High-ground-temperature highway tunnel heat insulation and heat dissipation supporting structure and construction method

A technology for highway tunnels and supporting structures, applied in tunnels, tunnel linings, ventilation of mines/tunnels, etc., can solve the problems of tunnel supporting structure safety and construction environment, achieve multiple safety reserves, improve construction environment, and carry capacity. Not reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

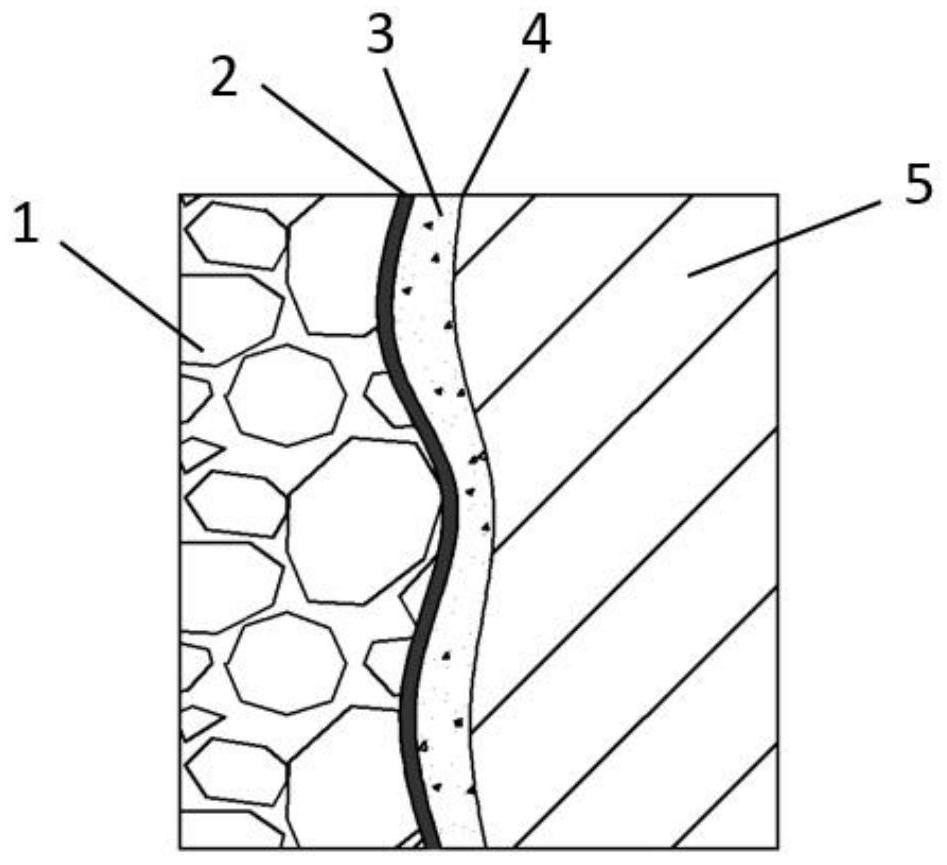

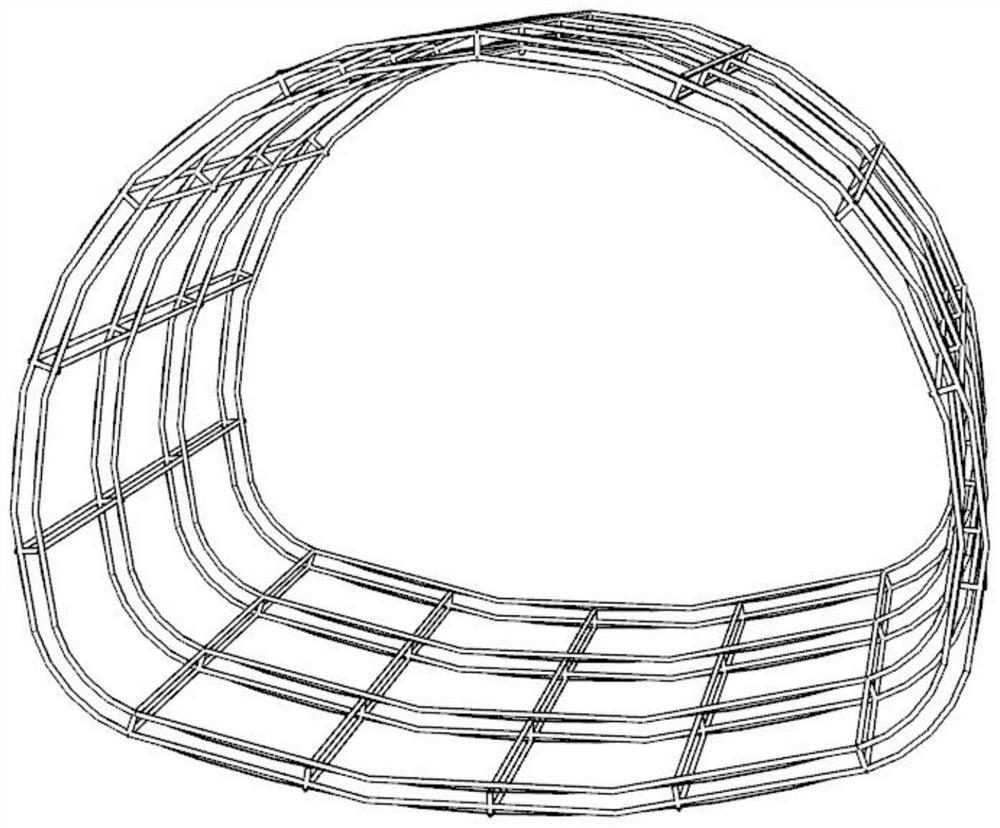

[0029] Embodiment 1: A heat insulation and heat dissipation support structure of a high ground temperature highway tunnel, such as figure 1 As shown, it includes surrounding rock 1, heat insulation layer 2, primary support 3, waterproof layer 4 and