Method for extracting cephalotaxine from cephalotaxus hainanensis

A technology of harringtonine and crude torreya, applied in the field of harringtonine extraction, which can solve the problems of unfavorable industrial production, long consumption time and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

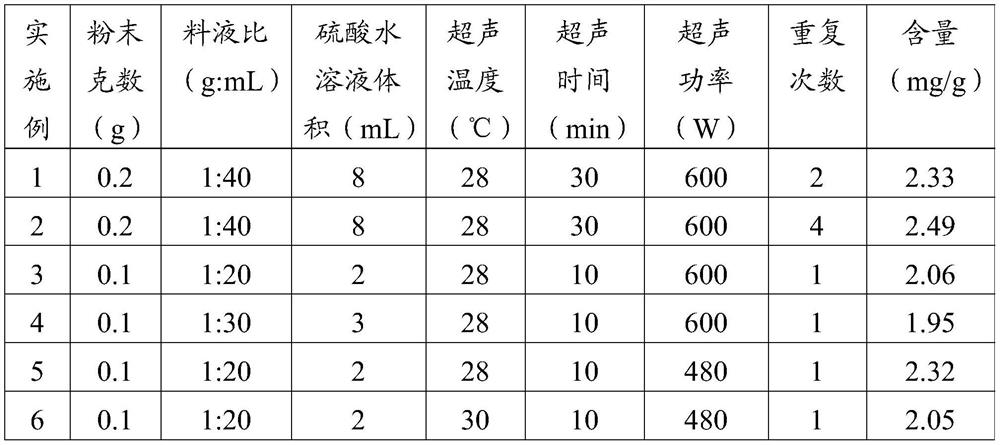

Embodiment 1

[0026] An embodiment of a method for extracting harringtonine from Hainan rough torreya provided by the present application, a method for extracting harringtonine from Hainan rough torreya, comprises the following steps:

[0027] Step 1. Crush the leaves of Torreya hainanensis and sieve for later use;

[0028] Step 2. Weigh the Hainan coarse torreya powder with a preset particle size and place it in a centrifuge tube, add an extraction solvent according to the preset material-to-liquid ratio, and then put it into an ultrasonic extraction device for ultrasonic extraction to obtain the first extraction solution, wherein, The extraction solvent is aqueous sulfuric acid;

[0029] Step 3. Put the first extraction solution into a centrifuge for centrifugation, pour out the supernatant after centrifugation, repeat the operation of adding extraction solvent, ultrasonic extraction, centrifugation, and pour out the supernatant after centrifugation for 1 to 4 times, and combine supernat...

Embodiment 2

[0035] A method for extracting harringtonine from Torreya hainanensis, comprising the following steps:

[0036] Step 1, after pulverizing the leaves of Torreya hainanensis, pass through a 10-mesh sieve;

[0037] Step 2. Weigh 0.2g Hainanese Torreya powder into a 15mL centrifuge tube, add 8mL sulfuric acid aqueous solution (pH=1) according to the ratio of solid to liquid at 1:40 for ultrasonic extraction, ultrasonic conditions: temperature is 28°C, time is 30min, the power is 600W, and the first extraction solution is obtained after the ultrasound is finished;

[0038] Step 3. Put the first extraction solution into a centrifuge device for centrifugation. Centrifugation conditions: speed 10000r / min, time 5min, pour out the supernatant after centrifugation, repeat adding extraction solvent, ultrasonic extraction, centrifugation, centrifugation end Finally, the supernatant was poured out for 4 times, and the supernatant obtained by each centrifugation was combined to obtain the s...

Embodiment 3

[0042] A method for extracting harringtonine from Torreya hainanensis, comprising the following steps:

[0043] Step 1, after pulverizing the leaves of Torreya hainanensis, pass through a 10-mesh sieve;

[0044] Step 2. Weigh 0.1g of Hainan Torreya hainanensis powder and place it in a 15mL centrifuge tube. Add 2mL of sulfuric acid aqueous solution (pH=1) for ultrasonic extraction according to the ratio of solid to liquid at 1:20. Ultrasonic conditions: temperature is 28°C, time is 10min, the power is 600W, and the first extraction solution is obtained after the end of ultrasound;

[0045] Step 3. Put the first extraction solution into a centrifuge device for centrifugation. Centrifugation conditions: speed 10000r / min, time 5min, pour out the supernatant after centrifugation, repeat adding extraction solvent, ultrasonic extraction, centrifugation, centrifugation end Finally, the supernatant was poured out once, and the supernatant obtained by each centrifugation was combined t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com