PET product machining system and machining method

A processing system and product technology, applied in the field of PET, can solve the problems of cumbersome operation, affecting the appearance of products, unclean product surface, etc., to achieve the effect of easy operation and clean product surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

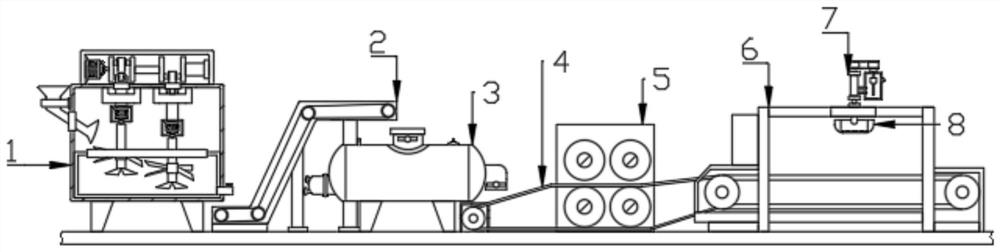

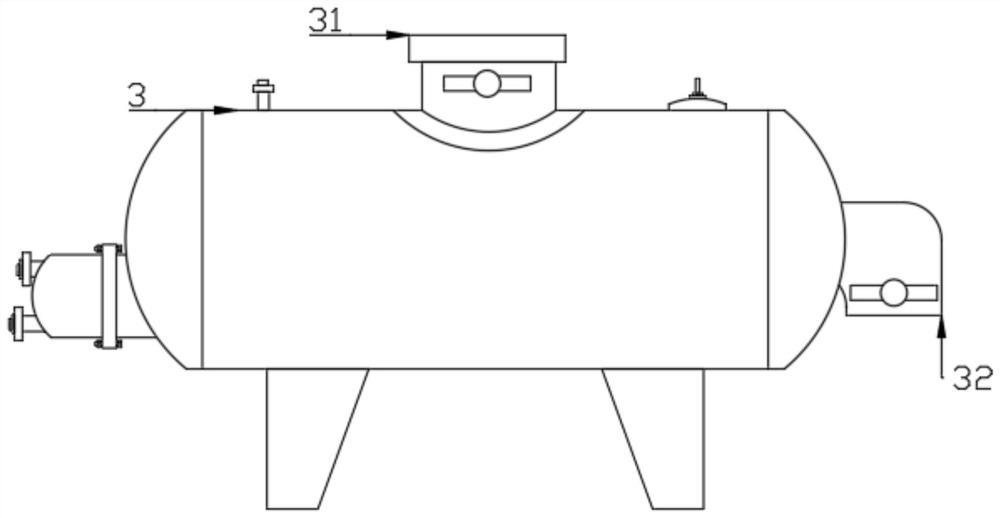

[0040]Example 1, referring to attachmentFigure 1 - Figure 6, The present invention provides a PET product processing system and a processing method thereof, including a pulverizing device 1, a transport table 2, a heating furnace 3, a transmission belt 4, a rolling device 5, a cooling transmission station 6, a water spray device 7, and a nozzle device. 8;

