Irradiation crosslinking flexible corrosion-resistant low-smoke halogen-free composition as well as preparation method and application thereof

A flexible and corrosion-resistant technology, applied in the field of cable preparation, radiation cross-linking flexible corrosion-resistant low-smoke halogen-free composition, can solve the problem of reducing the reliability and safety of charging cables, affecting the life and performance of charging cables, Affect the performance of cable materials and other issues to achieve the effect of improving thermal aging and service life, promoting compatibility, and improving mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

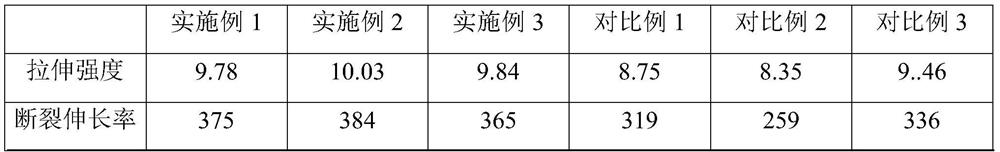

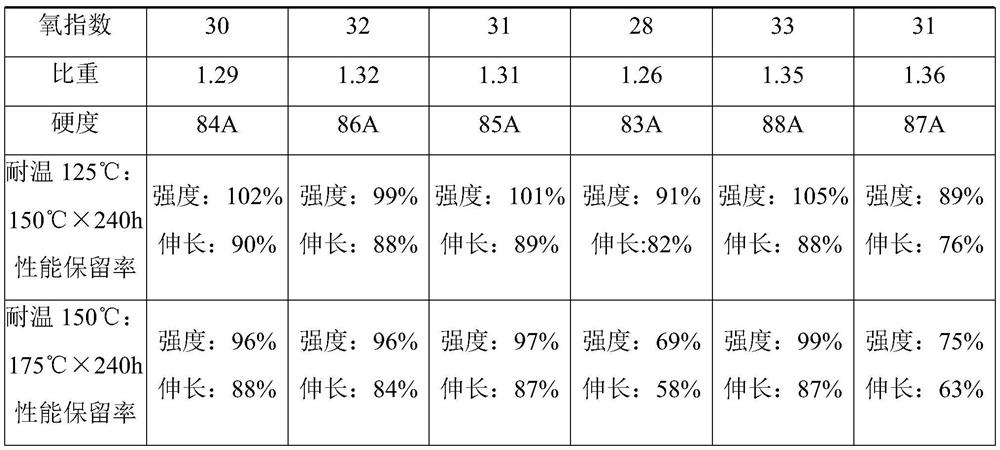

Examples

Embodiment 1

[0015] This embodiment provides a radiation-crosslinked flexible, corrosion-resistant, low-smoke and halogen-free composition. The raw material composition of the radiation-crosslinked, flexible, corrosion-resistant, low-smoke and halogen-free composition includes: Thickening agent of 15 parts by weight, super-tough elastomer of 20 parts by weight, chemical method surface treatment magnesium hydroxide of 50 parts by weight, coupling auxiliary agent of 1.5 parts by weight, antioxidant of 6 parts by weight, 3 parts by weight The crosslinking agent of part, the lubricant of 6 parts by weight.

[0016] The toughening agent is a mixed compatibilizer of ethylene propylene rubber and POE. The super-tough elastomer is Mitsui's DF series elastomer DF640. The coupling aid is silane coupling agent 172. Antioxidant is bisphenol antioxidant. The crosslinking agent is TAIC. The lubricant is silicone.

[0017] This embodiment also provides a preparation method of the above-mentioned rad...

Embodiment 2

[0020] This example provides a radiation-crosslinked flexible, corrosion-resistant, low-smoke and halogen-free composition. The difference from Example 1 is that the raw material composition of the radiation-crosslinked, flexible, corrosion-resistant, low-smoke and halogen-free composition includes: 10 parts by weight of ethylene vinyl acetate copolymer, 10 parts by weight of toughening agent, 15 parts by weight of super tough elastomer, 40 parts by weight of chemical surface treatment magnesium hydroxide, 0.7 parts by weight of coupling aid, 3 parts by weight The antioxidant of part, the crosslinking agent of 2 parts by weight, the lubricant of 4 parts by weight.

Embodiment 3

[0022] This example provides a radiation-crosslinked flexible, corrosion-resistant, low-smoke and halogen-free composition. The difference from Example 1 is that the raw material composition of the radiation-crosslinked, flexible, corrosion-resistant, low-smoke and halogen-free composition includes: 12 parts by weight of ethylene vinyl acetate copolymer, 13 parts by weight of toughening agent, 18 parts by weight of super tough elastomer, 45 parts by weight of chemical surface treatment magnesium hydroxide, 1.0 parts by weight of coupling aid, 4 parts by weight The antioxidant of part, the crosslinking agent of 2.5 parts by weight, the lubricant of 5 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com