A composite electrode and its preparation method and application

A composite electrode and electrode technology, which is applied in the field of Co3O4/NPG/Au composite electrode and its preparation, can solve the problems of long time consumption, poor repeatability and poor conductivity of the composite electrode, and achieve high sensor responsiveness, simple preparation method, Effect of Improving Sensing Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

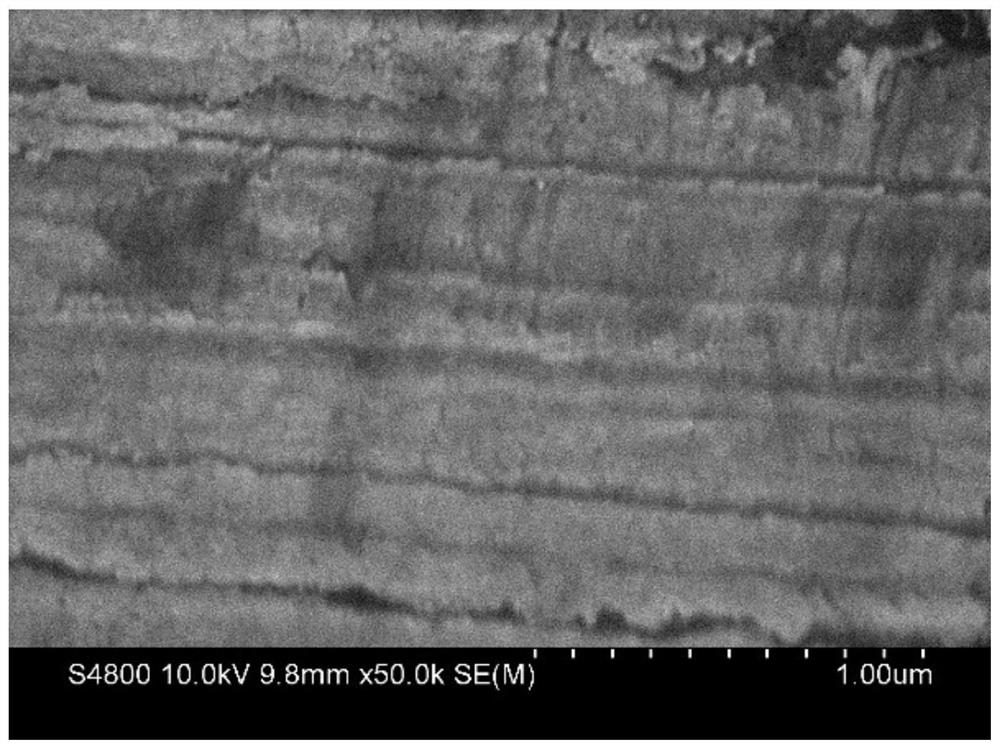

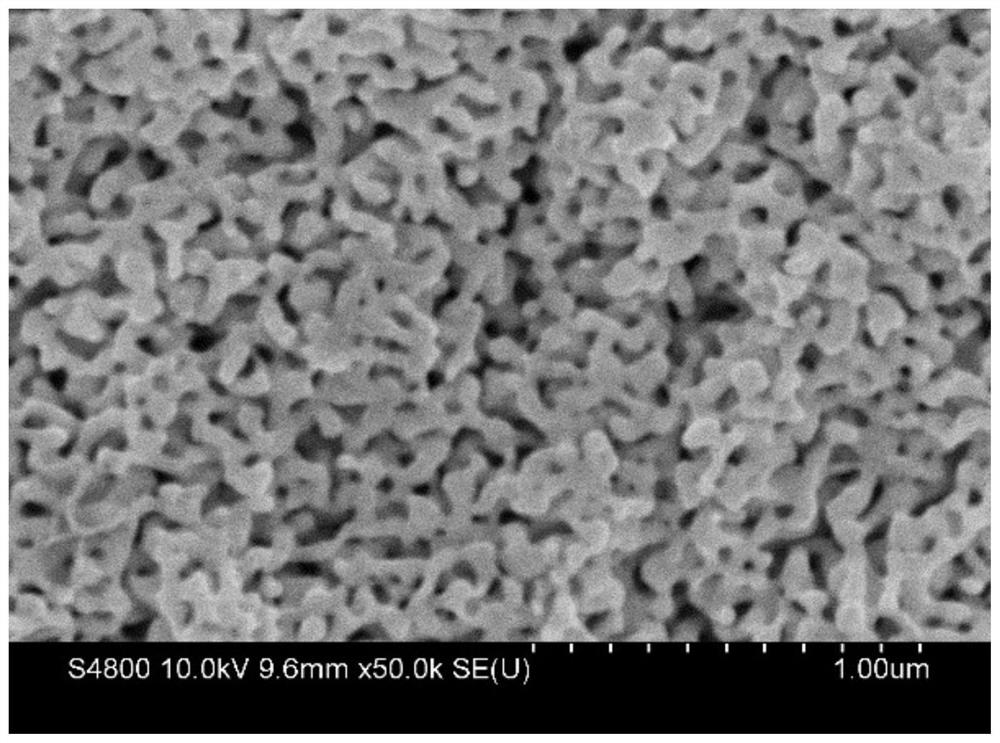

[0046] a Co 3 O 4 / NPG / Au composite electrode, and its preparation method includes the following steps:

