A CNC machining center capable of clamping special-shaped workpieces

A technology of special-shaped workpiece and machining center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

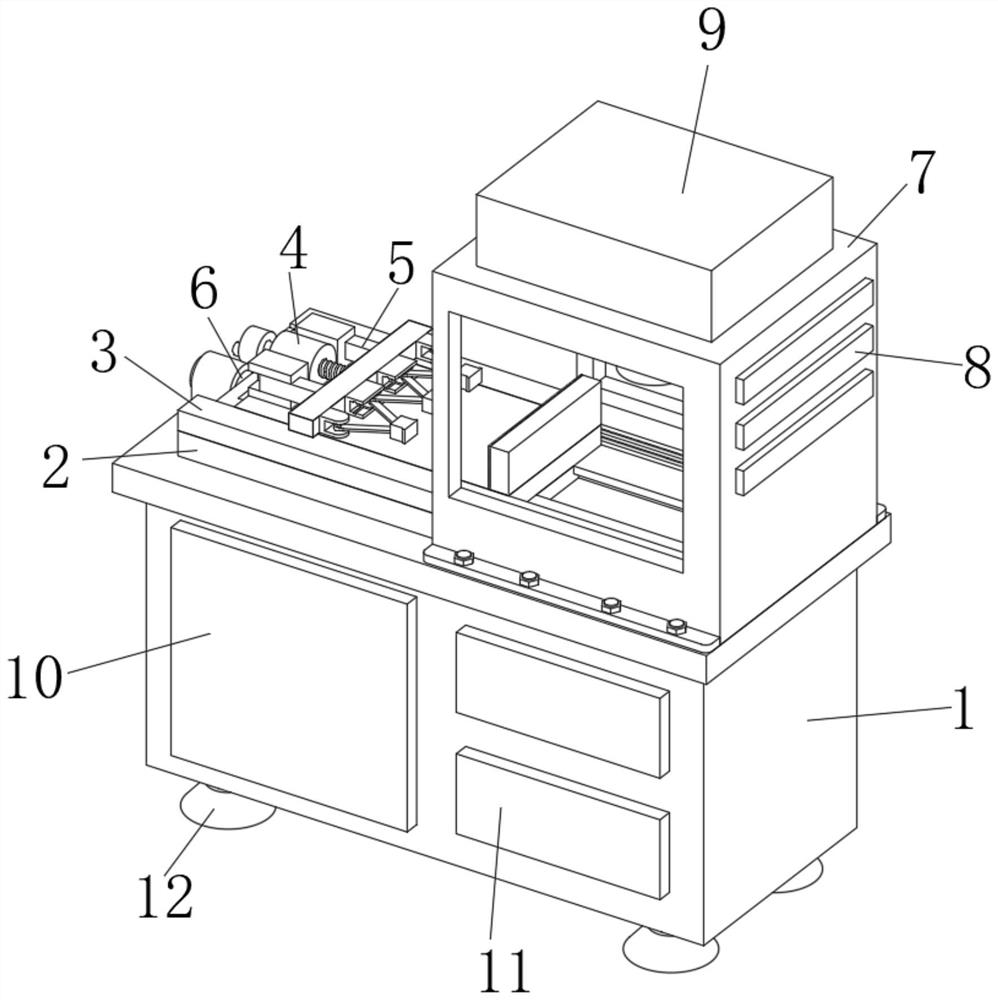

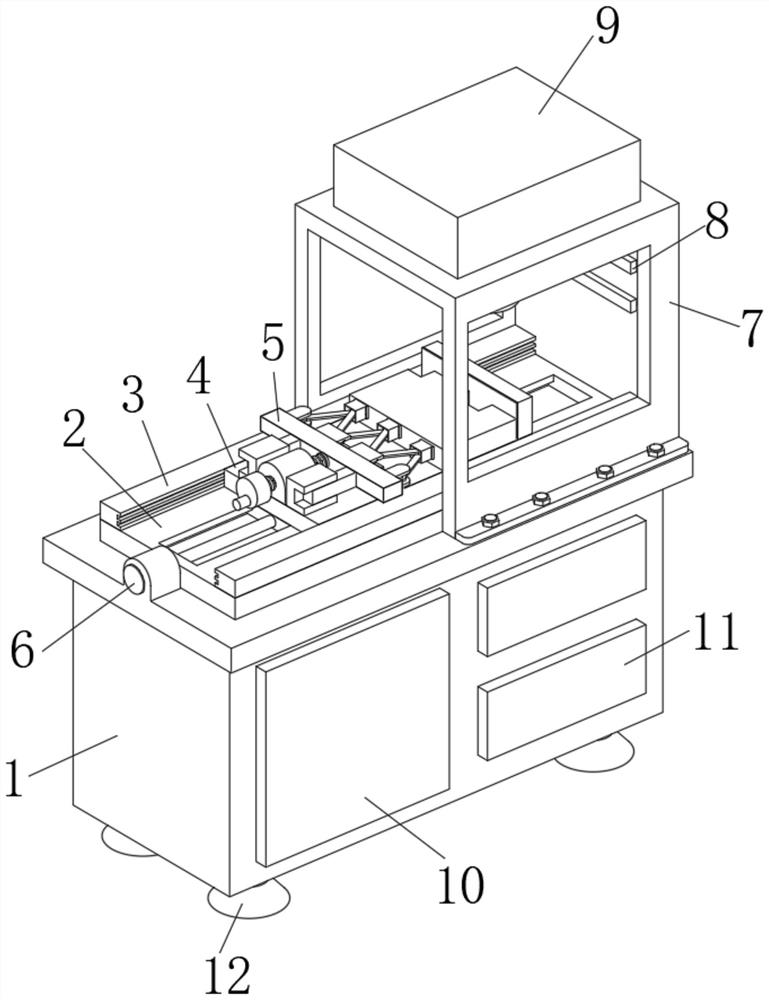

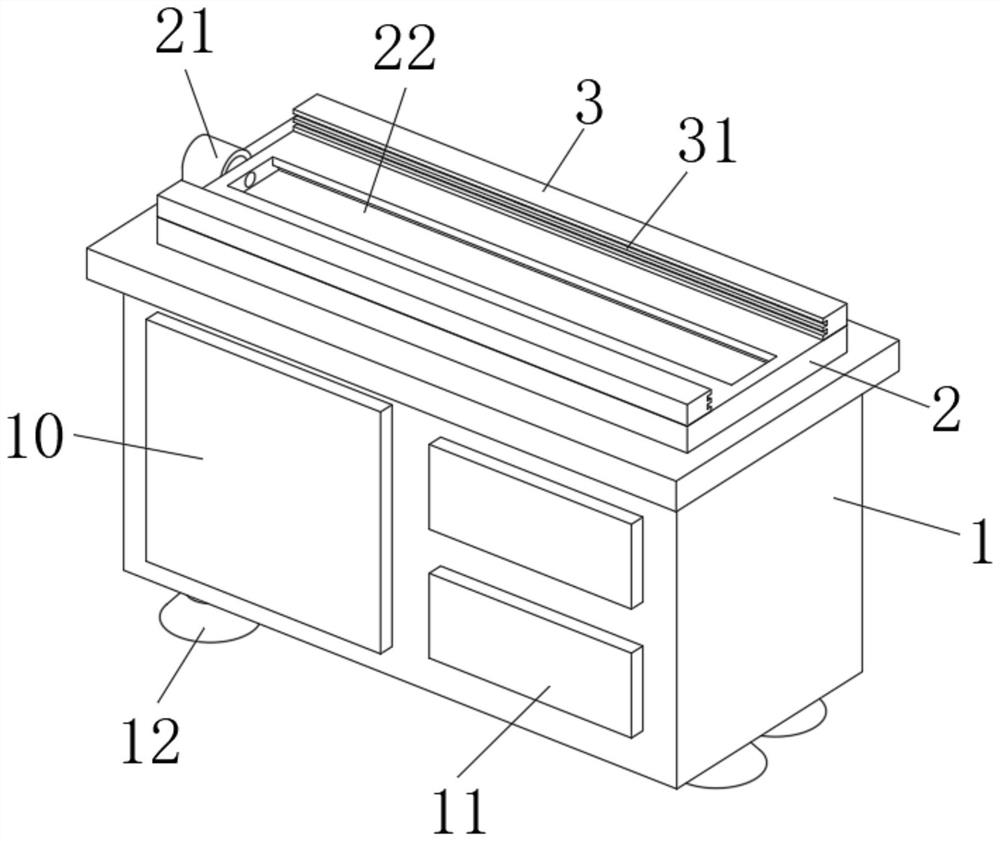

[0034] A CNC machining center capable of holding special-shaped workpieces, such as Figure 1-2 As shown, it includes an operating table 1, a fixed backing plate 2 is fixedly installed in the middle of the upper end of the operating table 1, a fixed seat 21 is fixedly welded on the left end of the fixed backing plate 2, and a chute 22 is opened in the middle of the upper end of the fixed backing plate 2 , a side support plate 3 is fixedly installed on the front and rear sides of the upper end of the fixed backing plate 2, two sliding rails 31 are opened on the opposite ends of the two side support plates 3, and a moving mechanism 4 is slidably connected in the sliding groove 22. And the front and rear ends of the moving mechanism 4 are slidably connected with the slide rails 31, an electric telescopic rod 6 is fixedly installed in the fixed seat 21, and the electric telescopic rod 6 is fixedly connected with the left end of the moving mechanism 4, and the upper end of the moving ...

Embodiment 2

[0037] On the basis of Example 1, as Figure 3-7 As shown in the figure, a CNC machining center capable of clamping special-shaped workpieces includes an operation table 1, a fixed backing plate 2 is fixedly installed in the middle of the upper end of the operating table 1, and a fixed seat 21 is fixedly welded on the left end of the fixed backing plate 2. A