Portland cement preparation method

A technology of Portland cement and calcium silicate, applied in the field of cement, can solve the problems of reduced grinding effect, weakened impact force of steel balls, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

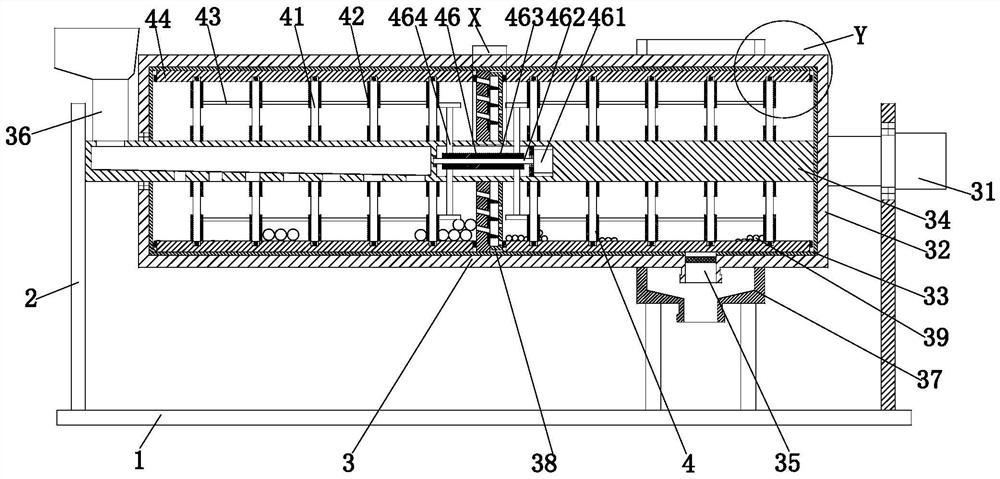

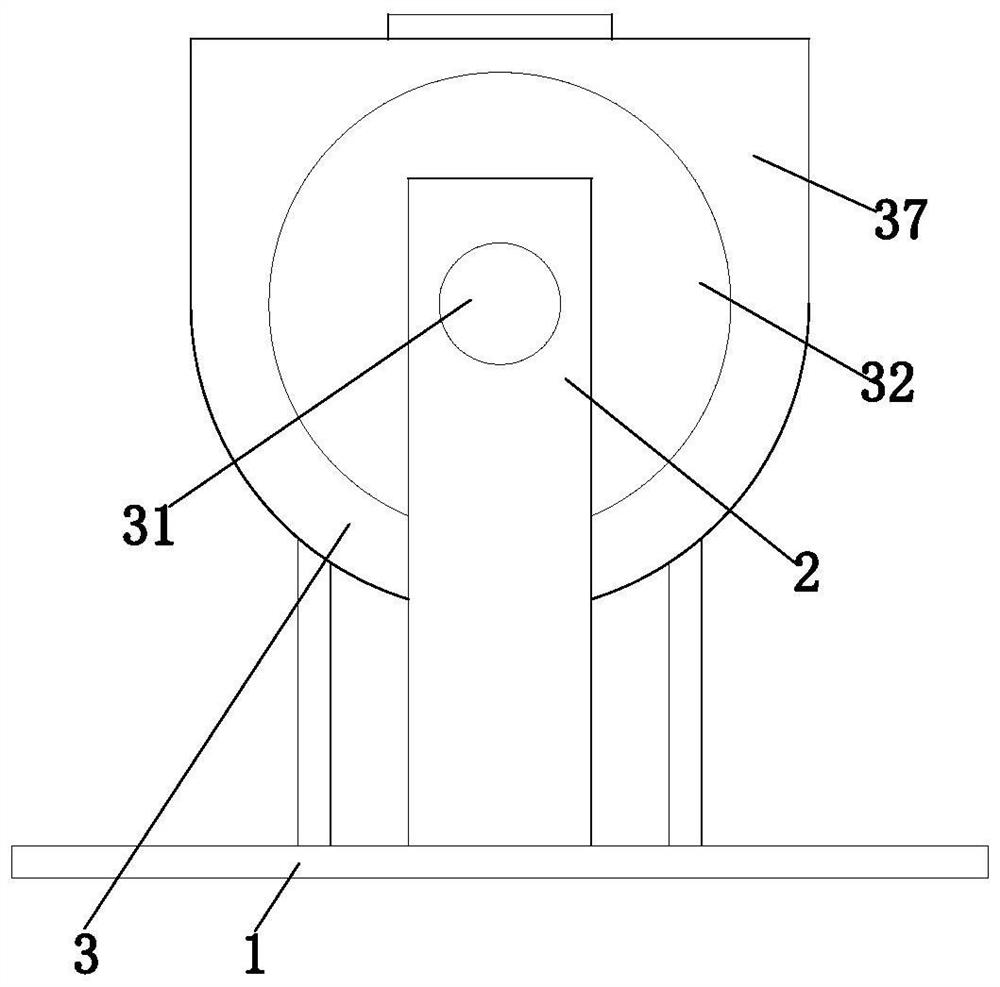

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

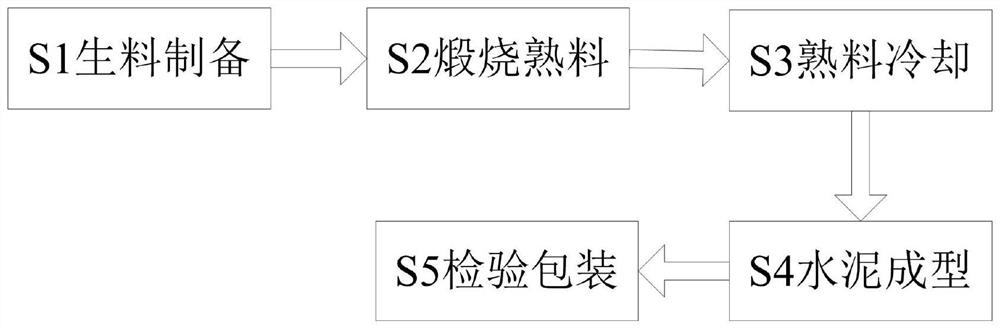

[0038] like Figure 1 to Figure 9 As shown, a method for preparing Portland cement, which uses a ball mill, the ball mill includes a bottom plate 1, a mounting plate 2, a grinding device 3 and a wall scraping device 4, and the specific method when using the above ball mill to prepare Portland cement The process is as follows:

[0039] S1. Raw material preparation: After the limestone and clay are crushed by a crusher, they are finely ground into powder by a ball mill according to the proportion;

[0040] S2. Calcination of clinker: send the powder obtained after S1 treatment into a cement rotary kiln to be calcined to a molten state to obtain the required calcium silicate clinker;

[0041] S3. Clinker cooling: use a cement clinker cooler to cool t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com