The method for preparing high-entropy oxide ceramic material is simple and low in consumption

A technology of oxide ceramics and ceramic raw materials, which is applied in the field of simple and low-consumption preparation of high-entropy oxide ceramic materials, which can solve the problems of coarse ceramic grains, high sintering temperature, and long sintering time, so as to increase the diffusion rate and reduce the sintering rate. The effect of short temperature and sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

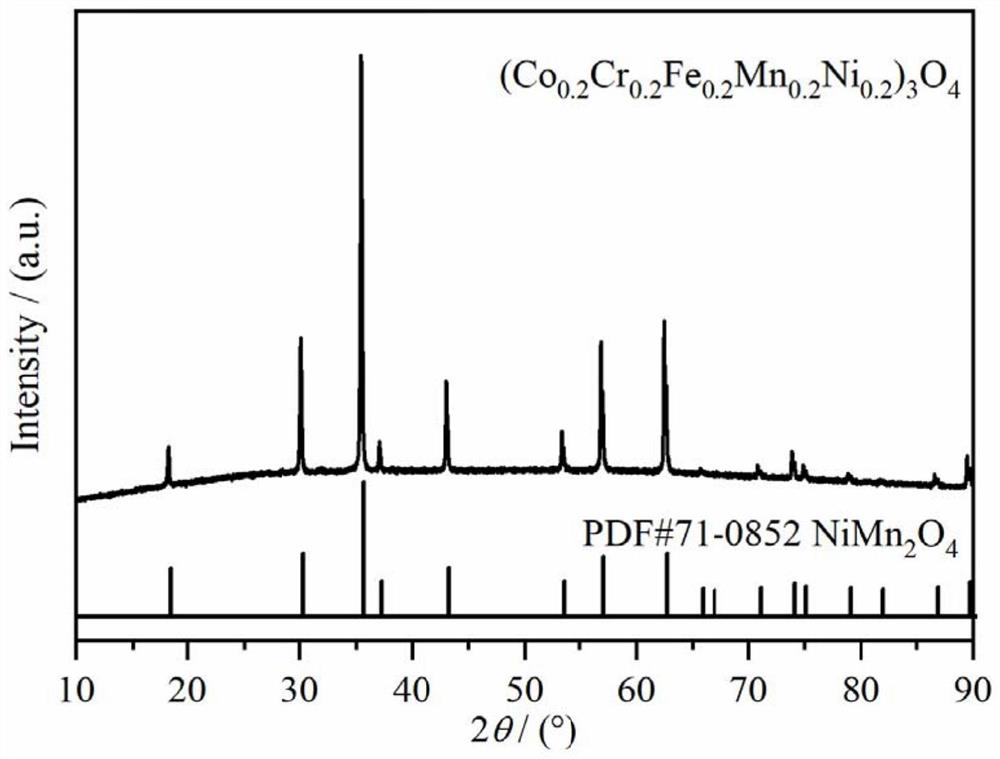

[0041] Embodiment 1: spinel structure (chemical general formula M 3 o 4 , M is a metal element) the preparation method of high-entropy oxide ceramic material comprises the steps:

[0042] (1) Weigh raw materials: Weigh the following various oxide powders of equal metal atoms (0.03mol): cobalt tetroxide, 2.4080g; dichromium oxide, 2.2798g; ferric oxide, 2.3154g; manganese oxide, 2.1281g ; Nickel oxide, 2.2408g, 11.3721g in total;

[0043] (2) Particle refinement: Add 11.3721g of raw material powder and 95g of deionized water into the ball mill tank of the planetary ball mill. The mixed slurry is dried in a blast drying oven, followed by grinding to obtain a fine powder;

[0044] (3) Discharge plasma treatment: under vacuum conditions, take 3g of fine powder and add it to the ball milling tank of the discharge plasma ball mill, and turn on the discharge plasma ball mill to perform discharge plasma activation pretreatment on the ball milling beads and the inner wall of the bal...

