High-temperature-resistant oil pipe joint and preparation method thereof

A technology for oil pipe joints and high temperature resistance, which is applied in the direction of pipes/pipe joints/fittings, pipeline protection, threaded connections, etc. It can solve the problems of poor high temperature resistance of oil pipe joints, failure to find product defects, and inability to inspect product quality. Effects of service life, improvement of adhesion and thickness, and improvement of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

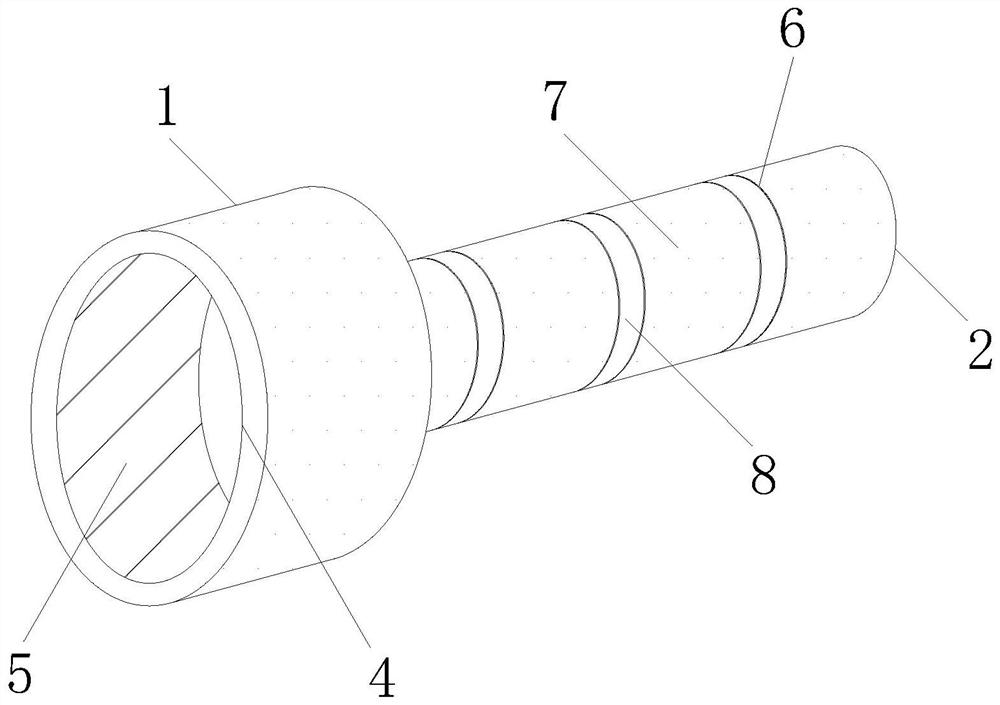

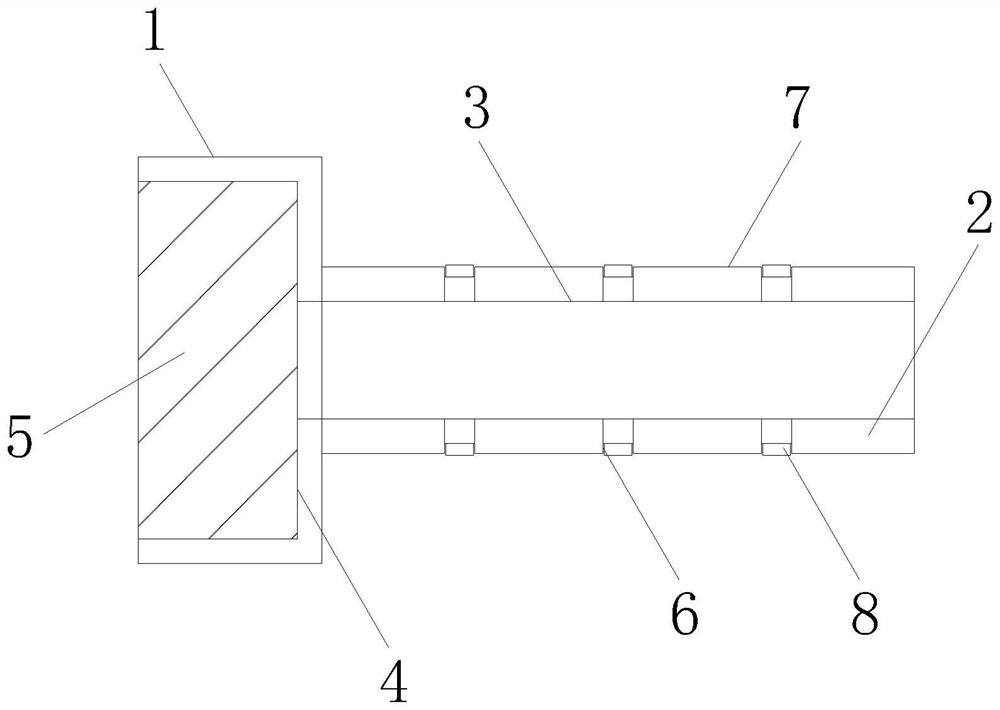

[0035] The specific embodiment is a high temperature resistant oil pipe joint, and its three-dimensional structure schematic diagram is as follows: figure 1 The schematic diagram of its cross-sectional structure is shown in figure 2 As shown, the oil pipe joint includes an inner threaded joint 1 and an insertion rod 2 fixed to the right end of the inner threaded joint 1; wherein, the insertion rod 2 is provided with an inner through hole 3, and the inner threaded joint 1 is provided with an inner through hole 3 that is the same as the inner through hole 3. The groove 4 and the thread 5 of the concentric structure are provided with annular grooves 6 distributed at equal distances on the outside of the insertion rod 2. The annular groove 6 is sleeved with a sealing ring 7, and the surfaces of the inner threaded joint 1 and the insertion rod 2 are provided with high temperature resistant coating. Layer 8.

[0036] The material of the female threaded joint 1 and the plunger 2 is...

Embodiment 2

[0054] When using the preparation method of this technical solution to make oil pipe joints, the steps are as follows:

[0055] Step 1: Blanking: According to the diameter of the oil pipe joint, select the bar of the corresponding specification, the length of the blanking = the length of the oil pipe joint + the blanking allowance, and the blanking allowance is 5mm;

[0056] Step 2: Length finishing: Grind both ends of the bar so that the error between the length of the bar and the length of the tubing joint is less than ±0.3mm;

[0057] Step 3: Turning: Put the bar on the CNC lathe and clamp it, set the cutting speed and feed for rough machining, and turn the bar into a stepped cylindrical material. When the diameter of the stepped cylindrical material is different from the diameter of the oil pipe joint When it is less than 8mm, adjust the cutting speed and feed for finishing until the dimensional error between the stepped cylindrical material and the oil pipe joint is less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com