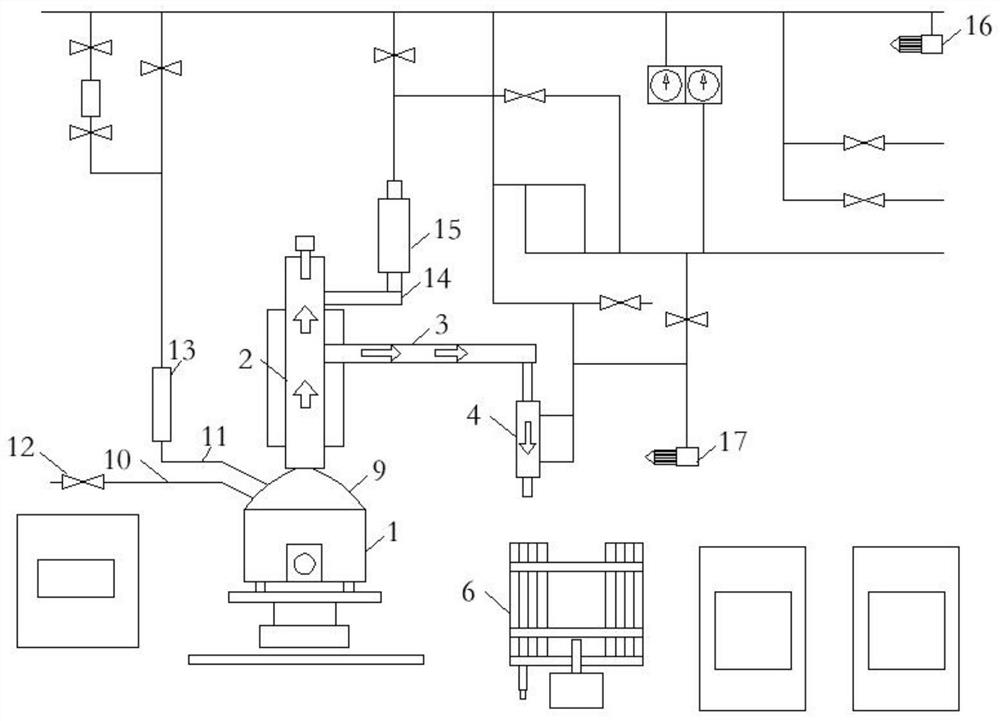

Distillation equipment capable of controlling temperature of condenser pipe and viscosity of fraction in real time and control method of distillation equipment

A technology for real-time control and distillation equipment, applied in the direction of distillation adjustment/control, boiler/distillate distillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The distillation sample is medium and low temperature coal tar from a certain factory;

[0033] A method for controlling the temperature of the condenser tube and the viscosity of the distillate, specifically comprising the steps of:

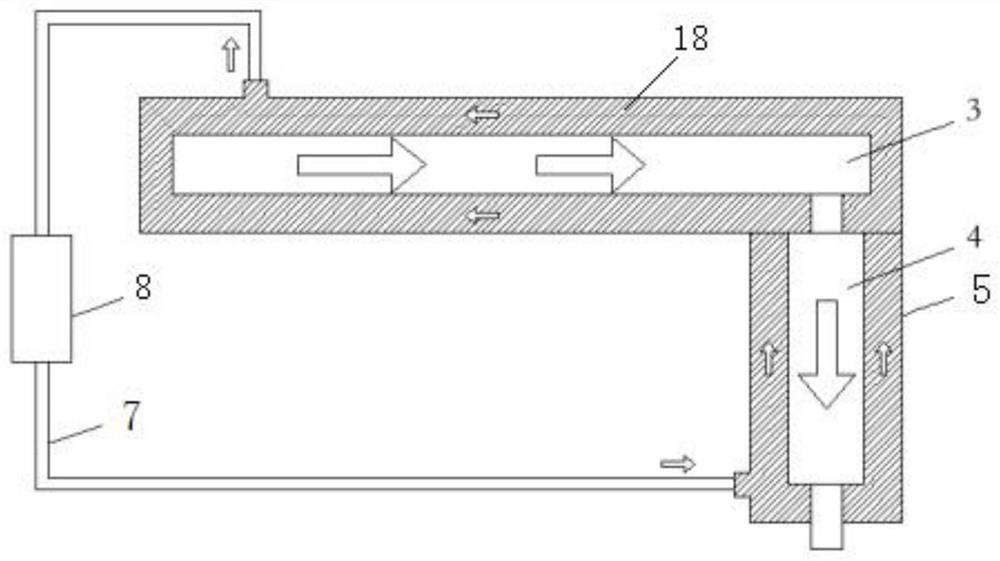

[0034] Step 1. According to the formula: Input the control variables k=1.5, b=10, c=15 in the circulating water bath control unit 8, and input the initial temperature of 20°C and the maximum limit temperature of 200°C, collect the measured viscosity value v of the viscosity sensor in the distillation process in real time, and calculate The theoretical circulation temperature T of the cold bath;

[0035] Step 2: 20°C is used as the starting temperature of the circulation temperature of the cold bath, and the circulating water bath control unit 8 compares in real time the current actually measured circulation temperature of the cold bath with the theoretical circulation temperature T of the cold bath obtained according to th...

Embodiment 2

[0038] Embodiment 2: the distillation sample is dehydrated crude oil of a certain plant;

[0039] A method for controlling the temperature of the condenser tube and the viscosity of the distillate, specifically comprising the steps of:

[0040] Step 1. According to the formula: Input the control variables k=2, b=15, c=10 in the circulating water bath control unit 8, and input the initial temperature of 20°C and the maximum limit temperature of 200°C, collect the measured viscosity value v of the viscosity sensor in the distillation process in real time, and calculate The theoretical circulation temperature T of the cold bath;

[0041] Step 2: 20°C is used as the starting temperature of the circulation temperature of the cold bath, and the circulating water bath control unit 8 compares in real time the current actually measured circulation temperature of the cold bath with the theoretical circulation temperature T of the cold bath obtained according to the formula of step 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com