A kind of method for measuring coal tar three mixed naphthalene oil

A technology for coal tar and naphthalene oil, which is applied in the field of extraction of trimixed naphthalene oil, can solve problems such as backflow of external gas, and achieve the effects of easy cleaning, stable fractionation efficiency, and difficulty in sticking samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: take Maanshan Iron and Steel Coal Tar as an example, the method for measuring coal tar trimixed naphthalene oil comprises the following steps:

[0029] (1) take by weighing the coal tar that quality is 200.10g after dehydration;

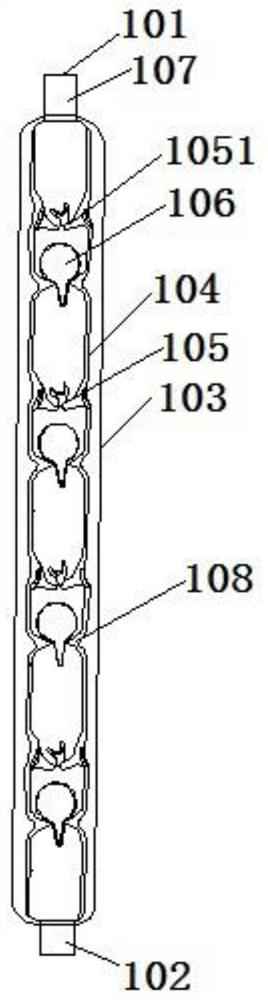

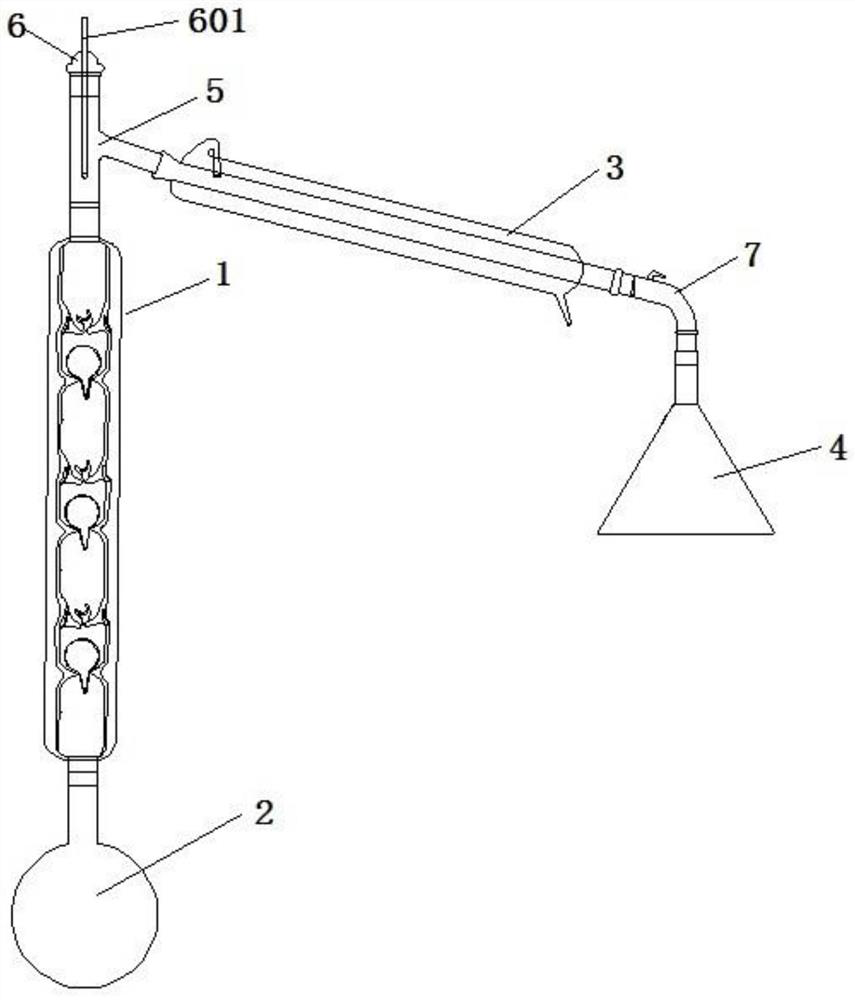

[0030] (2) Coal tar is put into the distillation bottle of fractionation unit, and fractionation unit is connected and assembled;

[0031] (3) start heating to the retort in step (2), cut off the cut temperature that is 180~250 ℃ and weigh the weight 32.87g of the cut and measure the purity to be 62.4%; cut off temperature in the described step (3) The specific steps for the fraction section of 180-250°C are: when the temperature reaches 180°C, replace the receiver of the fractionation device, and cut off the fraction section with a temperature of 180-250°C; when the temperature exceeds 250°C, replace the receiver again;

[0032] (4) Continue to heat the coal tar in the retort until crystallization occurs in the distillate, stop...

Embodiment 2

[0034] Embodiment 2: Take Maanshan Iron and Steel Coal Tar as an example, the method for measuring coal tar trimixed naphthalene oil comprises the following steps:

[0035] (1) take by weighing the coal tar that quality is 200.26g after dehydration;

[0036] (2) Coal tar is put into the distillation bottle of fractionation unit, and fractionation unit is connected and assembled;

[0037](3) start heating to the retort in step (2), cut off temperature and be the cut section of 180~250 ℃ and weigh the weight 33.04g of cut and measure purity to be 62%; Cut off temperature in described step (3) The specific steps for the fraction section of 180-250°C are: when the temperature reaches 180°C, replace the receiver of the fractionation device, and cut off the fraction section with a temperature of 180-250°C; when the temperature exceeds 250°C, replace the receiver again;

[0038] (4) Continue to heat the coal tar in the retort until crystallization occurs in the distillate, stop heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com