[0047] 1) 5.5g potassium citrate, 0.5g sodium citrate, 2g ascorbic acid, 2g p-toluenesulfonic acid, 0.0004g magnesium acetate, 0.05g antimony potassium tartrate, 0.005g propylene glycol block polyether L -64, 0.001g of 3,5-dihydroxybenzyl alcohol (pre-dissolved with ethylene glycol), 1.81g of stannous sulfate and 1.2g of gold potassium citrate were added to 80mL of deionized water in turn, dissolved by ultrasonic, and then added Dilute the volume to 100 mL with deionized water to obtain a gold-tin plating solution;

[0048] 2) The two-electrode constant current mode is adopted, the titanium mesh electrode is used as the anode, and the flat gold electrode is used as the cathode. 2 Electrodeposition was carried out for 15 min under the current density of 100 Å to form an Au-Sn coating on the surface of the flat gold electrode, and then the electrode was washed with deioni...

Embodiment 2

[0066] a Co 3 O 4 / NPG / Au composite electrode, and its preparation method includes the following steps:

[0067] 1) 5.5g potassium citrate, 0.5g sodium citrate, 2g ascorbic acid, 2g p-toluenesulfonic acid, 0.0004g magnesium acetate, 0.05g antimony potassium tartrate, 0.005g propylene glycol block polyether L -64, 0.001g of 3,5-dihydroxybenzyl alcohol (pre-dissolved with ethylene glycol), 1.81g of stannous sulfate and 1.2g of gold potassium citrate were added to 80mL of deionized water in turn, dissolved by ultrasonic, and then added Dilute the volume to 100 mL with deionized water to obtain a gold-tin plating solution;

[0068] 2) Using the two-electrode constant current mode, the titanium mesh electrode is used as the anode, and the flat gold electrode is used as the cathode. 2 Electrodeposition was carried out for 15 min under the current density of 100 Å to form an Au-Sn coating on the surface of the flat gold electrode, and then the electrode was washed with deionized w...

Embodiment 3

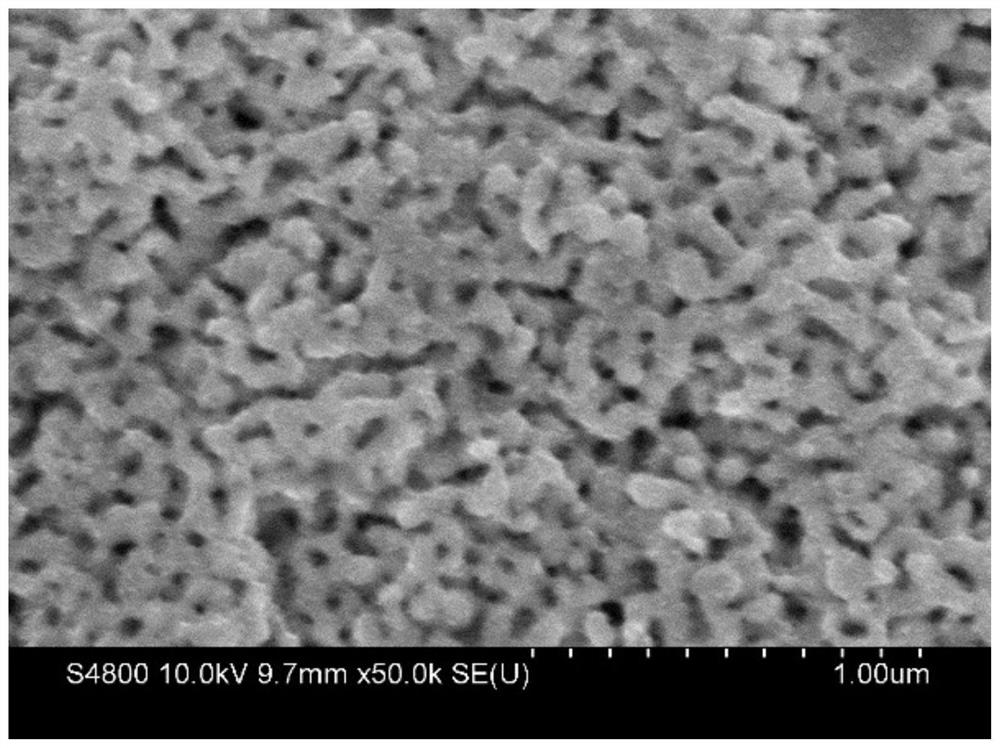

[0074] a Co 3 O 4 / NPG / Au composite electrode, and its preparation method includes the following steps:

[0075]1) 5.5g potassium citrate, 0.5g sodium citrate, 2g ascorbic acid, 2g p-toluenesulfonic acid, 0.0004g magnesium acetate, 0.05g antimony potassium tartrate, 0.005g propylene glycol block polyether L -64. 0.001g of 3,5-dihydroxybenzyl alcohol (pre-dissolved with ethylene glycol), 1.81g of stannous sulfate and 1.2g of gold potassium citrate were added to 80mL of deionized water in turn, dissolved by ultrasonic, and then added Dilute the volume to 100 mL with deionized water to obtain a gold-tin plating solution;

[0076] 2) The two-electrode constant current mode is adopted, the titanium mesh electrode is used as the anode, and the flat gold electrode is used as the cathode. 2 Electrodeposition was carried out for 15 min under the current density of 100 Å to form an Au-Sn coating on the surface of the flat gold electrode, and then the electrode was washed with deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com