secondary lining 5, heat insulation layer 2 is sealed by spraying hard polyurethane heat insulation material on the surface of surrounding rock 1, and primary support 3 is composed of Composed of CF25 steel fiber concrete, a waterproof layer 4 composed of non-woven fabric and II-type polyester tire APP waterproof membrane is installed within the primary support 3, and the secondary lining 5 steel bar is replaced with a steel pipe, which is connected with the air compressor and the air pump. Form a ventilation and heat dissipation structure.

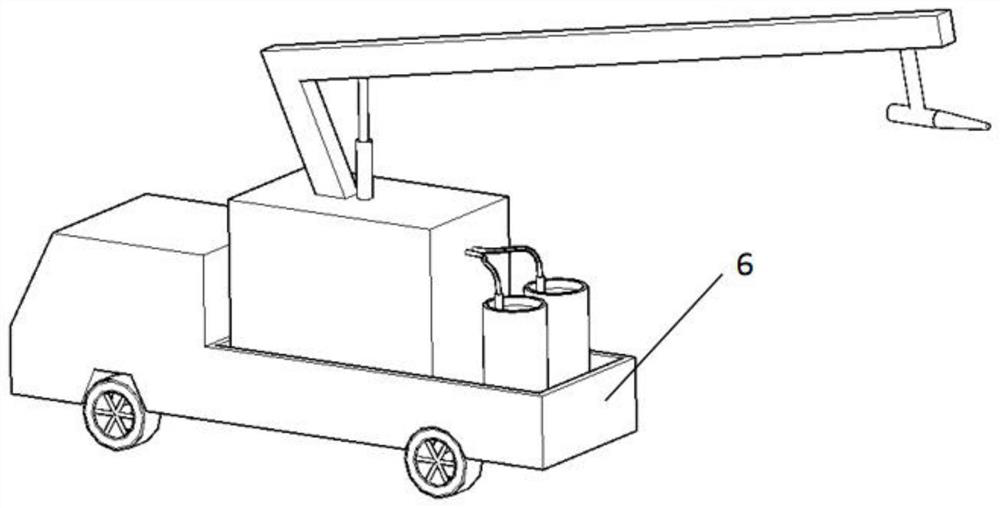

[0030] Such as figure 1 with figure 2 As shown, during specific implementation, according to the ratio of 1:1 (mass ratio), the polyurethane rigid foam combination polyether and isocyanate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com