chute 22 is opened in the middle of the upper end of the backing plate 2 , a side brace 3 is fixedly installed on both the front and rear sides of the upper end of the fixed backing plate 2 , and two sliding rails 31 are opened on the opposite ends of the two side braces 3 . A moving mechanism 4 is slidably connected in the chute 22 , and the front and rear ends of the moving mechanism 4 are slidably connected with the slide rail 31 . The left end is fixedly connected, the upper end of the moving mechanism 4 is screwed with a positioning mechanism 5 on the right side, and a protective frame 7 is detachably installed on the...

Embodiment 3

[0040] On the basis of Example 1, as Figure 8 As shown in the figure, a CNC machining center capable of clamping special-shaped workpieces includes an operation table 1, a fixed backing plate 2 is fixedly installed in the middle of the upper end of the operating table 1, and a fixed seat 21 is fixedly welded on the left end of the fixed backing plate 2. A chute 22 is opened in the middle of the upper end of the backing plate 2 , a side brace 3 is fixedly installed on both the front and rear sides of the upper end of the fixed backing plate 2 , and two sliding rails 31 are opened on the opposite ends of the two side braces 3 . A moving mechanism 4 is slidably connected in the chute 22 , and the front and rear ends of the moving mechanism 4 are slidably connected with the slide rail 31 . The left end is fixedly connected, the upper end of the moving mechanism 4 is screwed with a positioning mechanism 5 on the right side, and a protective frame 7 is detachably installed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com