Cutting forming machine for artificial marble production and using method of cutting forming machine

An artificial marble and marble technology, which is applied to manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of inaccurate cutting size accuracy, damage to the physical strength of workers, and stone waste, and achieve flexible and convenient overall structure adjustment. Multi-directional adjustment, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

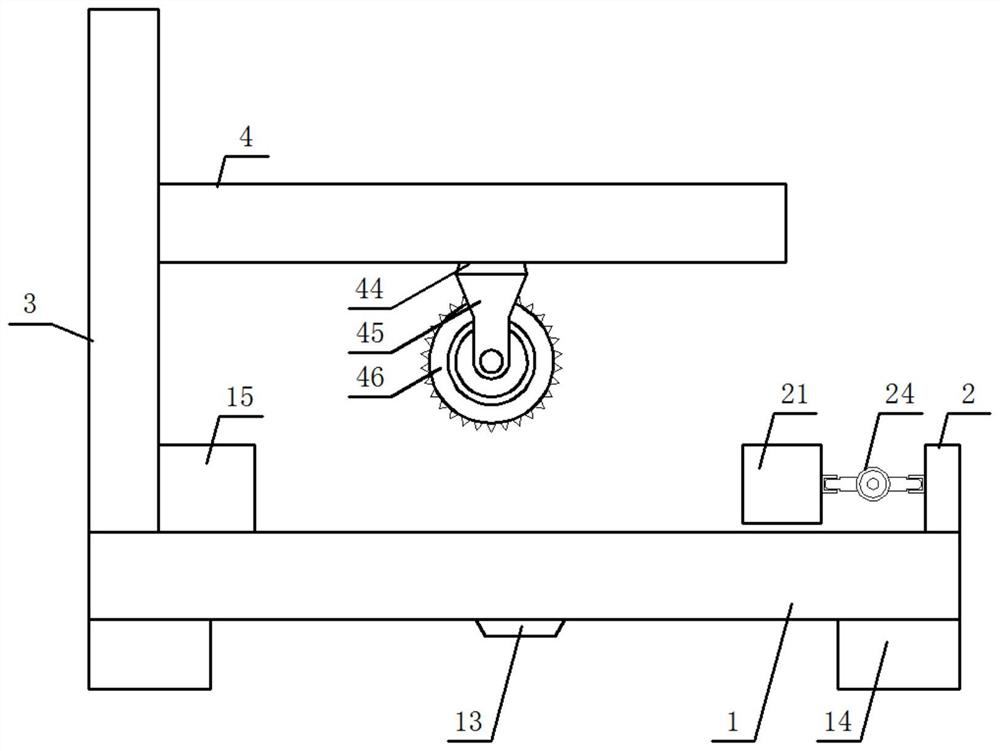

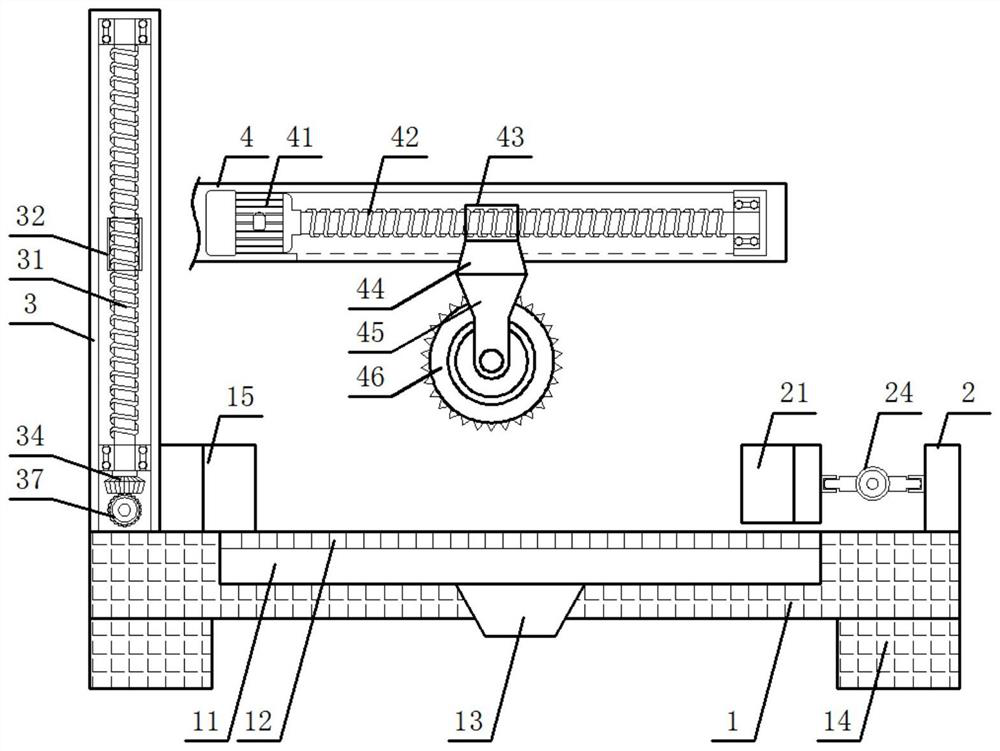

[0033] Embodiment 1: In order to solve the problem of inconvenient adjustment of existing cutting equipment, a cutting and forming machine for artificial marble production is proposed in this embodiment, see Figure 1-6 , including a base plate 1, a clamping mechanism, a lifting mechanism, and a cutting mechanism, the base plate 1 is a rectangular plate placed horizontally and horizontally, and a U-shaped long plate 15 fixed longitudinally is provided on one side of the top surface of the base plate 1. The other side of the top surface of the bottom plate 1 is provided with a fixed plate 2 longitudinally fixed, and the inner side of the fixed plate 2 is equipped with a clamping mechanism, which is located on the outer side of the U-shaped long plate 15 on the top surface side of the bottom plate 1. There is a pair of vertically fixed vertical boxes 3, a lifting mechanism is installed between the two vertical boxes 3, and a vertically placed lifting plate 33 is provided between ...

Embodiment 2

[0039] Example 2: see Figure 7 , in the present embodiment, the present invention also proposes a method for using a cutting and shaping machine for artificial marble production, comprising the following steps:

[0040] Step 1, the biaxial motor 35, the cutting motor 41, and the cutting machine 46 are electrically connected to the external power supply through the power cord respectively, and the artificial marble to be cut is placed in the center on the top surface of the grid plate 12, and the powder after marble cutting is The grid plate 12 falls into the rectangular groove 11, and is discharged through the conical slag discharge cylinder 13, which facilitates timely collection and cleaning of the cutting powder;

[0041] Step 2, by turning the clamping handle 24 to drive the clamping screw 22 to rotate synchronously, since the thread teeth on the two sections of the clamping screw 22 are arranged in reverse symmetrical spirals, the two clamping wire cylinders 23 are drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com