Catalyst for treating refractory wastewater, preparation method and preparation equipment

A wastewater treatment and catalyst technology, which is applied in water treatment parameter control, physical/chemical process catalysts, water/sewage treatment, etc., can solve the problems of difficult continuous production of catalysts, insufficient catalyst wastewater treatment capacity, etc., to improve degradation ability, Improve performance and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

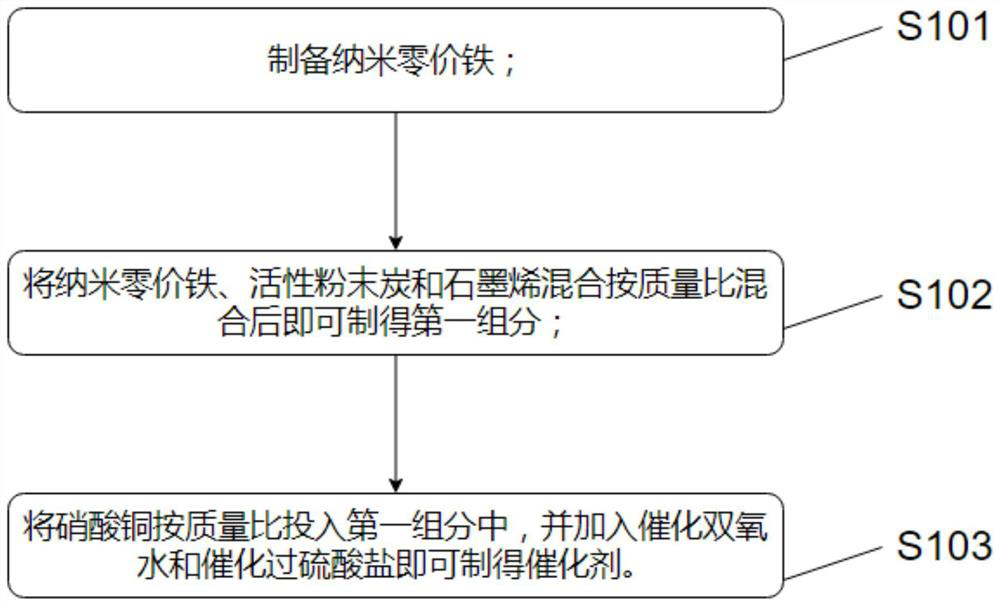

[0025] Adopt the preparation method of the catalyst of a kind of refractory wastewater treatment as described above, comprise the steps:

[0026] S101: preparing nanometer zero-valent iron;

[0027] S102: The first component can be prepared by mixing nano zero-valent iron, activated powdered carbon and graphene according to the mass ratio;

[0028] S103: put copper nitrate into the first component according to the mass ratio, and add catalytic hydrogen peroxide and catalytic persulfate to prepare the catalyst.

[0029] The preparation of nanometer zero valent iron comprises the following steps:

[0030] S201: Put iron balls, iron powder and p-nitrophenol with a diameter of 1.8 to 2 mm into the polytetrafluoroethylene ball grinding pot;

[0031] S202: putting the polytetrafluoroethylene ball milling pot into a microwave oven for microwave-assisted ball milling to prepare nanometer zero-valent iron.

specific Embodiment

[0033] The effluent COD of a disperse dye production plant in Zhejiang is 796-896mg / L in the secondary treatment. The enterprise originally used the Fenton treatment process for the tertiary treatment. The effluent COD has been at 600mg / L, and the removal rate is 20-25%. With equipment, process and catalyst operation, the effluent COD has been maintained at 278-316mg / L, meeting the entry standards of centralized sewage treatment plants at this stage, and the COD is below 500mg / L.

[0034] A catalyst preparation device for refractory wastewater treatment as described above, comprising a mixing structure 10, a synthesis structure 20 and a discharge structure 30, the mixing structure 10 is arranged on the upper side of the synthesis structure 20, and is connected with the synthesis structure 20 The synthesis structure 20 is connected, the synthesis structure 20 is arranged on the upper side of the discharge structure 30, and communicates with the discharge structure 30, the mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com