Embodiment 2

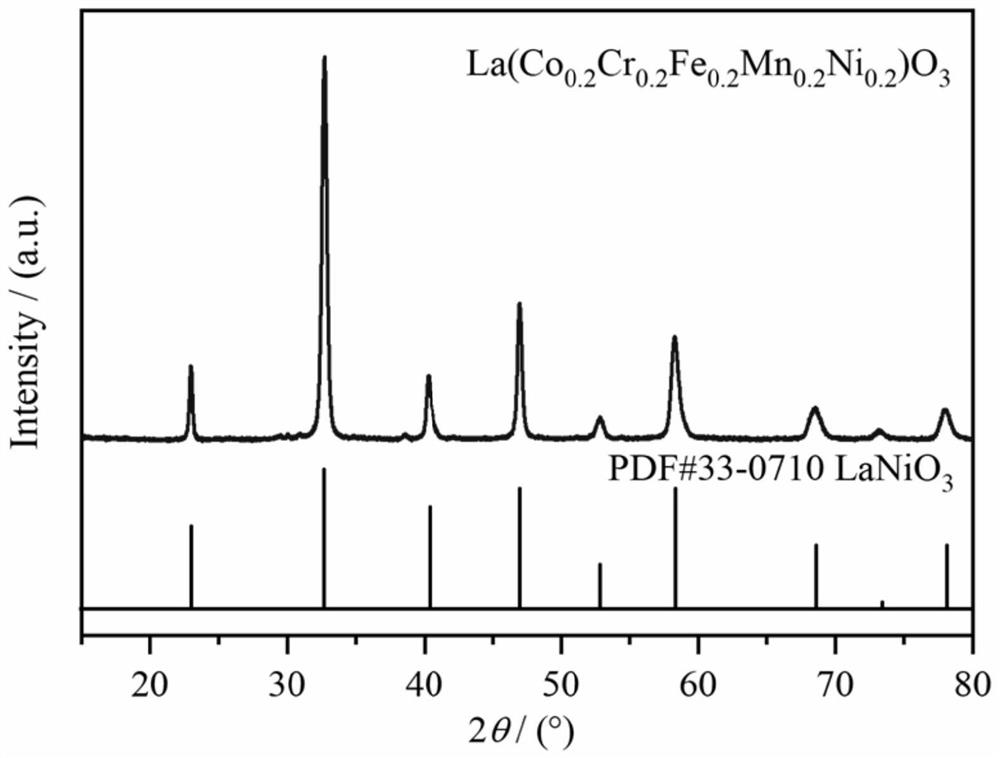

[0050] Embodiment 2: perovskite structure (chemical general formula: ABO 3 , wherein, the A site is lanthanum, and the B site is composed of metal element doping contained in the other five oxides of this embodiment. What is prepared in this embodiment is La(Co 0.2 Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 )O 3 ) A method for preparing high-entropy oxide ceramics, comprising the steps of:

[0051] (1) Weigh raw materials: Weigh various oxide powders of B-site doping elements such as metal atoms, cobalt oxide, 1.1240g; dichromium oxide, 1.1399g; ferric oxide, 1.1977g; manganese dioxide , 1.3041g; nickel oxide, 1.1204g; then weigh lanthanum hydroxide, the raw material of the A-site element, 14.2429g; a total of 20.1290g;

[0052] (2) Particle refinement: Add 20.1290g of the original powder and 109g of raw ethanol into the ball mill tank of the planetary ball mill, the ball-to-material ratio is 8:1, the speed is 300r / min, the ball milling time is 6 hours, and it is prepared by planetary ...

Embodiment 3

[0059] Embodiment 3: the preparation method of sodium chloride structure (chemical general formula is MO, wherein M is metal element) high-entropy oxide ceramic material, comprises the steps:

[0060] (1) Weigh raw materials: Weigh the following various oxide powders such as metal atoms: magnesium oxide, 1.0077g; cobalt oxide, 1.8733g; nickel oxide, 1.8673g; copper oxide, 1.9887g; 8.7715g;

[0061] (2) Particle refinement: Add 8.7715g of raw material powder and 88g of deionized water into the ball mill tank, the ball-to-material ratio is 3:1, the speed is 350r / min, the ball milling time is 8h, and a uniformly mixed slurry is prepared by planetary ball milling , drying the above slurry in a blast drying oven, followed by grinding to obtain a fine powder;

[0062] (3) Discharge plasma treatment: get 3.5g of refined powder and add it to the ball milling tank of the discharge plasma ball mill, turn on the discharge plasma ball mill to carry out discharge plasma activation pretrea...

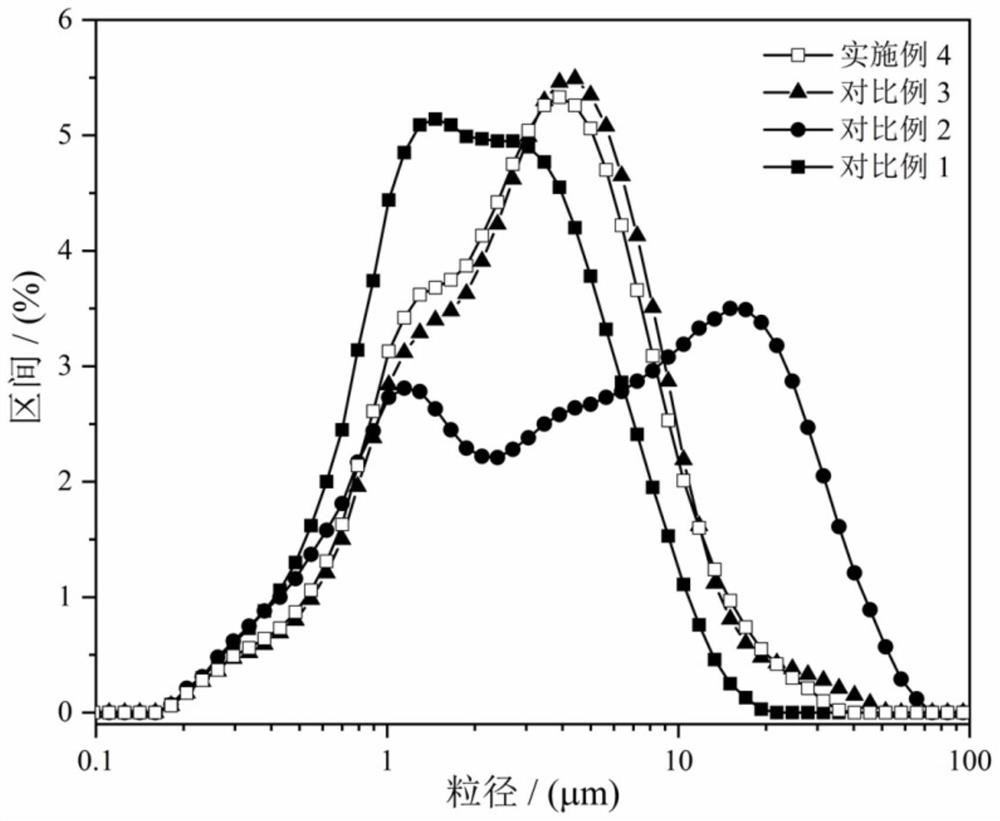

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com