Gallium oxide doped tin oxide ceramic target material and preparation method thereof

A ceramic target material and tin oxide technology, which is applied in the field of gallium oxide doped tin oxide ceramic target material and its preparation, can solve the problems such as the difficulty of densification of tin oxide ceramics, and improve the density and electrical properties, improve the density, Effect of lowering densification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

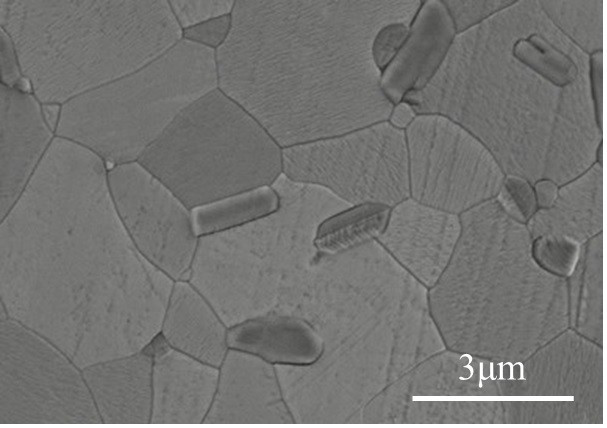

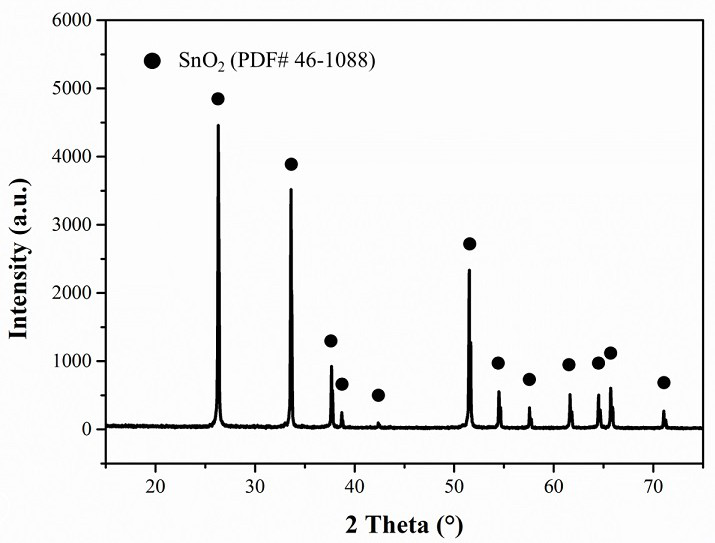

[0027] The preparation method of highly dense tin oxide doped ceramics and pressureless sintering thereof comprises the following steps:

[0028] Step 1, high-density tin oxide doped ceramics, the raw materials are prepared according to the mass percentage, which is composed of the following components: 95% of nano-scale high-purity tin oxide powder, and 5% of nano-scale high-purity gallium oxide powder. In addition, take 0.7% ammonium polyacrylate of the above powder mass as a dispersant, weigh 0.8% of the above powder mass polyvinyl alcohol as a binder, and add 70% of the above powder mass pure water to prepare a slurry;

[0029] Step 2: Put the above-mentioned powder mixture, ammonium polyacrylate, pure water and three specifications of zirconia balls into a 1L zirconia ball mill tank, and mix and ball-mill the powder on the ball mill. The ball mill needs to be carried out for 48 hours. The speed of the ball mill is 260r / min; after the ball milling is completed, add polyvin...

Embodiment 2

[0035] The preparation method of highly dense tin oxide doped ceramics and pressureless sintering thereof comprises the following steps:

[0036] Step 1, high-density tin oxide doped ceramics, the raw materials are prepared according to the mass percentage, which is composed of the following components: 90% of nano-scale high-purity tin oxide powder, and 10% of nano-scale high-purity gallium oxide powder. In addition, take 2% of the aforementioned total mass of ammonium polyacrylate as a dispersant, weigh 2% of the aforementioned total mass of polyvinyl alcohol as a binder, and add 70% of the above-mentioned powder mass of pure water to prepare a slurry;

[0037]Step 2: Put the above-mentioned powder mixture, ammonium polyacrylate, pure water and three specifications of zirconia balls into a 1L zirconia ball mill tank, and mix and ball-mill the powder on the ball mill. The ball mill needs to be carried out for 48 hours. The speed of the ball mill is 240r / min; after the ball mi...

Embodiment 3

[0043] The preparation method of highly dense tin oxide doped ceramics and pressureless sintering thereof comprises the following steps:

[0044] Step 1, high-density tin oxide doped ceramics, the raw materials are prepared according to the mass percentage, which is composed of the following components: 98% of nano-scale high-purity tin oxide powder, and 2% of nano-scale high-purity gallium oxide powder. In addition, 0.5% of the aforementioned total mass of ammonium polyacrylate was weighed as a dispersant, and 0.5% of the aforementioned total mass of polyvinyl alcohol was weighed as a binder, and 70% of the mass of the above powder was added to prepare the slurry with pure water;

[0045] Step 2: Put the above-mentioned powder mixture, ammonium polyacrylate, pure water and three specifications of zirconia balls into a 1L zirconia ball mill tank, and mix and ball-mill the powder on the ball mill. The ball mill needs to be carried out for 48 hours. The speed of the ball mill is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com