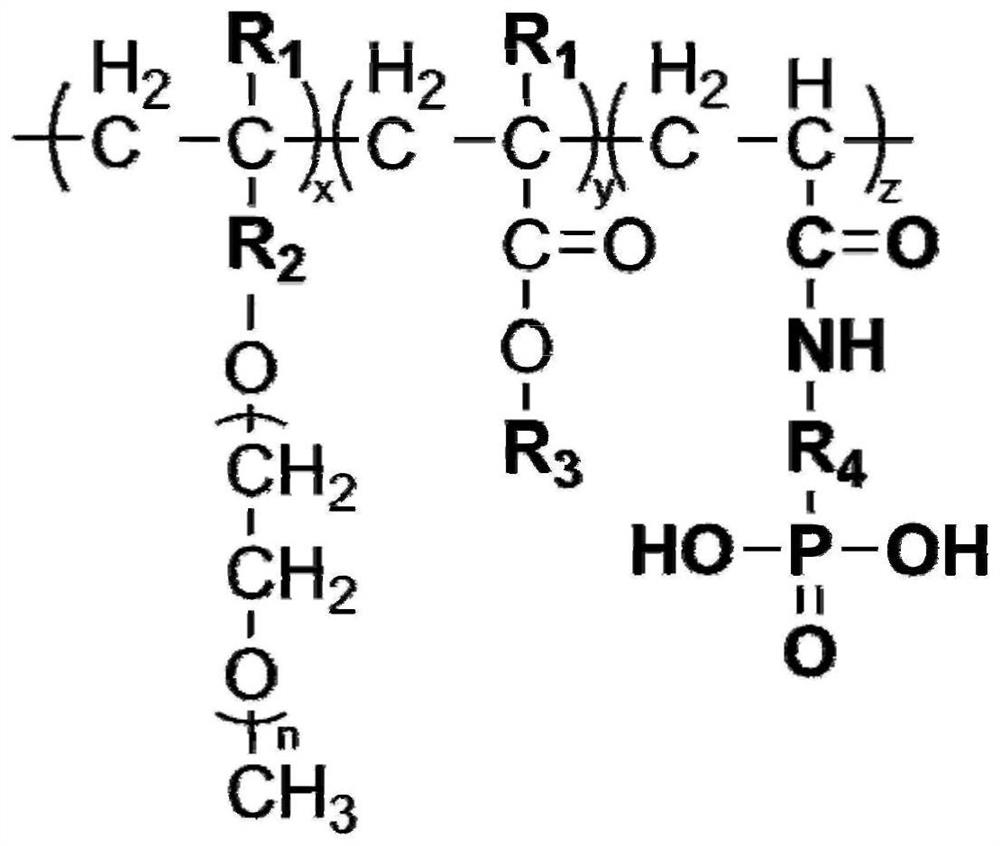

Phosphate-containing high-adaptability early-strength polycarboxylate superplasticizer, and preparation method and application thereof

An early-strength, polycarboxylic acid technology, applied in the field of high-adaptation early-strength polycarboxylate water reducer and its preparation, can solve the problems of low early strength of concrete, avoid incompatibility problems and achieve good compatibility , The effect of preparation technology is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A highly adaptable early-strength polycarboxylate water reducer containing phosphate, prepared by the following method:

[0038] 1) The first feeding: mix 810g water and 90g allyl polyoxyethylene ether (M n =1500g / mol) into the reactor, stir to obtain the mass concentration of 10% allyl polyoxyethylene ether aqueous solution, and then add 0.5g mass concentration of 25% hydrogen peroxide to control the temperature of the reactor at 15°C;

[0039] 2) The second feeding: start to add dropwise the mixed solution of 10g acrylic acid and 10g water, then start to add dropwise 6g mixed aqueous solution containing 0.1g sodium formaldehyde sulfoxylate and 0.5g thioglycolic acid in 2 minutes, then start within 10 minutes Add 30 g of a mixed aqueous solution containing 3 g of 2-acrylamido-ethyl phosphoric acid dropwise, the entire dropping time lasts for 2.0 hours, and continue to mature for 0.5 hours after the dropping;

[0040] 3) Product preparation: After the polymerization r...

Embodiment 2

[0042] A highly adaptable early-strength polycarboxylate water reducer containing phosphate, prepared by the following method:

[0043] 1) Feeding for the first time: mix 538g water and 95g isobutylene polyoxyethylene ether (M n =2000g / mol) joins in the reaction kettle, obtains the isobutylene polyoxyethylene ether aqueous solution that mass concentration is 15% after stirring, and then one-time addition of 0.6g mass concentration is 25% sodium persulfate, and the control reaction kettle temperature is 17 ℃;

[0044] 2) The second feeding: start dropwise adding the mixed solution of 13g sodium acrylate and 13g water, then start dropwise adding 8g mixed aqueous solution containing 0.2gL-ascorbic acid and 0.6g mercaptopropionic acid in 3 minutes, then start dropwise adding within 25 minutes 10g mixed aqueous solution containing 1g of 2-acrylamido-propylphosphoric acid, the entire dropping time lasts for 2.5 hours, and the aging is continued for 1.0 hour after the dropping;

[...

Embodiment 3

[0047] A highly adaptable early-strength polycarboxylate water reducer containing phosphate, prepared by the following method:

[0048] 1) Feeding for the first time: mix 233g water and 100g butyl polyoxyethylene ether (M n =3000g / mol) joins in the reaction kettle, obtains mass concentration after stirring evenly and is the butyl polyoxyethylene ether aqueous solution of 30%, then one-time addition of 0.8g mass concentration is 25% potassium persulfate, controls the reaction kettle temperature at 30°C;

[0049] 2) Feeding for the second time: start to add dropwise the mixed solution of 14g methacrylic acid and 14g water, then start to add dropwise 11g mixed aqueous solution containing 0.3g sodium bisulfite and 0.8g sodium methacrylate sulfonate in 4 minutes, then Start to add 30 g of mixed aqueous solution containing 3 g of 2-acrylamido-butylphosphoric acid dropwise within 30 minutes, the whole dropping time lasts for 3.0 hours, and continue to ripen for 1.5 hours after the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com