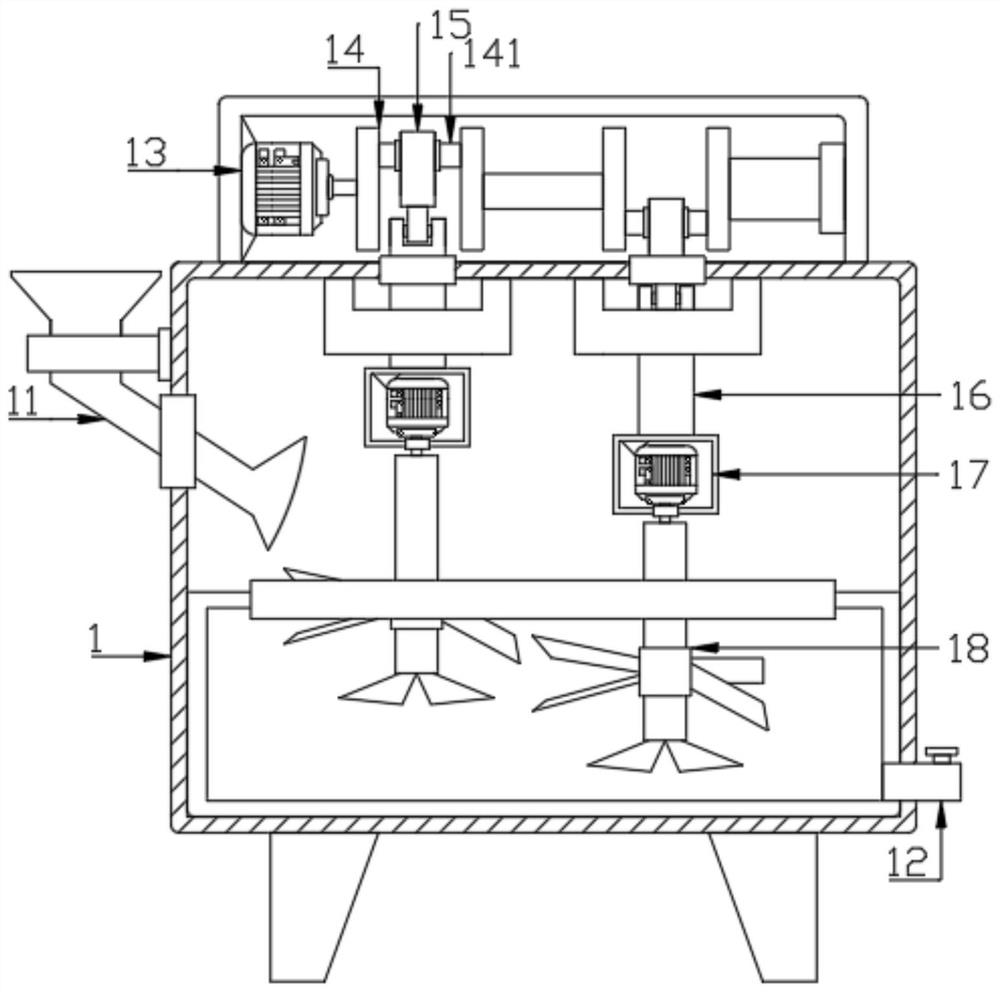

[0041]Further, the crushing device 1 is provided with a transport stage 2, the pulverizer 1 includes a pulverized feed opening 11, a pulverizing discharge opening 12, a drive motor 13, a turntable 14, a connecting rod 15, a shaft 16, a rotary electric machine 17, and a pulverized stirring The rod 18, specifically, the left end of the pulverizer 1 is provided with a pulverized feed port 12, and the pulverizing apparatus 1 is provided on the right side of the pulverizing apparatus 1, the upper left side of the pulverizer 1 is fixed to the left side, the drive motor 13 output Connecting the turntable 14, the inside of the turntable 14 ...

Embodiment 2

[0046]Example 2, reference attachmentFigure 7 , A PET product processing system provided by the present invention and a processing method thereof, including a nozzle device 8;

[0047]Further, the nozzle device 8 is threaded to the bottom end of the water spray device 7, and the nozzle device 8 includes a square spray head 82, in particular, the square nozzle 82 is threaded and connected to the bottom end of the water spray device 7, and threaded through square nozzle 82 7 The bottom of the 7 is fixed to achieve the effect of uniform water sprinkling in the air pump 71 in the upper end of the solid PET;

[0048]The use process of the present invention is as follows: By placing the PET product in the bottom end of the pulverizer 1 by the pulverizing feed port 11, the rotary electric machine 17 is pulverized by activating the drive motor 13 and the rotary electric machine 17, so that the rotary electric machine 17 will drive the rotary electric machine 17. Turn, cause the PET product in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com