A Hydrophobic Modified Black Talc Based Composite Pervaporation Membrane and Its Application

A pervaporation membrane and hydrophobic modification technology, which is applied in the field of hydrophobically modified black talc-based composite pervaporation membranes, can solve the problems of low selectivity and low flux, and achieve simple operation, improved separation performance and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation of black talc powder in the following examples:

[0030] 20 mL of acetone solvent was added to 1 g of Jiangxi Guangfeng black talc powder, and then ball-milled at 600 rpm for 6 hours, and then washed and dried to obtain 0.83 g of ultra-fine black talc powder. Through SEM observation, the longitudinal size of the black fossil is 200-1000 μm, and the thickness of a single black talc flake is 1-30 nm).

Embodiment 1

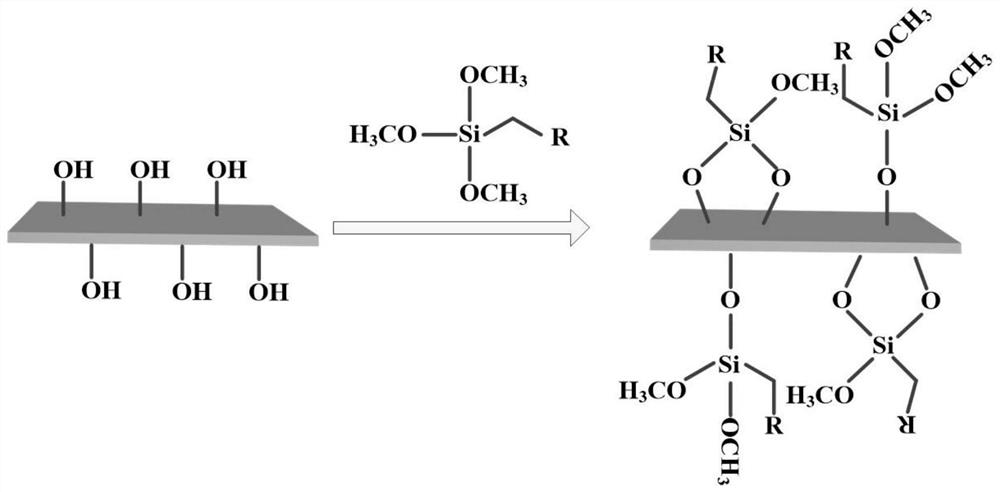

[0032] (1) Hydrophobically modified black talc powder: First, 0.1 g of ultra-fine Jiangxi Guangfeng black talc powder (200-1000 μm, the thickness of a single black talc flake is 1-30 nm) obtained by ball milling was ultrasonically dispersed in 100 mL of organic solvent n-hexane alkane to give 1 mgmL -1 60 mL of black talc dispersion was taken, then 2 mL of n-propyltrimethoxysilane was added to the above dispersion, and the reaction was stirred at 60 °C for 24 h; after the reaction was completed, the solvent hexane was used for washing and centrifugation , and dried at 60°C to obtain 0.0926g of hydrophobically modified black talc powder;

[0033] (2) Preparation of coating liquid: take 0.07624g of modified black talc powder and disperse it in a solvent 10mL of n-heptane by ultrasonic; then add 0.7624g of polydimethylsiloxane (PDMS), 0.0762g of ethyl orthosilicate and 0.0076g of dibutyltin dilaurate were stirred and reacted at room temperature for 4.5h, and then 9.2250g of coat...

Embodiment 2

[0038](1) Hydrophobically modified black talc powder: First, 0.1 g of ultra-fine Jiangxi Guangfeng black talc powder (200-1000 μm, the thickness of a single black talc flake is 1-30 nm) obtained by ball milling was ultrasonically dispersed in 100 mL of organic solvent n-hexane alkane to give 1 mgmL -1 60 mL of black talc dispersion was taken, then 2 mL of n-octyltrimethoxysilane was added to the above dispersion, and the reaction was stirred at 60 °C for 24 h; after the reaction was over, the solvent hexane was used for washing and centrifugation , and dried at 60°C to obtain 0.0958g of hydrophobically modified black talc powder;

[0039] (2) Preparation of coating liquid: take 0.0762g of modified black talc powder and disperse it in a solvent 10mL of n-heptane by ultrasonic; then add 0.7624g of polydimethylsiloxane (PDMS), 0.0762g of ethyl orthosilicate and 0.0076g of dibutyltin dilaurate were stirred and reacted at room temperature for 4.5h, and then 9.2250g of coating liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com