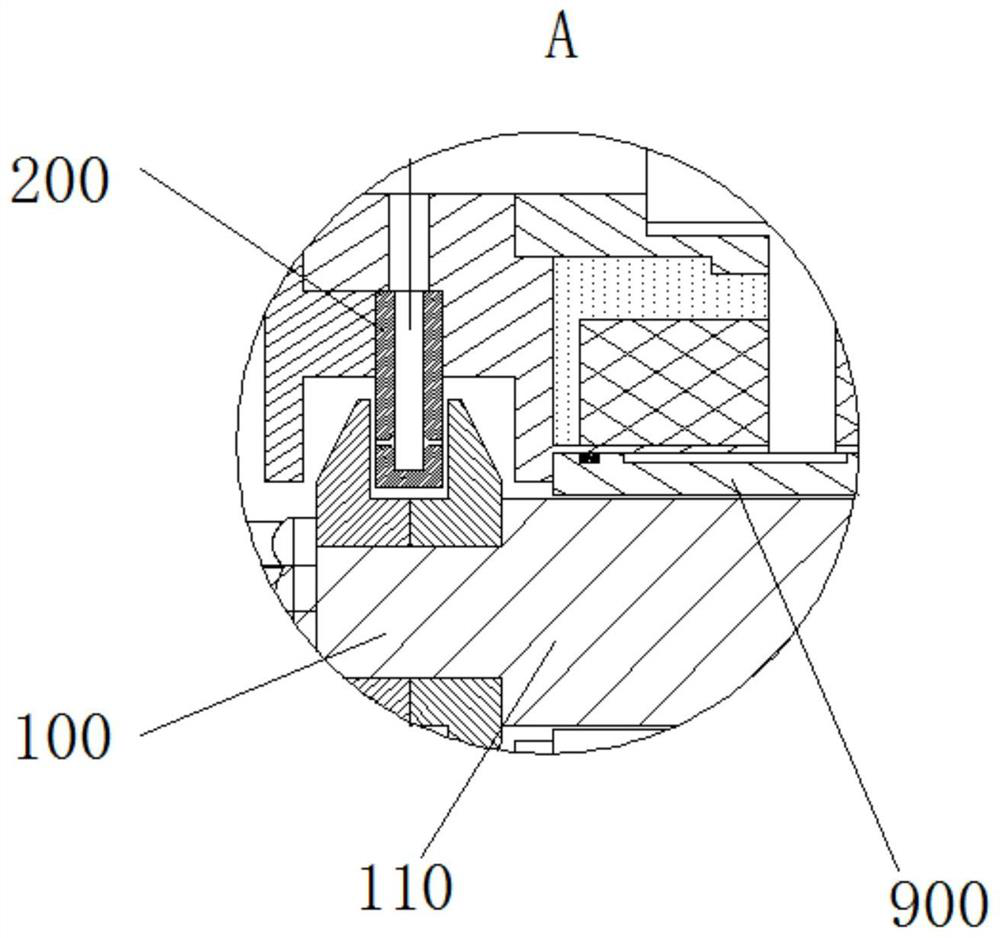

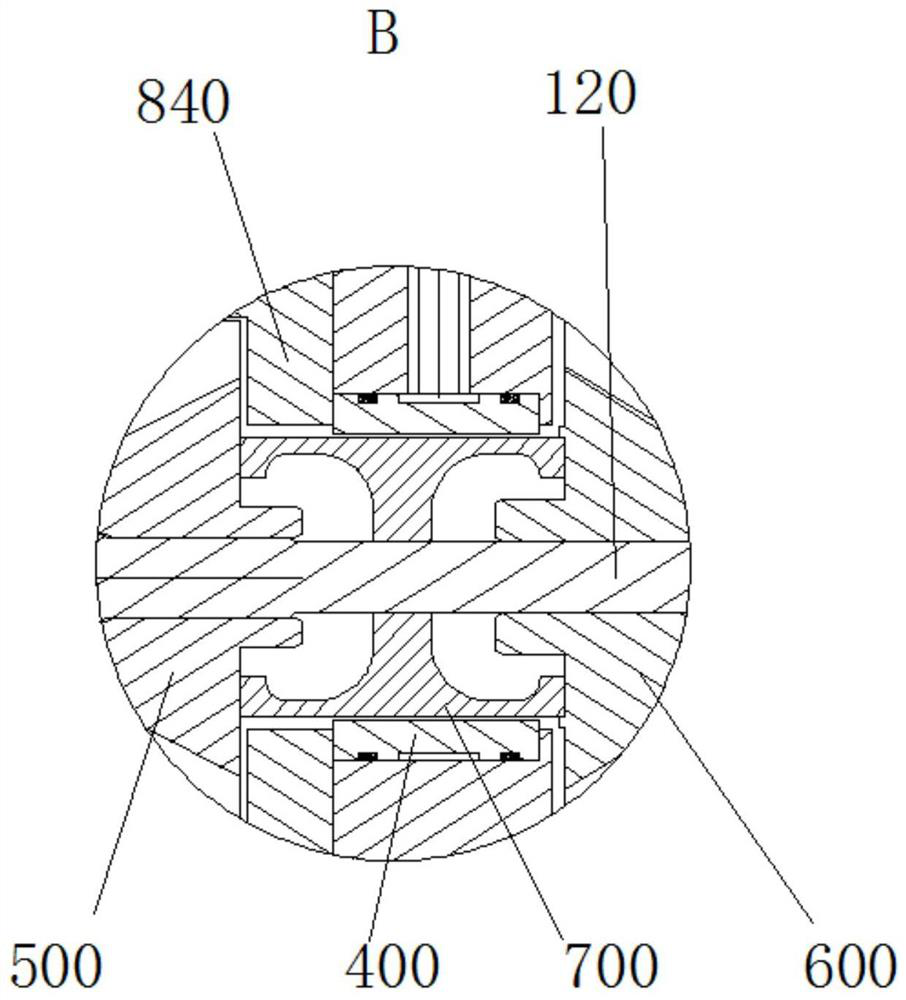

[0036] A bearing-embedded micro gas turbine with a motor, including a rotor system, a motor case 810, a gas turbine case 820 and a combustion chamber 830, such as figure 1 , figure 2 , image 3 shown.

[0037] The rotor system includes a rotating shaft 100. The rotating shaft 100 includes an integrally formed first shaft segment 110 and a second shaft segment 120. The diameter of the first shaft segment 110 is larger than the diameter of the second shaft segment 120. The first shaft segment 110 and the second shaft segment A step surface 130 is formed at the transition of 120; the thrust bearing 200, the first radial bearing 900 and the motor 300 are arranged in sequence on the first shaft section 110; the compressor 500 and the second radial bearing 400 are arranged in sequence on the second shaft section 120 and the turbine 600; one end of the compressor 500 abuts against the stepped surface 130; a third...

Embodiment 2

[0049] Embodiment 2 Motor built-in bearing type micro gas turbine

[0050] Same as Embodiment 1, the difference from Embodiment 1 is that: the cooperation relationship between the third bearing 910 and the motor 300 is as follows:

[0051] Such as Figure 5 As shown, the third bearing 910 is shrink-fitted in the motor 300 and tightly fitted with the motor 300. A part (such as a pin) to prevent circumferential rotation is provided between the motor 300 and the third bearing 910. One end is fixed in the motor 300, and the other end is fixed on the outer wall of the third bearing 910; there is a predetermined gap between the third bearing 910 and the rotating shaft 100, and the rotating shaft 100 is supported in the third bearing 910 by the air film in the predetermined gap; , the third bearing 910 is used as a radial bearing.

Embodiment 3

[0052] Embodiment 3 Motor built-in bearing type micro gas turbine

[0053] Same as Embodiment 2, the difference from Embodiment 2 is that the cooperation relationship between the third bearing 910 and the motor 300 is as follows:

[0054] exist Figure 5 On the basis of the matching relationship shown, a damper 911 is provided on the surface of the third bearing 910. The specific method is: at least one ring of rubber coating is provided around the outer wall of the third bearing 910, such as Image 6 , Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com