Pneumatic tool wear early warning system and early warning method thereof

A technology of pneumatic tooling and early warning system, which is used in measuring devices, instruments, measuring fluid pressure, etc., can solve the problem of difficult to achieve early warning of pneumatic tooling wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

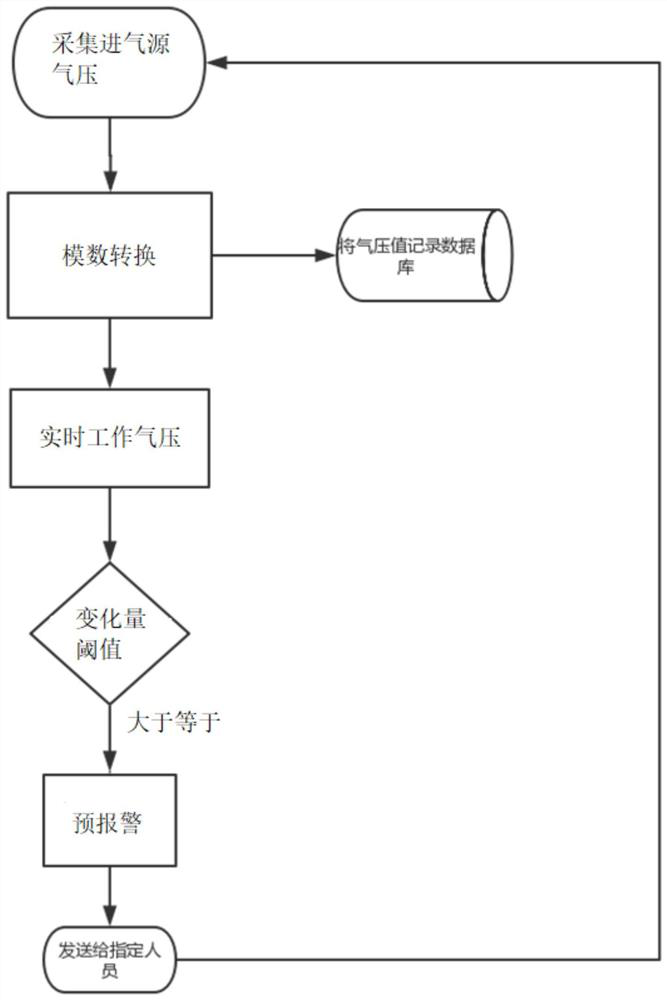

[0088] The present invention provides a first embodiment of a method for early warning of pneumatic tool wear, which includes the following steps:

[0089] 1) Collect the real-time working air pressure of the air intake source of the pneumatic tooling;

[0090] 2) If the real-time working air pressure change of the intake air source is greater than or equal to the preset air pressure change threshold working condition occurs, it is judged that the pneumatic tooling is worn, and an early warning of tooling wear is output.

[0091] The preset air pressure change threshold is 100%-1000% air pressure change, and this embodiment adopts 100%, 200%, 300%, 400%, 600%, 700%, 800%, 900% or 1000%.

no. 2 example

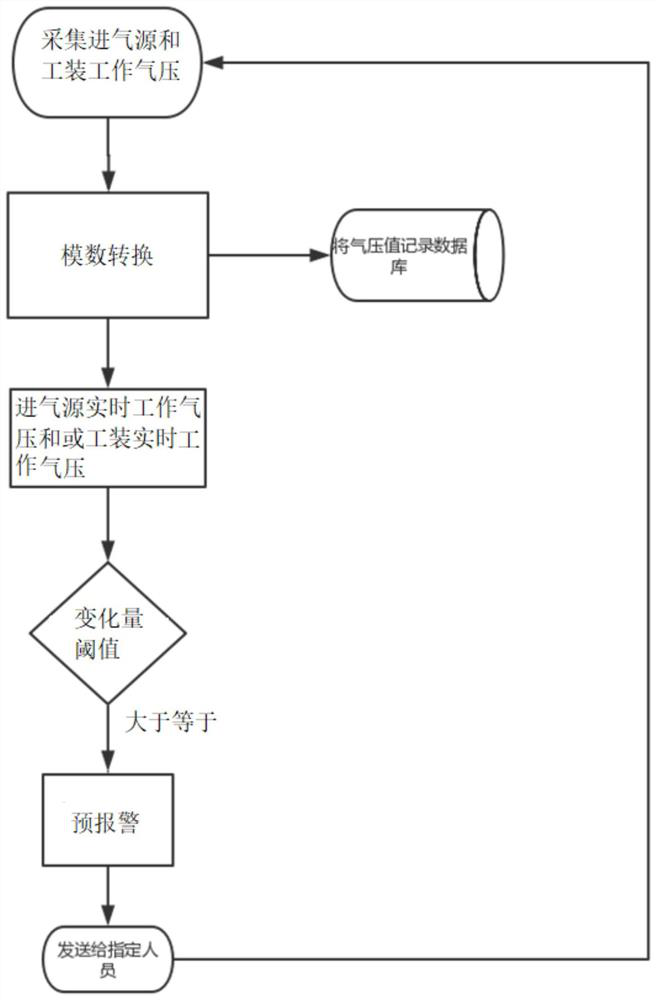

[0092] The present invention provides a second embodiment of a method for early warning of pneumatic tool wear, which includes the following steps:

[0093] 1) Collect the real-time working air pressure of the air intake source of the pneumatic tooling;

[0094] 2) If the real-time working air pressure change of the intake air source is greater than or equal to the preset air pressure change threshold working condition occurs at least twice, then it is judged that the pneumatic tooling is worn, and an early warning of tooling wear is output.

[0095] The preset air pressure change threshold is that the air pressure change amount is 100%-1000% (here, the change amount, that is, the air pressure may be increased or decreased, and may be doubled or halved). 100%, 200%, 300%, 400%, 600%, 700%, 800%, 900%, or 1000%.

no. 3 example

[0096] The present invention provides a third embodiment of a pneumatic tool wear early warning method, which includes the following steps:

[0097] 1) Collect the real-time working air pressure of the air intake source of the pneumatic tooling;

[0098] 2) If the real-time working air pressure change of the intake air source is greater than the preset air pressure change threshold for at least two times within the preset period, it is judged that the pneumatic tooling is worn, and an early warning of tooling wear is output.

[0099] The preset time period range is 0.1ms-10ms. In this embodiment, 0.1m, 0.2ms, 0.2ms, 0.3ms, 0.4ms, 0.5ms, 0.6ms, 0.7ms, 0.8ms, 0.9ms, 1ms, 2ms are used , 3ms, 4ms, 5ms, 6ms, 7ms, 8ms, 9ms or 10ms. The preset air pressure change threshold is 100%-1000% air pressure change, and this embodiment adopts 100%, 200%, 300%, 400%, 600%, 700%, 800%, 900% or 1000%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com