Radiation heating immersion unit cleaning and drying device and drying method thereof

A radiant heating and drying device technology, applied in heating to dry solid materials, drying, dryers, etc., can solve problems such as failure of the function of the dried device, overheating damage to the immersion unit, pollution particles, etc., to avoid acceleration Effects of aging or contamination, improved stability, avoidance of deformation and functional failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

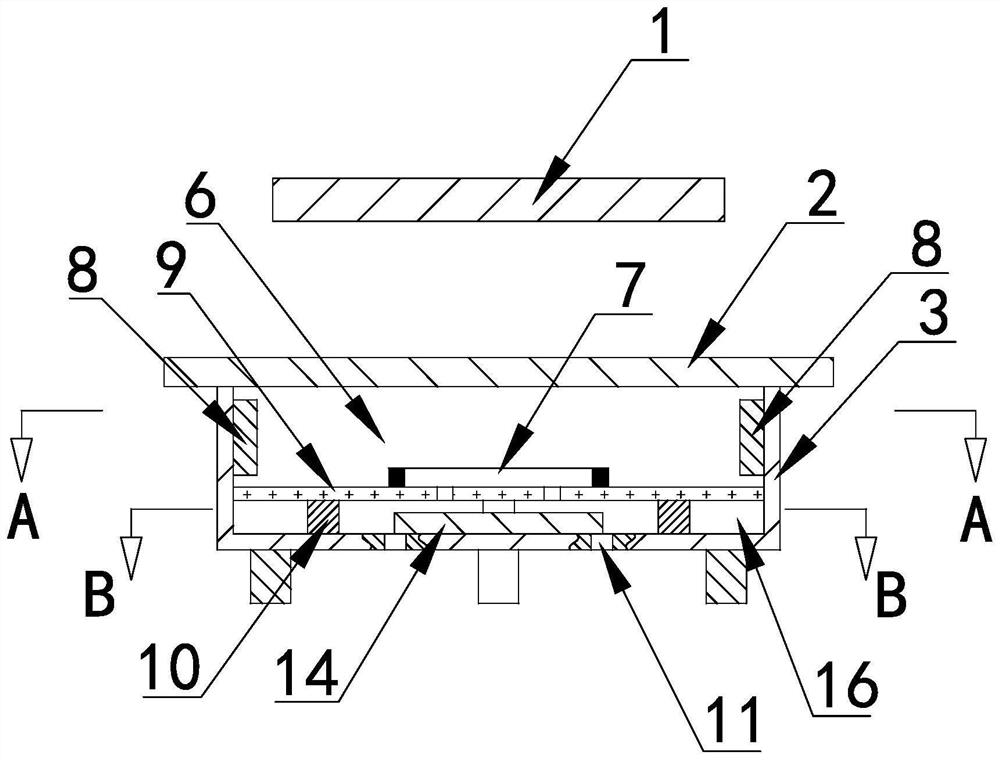

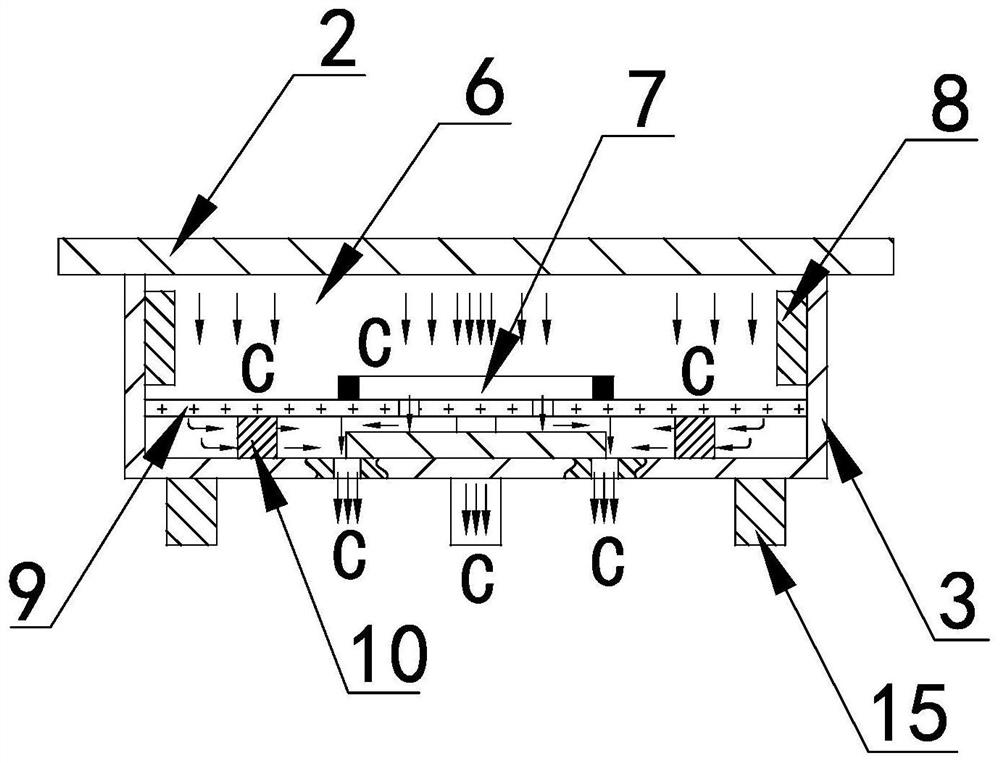

[0038] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 In the shown embodiment, a radiation heating immersion unit cleaning and drying device includes a drying box 3 for drying the immersion unit. The top of the drying box 3 communicates with the outside world. The top of the drying box 3 is placed inside the box, and the top of the drying box 3 is placed with a quartz glass cover 2 for sealing the drying box 3. The quartz glass cover 2 has high light transmission and high cleaning effect, and can be more To a large extent, the drying treatment cleanliness of the immersion unit for drying treatment in the sealed drying box 3 and the infrared radiation drying penetration rate of the radiation heater 1 are guaranteed to improve the drying treatment efficiency; the quartz glass cover 2 can Improve the effectiveness of the radiant heater in heating and drying the immersion unit inside the drying box 3 through the sealing cover, and reduce the secondary poll...

Embodiment 2

[0041] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 In the shown embodiment, a method for cleaning and drying a radiant heating immersion unit includes the following drying treatment method

[0042] A1. with the quartz glass cover described in embodiment 1, the upper end of the drying cabinet is sealed;

[0043] A2. In the sealed drying cabinet, pass into the drying cabinet through the air inlet described in embodiment 1. Stable dry gas, this dry gas has a temperature in a stable range value, makes and feeds the flow rate;

[0044] A3. Stable dry gas enters the upper cavity of the drying box along the air inlet, and the dry gas pushes the air in the upper cavity described in Example 1 to flow downward together, and from the The inter-chamber communication air outlet flows down into the lower cavity described in Embodiment 1 (see image 3 indicated by the arrow C in the middle);

[0045] A4. The stable dry gas pushes the air from the upper cavity a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com