Polyester fiber screen mesh production device

A production device, polyester fiber technology, applied in the field of polyester fiber screen production device, can solve problems such as short service life, low production efficiency, melt deformity, etc., to improve wear resistance and thermal shock resistance , Avoid local defects, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

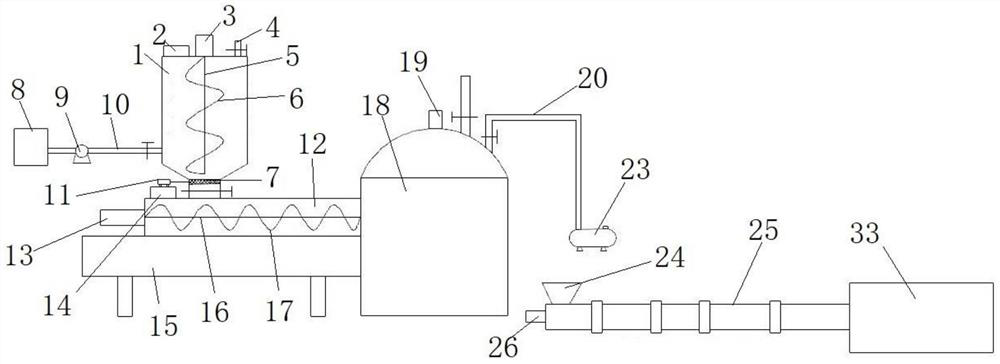

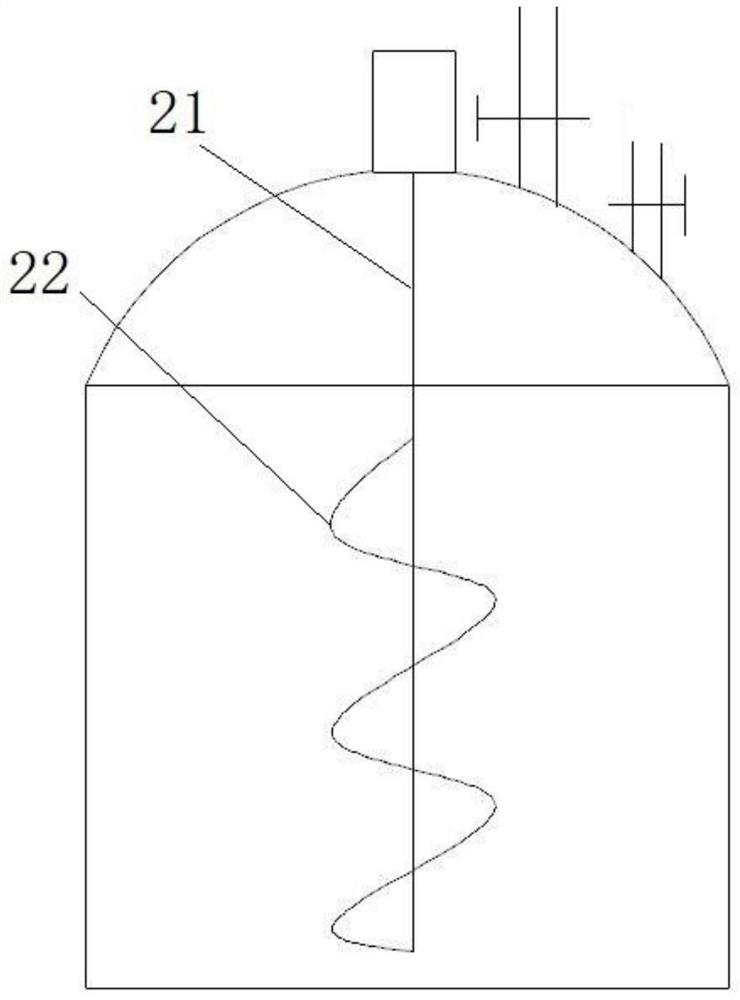

[0027] In this example, if figure 1 and figure 2 As shown, the heating pretreatment device includes a heating and polycondensation actuator for heating and polycondensing polyester chips under the protection of nitrogen, an air supply mechanism for feeding nitrogen into the heating and polycondensation actuator, and a heating and polycondensation actuator. The vacuum degassing mechanism for vacuum degassing the final polyester chips. Through the setting of the heating and polycondensation actuator, the polyester chips are heated and polycondensed, and the heating and polycondensation is carried out under the protection of nitrogen, so as to avoid impurity reactions and affect the effect of subsequent products. The setting of the air supply mechanism facilitates the delivery of nitrogen gas to the heating polycondensation actuator to ensure the supply demand of nitrogen gas. The setting of the vacuum defoaming mechanism facilitates vacuum defoaming of the polyester chips aft...

Embodiment 2

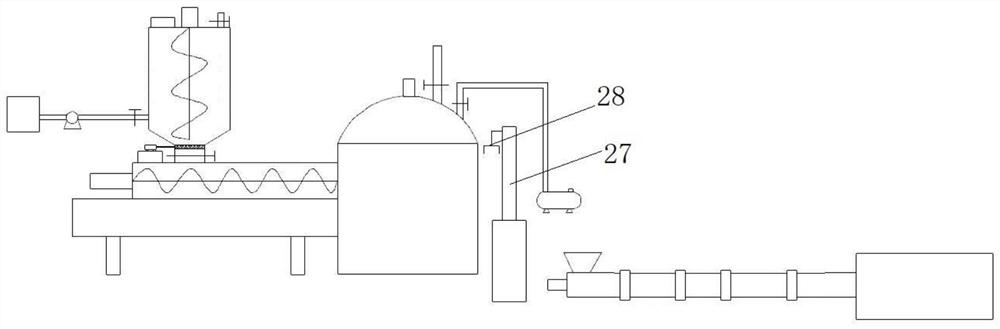

[0037] The difference between this embodiment and embodiment 1 is that, as image 3 and Figure 4 As shown, a column 27 is arranged between the defoaming tank and the barrel, and a manipulator 28 is arranged on the column, so as to facilitate taking out the defoamed polyester material and putting it into the hopper. The manipulator can perform actions such as rising, falling, swinging and rotating, which is convenient for flexible control to grab the polyester material and then put it into the feeding hopper. In order to facilitate the manipulator to grab garbage better and more flexibly, such as Figure 4 As shown, a base 29, a rotary driver 30 arranged on the base 29, a rotatable rotating seat 31 connected to the rotating driver 30, and a rotating seat 31 arranged on the rotating seat 31 for grabbing garbage can be provided at the front end of the manipulator. Jaw 32. The base is fixedly connected with the end effector of the manipulator. There are many forms of rotary d...

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 is that the defoaming tank is provided with a feed port connected to the outlet of the feed pipe, so that the polycondensed polyester can be directly introduced into the defoaming tank.

[0040] The molding device 33 includes an integral molding mold and a pouring pipe, the feed end of the pouring pipe is connected to the discharge end of the melting conveying device, and the discharge end of the pouring pipe is connected to the feed port of the forming mold. The polyester melt is poured into the molding die, and after being shaped by the molding die, it is demolded and taken out. Forming mold is as in the prior art, does not repeat too much here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com